Measurement method and measurement device of coke reactivity

A determination method and reactivity technology, applied in the direction of removing a certain component and weighing, etc., can solve the problems of complex process and large amount of coke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

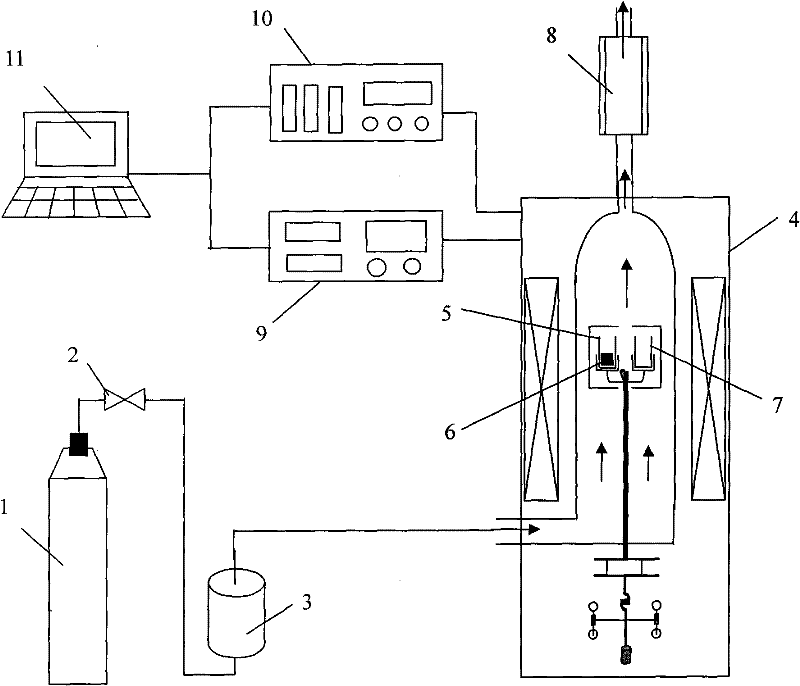

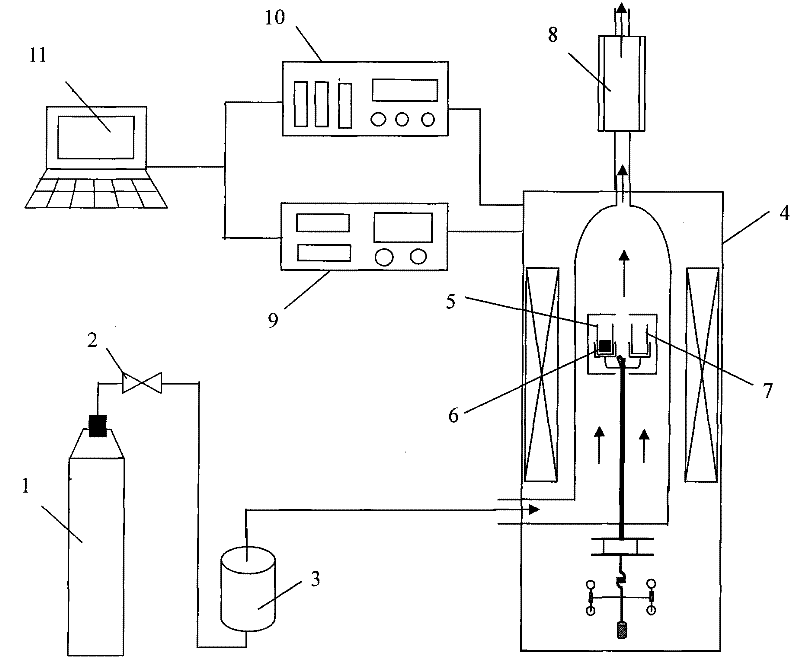

[0013] Technical scheme of the present invention is described in detail as follows:

[0014] A coke reactivity determination method is to use a microcomputer differential thermal analyzer to determine the coke reaction start temperature, and the steps are as follows:

[0015] 1) Take 100-500g of sample coke, dry it in a drying oven at 105°C for 1 hour, and then crush it to 20-156μm;

[0016] 2) Take 30-200mg of crushed coke and put it into a crucible with an inner diameter of 1-4mm, a height of 1-6mm, and a material of 95wt% Al 2 o 3 ;

[0017] 3) Put the crucible in step 2) into the microcomputer differential thermal analyzer, raise the temperature at a heating rate of 5-30°C / min, and raise the temperature to 700-1100°C. During this heating process, pass N 2 Protect;

[0018] 4) When the temperature rises to 700~1100℃, stop N 2 , start to pass CO 2 , CO 2 The flow rate is controlled at 30-100mL / min, the heating rate is controlled at 1-10°C / min, and the reaction time is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com