Catalyst unloading device

A catalyst and vacuum device technology, which is applied in the direction of transportation and packaging, conveying bulk materials, chemical instruments and methods, etc., can solve the problems of reducing the broken rate of catalysts, and achieve the effect of improving the efficiency of unloading agent and reducing the broken rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

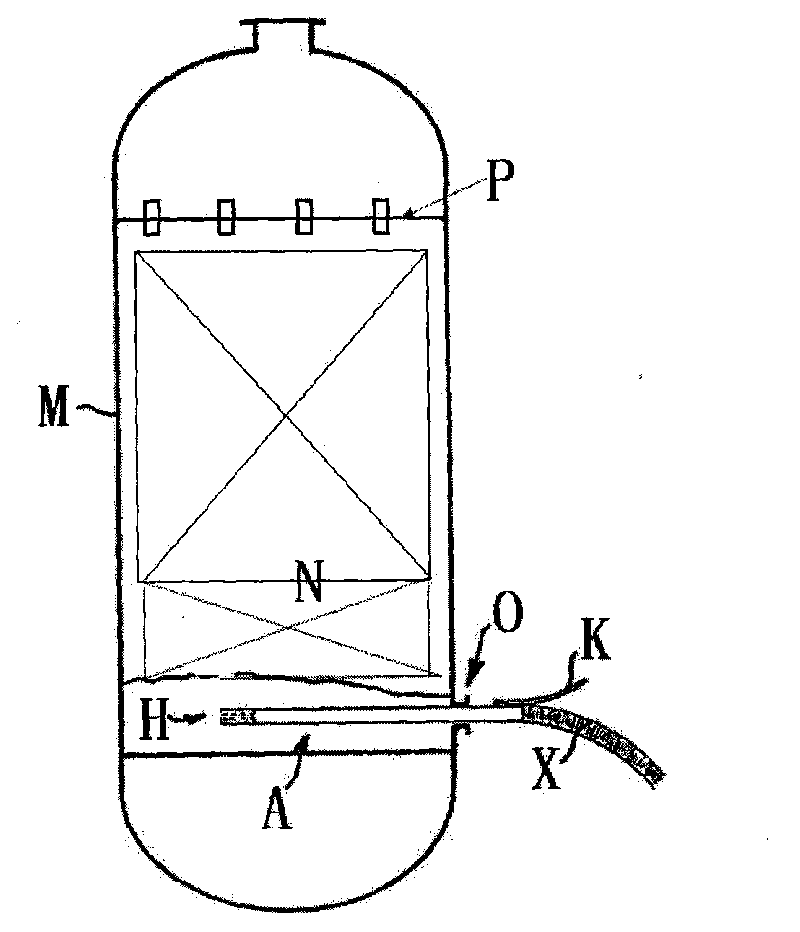

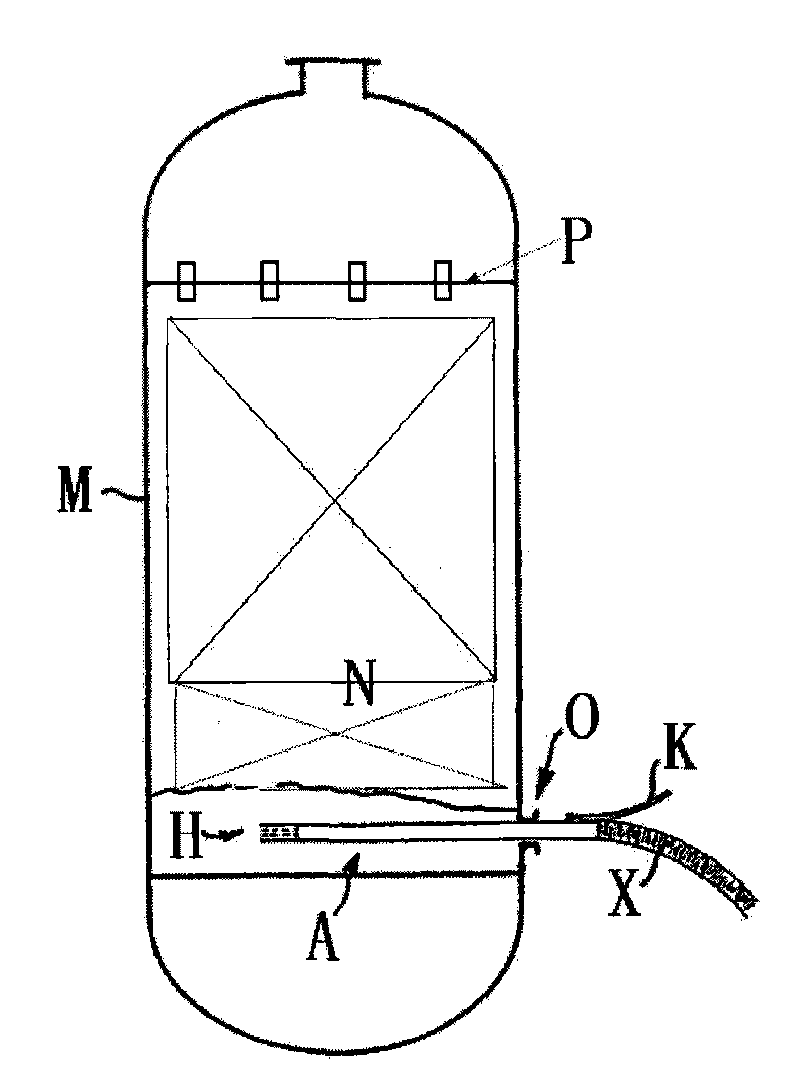

[0015] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

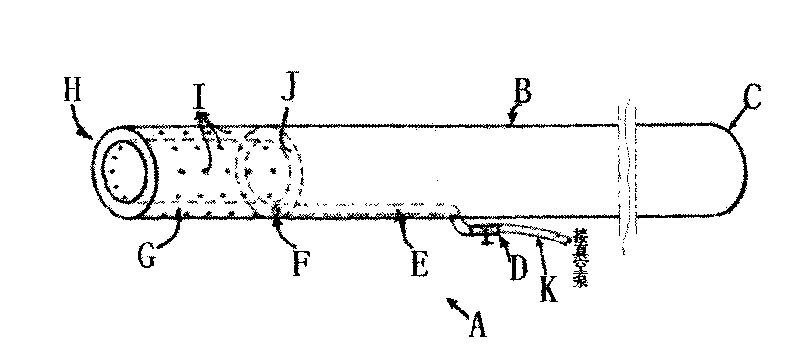

[0016] Such as figure 1 Shown is a schematic perspective view of the vacuum device of the present invention.

[0017] In the first aspect of the present invention, the vacuum device is composed of an extension tube with a determined aperture, and the proximal end of the tube is connected to the suction assembly to transport the catalyst along the inner diameter from the far end of the tube to the proximal end of the tube. The end is equipped with a spray assembly that introduces a large number of compressed gas nozzles into the inner cavity of the distal region of the tube. It is preferable that a large number of compressed gas nozzle holes are in the longitudinal cross-sectional direction of the tube, and it is beneficial that the compressed nozzle directly radially enters the inner cavity of the tube.

[0018] Generally speaking, the spray assembly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com