Method for judging fault and non-fault signals by color codes in on-line fault detection of roll eddy current

A roll and signal technology, which is applied in the field of color code judgment of damaged and non-damaged signals, can solve problems such as large randomness, achieve the effects of repairing damage, improving work quality and efficiency, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Such as figure 1 , 2 As shown,

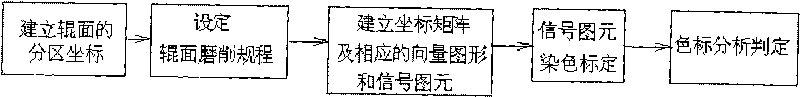

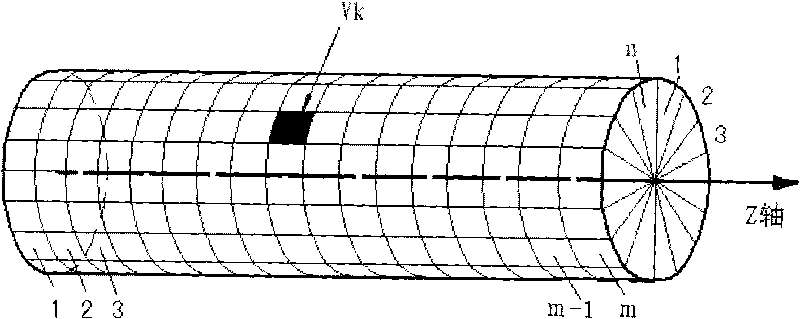

[0039] The process of the method of the present invention is as follows: a. Firstly establish the zone coordinates of the roll surface: divide into m equal parts at equal intervals along the radial direction of the roll, and divide into n equal parts along the axial direction of the roll, and divide the bisectors of m and n The intersecting area, the Vk area in the figure is the coordinate area where the maximum value of the roll surface flaw detection signal is located; b. Set the roll surface grinding rule: make the flaw detection probe and the grinding wheel in the same plane, and the grinding is first , Flaw detection is performed synchronously reciprocatingly along the roller surface afterwards; c. Establish coordinate matrix and corresponding vector graphics: d. Dyeing calibration of signal primitives: e. Color code analysis and judgment.

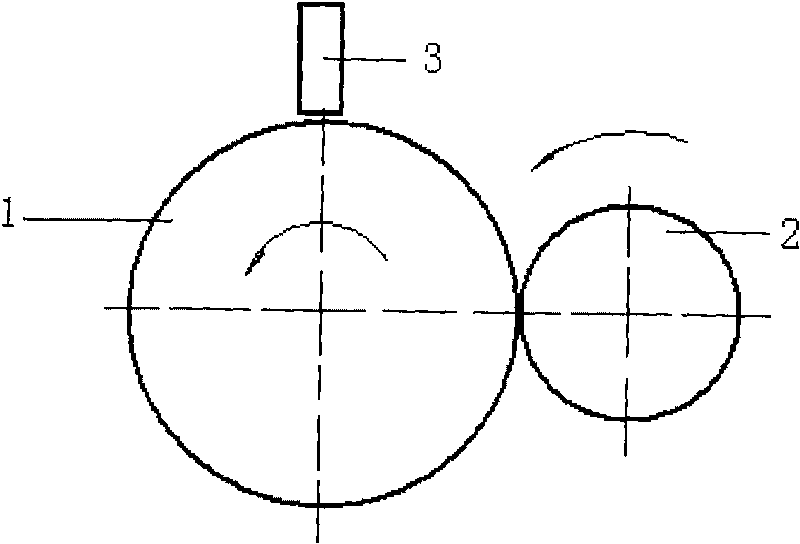

[0040] Such as image 3 As shown,

[0041] While the roll 1 is rotating, the grinding wheel 2 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com