Novel material bulking machine device

A technology for extruders and materials, which is applied to mixers with rotating stirring devices, mixers, chemical/physical/physicochemical fixed reactors, etc., which can solve the problems of high frictional resistance of materials, harmful consequences, and narrow application range, etc. problem, to achieve the effect of small frictional resistance, wide application range and large application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

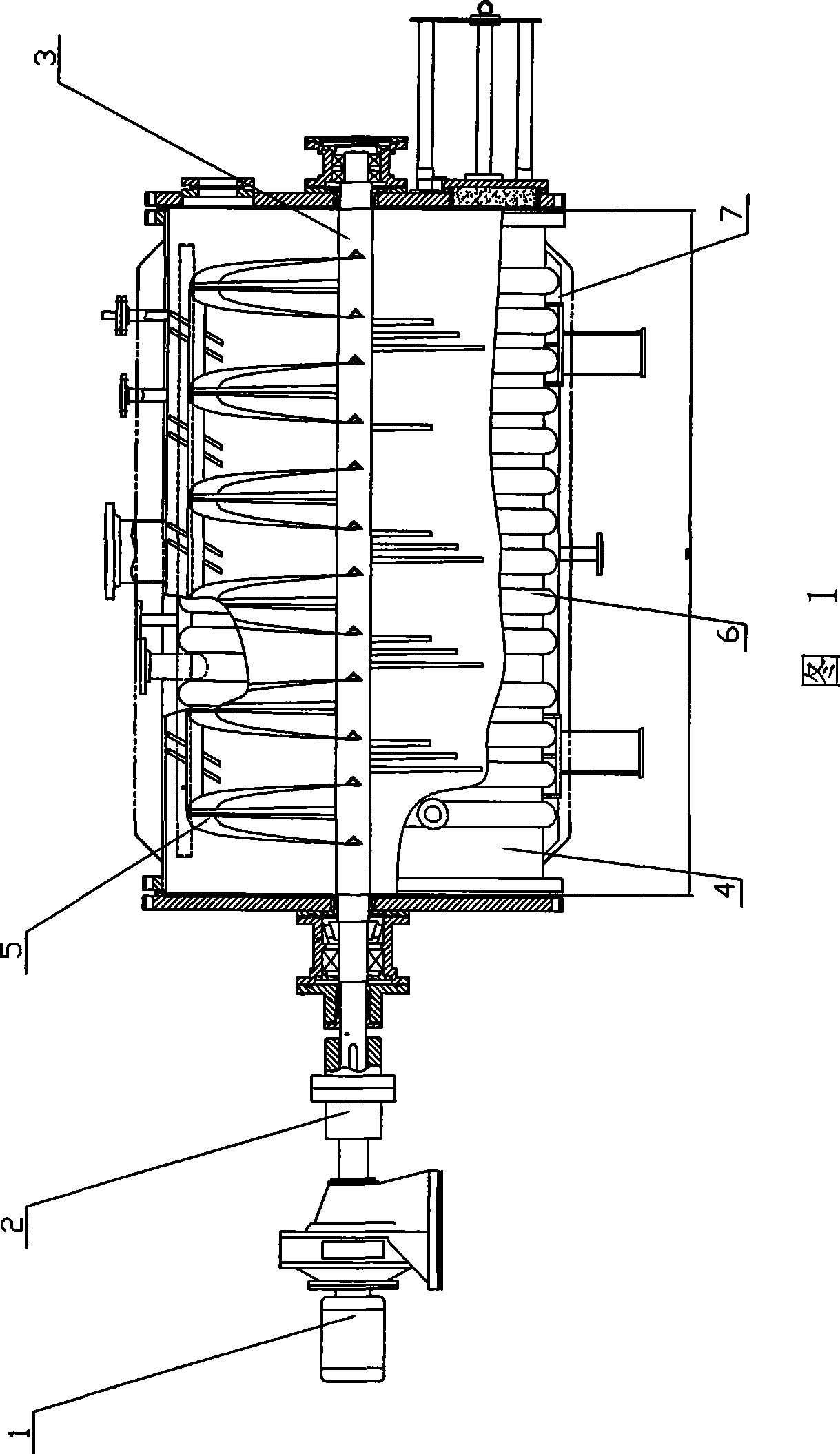

[0008] See figure 1 , the present invention includes a transmission motor 1, an output shaft 2, the output shaft 2 is connected to the transmission shaft 3 through a coupling, the inner cylinder 4 is set on the transmission shaft 3, and in the inner cylinder 4, the transmission shaft 3 is sleeved with a paddle 5 , the paddle 5 is composed of two halves of crescent-shaped spherical caps, see figure 1 , the longitudinal section of the blade 5 is a triangle with an acute arc shape at the apex, and the outer wall of the inner cylinder 4 is reversely connected with a half-coil 6; outside the half-coil 6, the outer wall of the inner cylinder 4 is connected to the jacket 7, and Both ends of the sleeve 7 are connected with the outer wall of the inner cylinder 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com