Internal combustion segmental heat treatment method for pressure container

A technology of pressure vessel and combustion method, used in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of easy deformation of large pressure vessels, and achieve the effect of simplifying heat treatment procedures, quick installation, and avoiding deformation defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

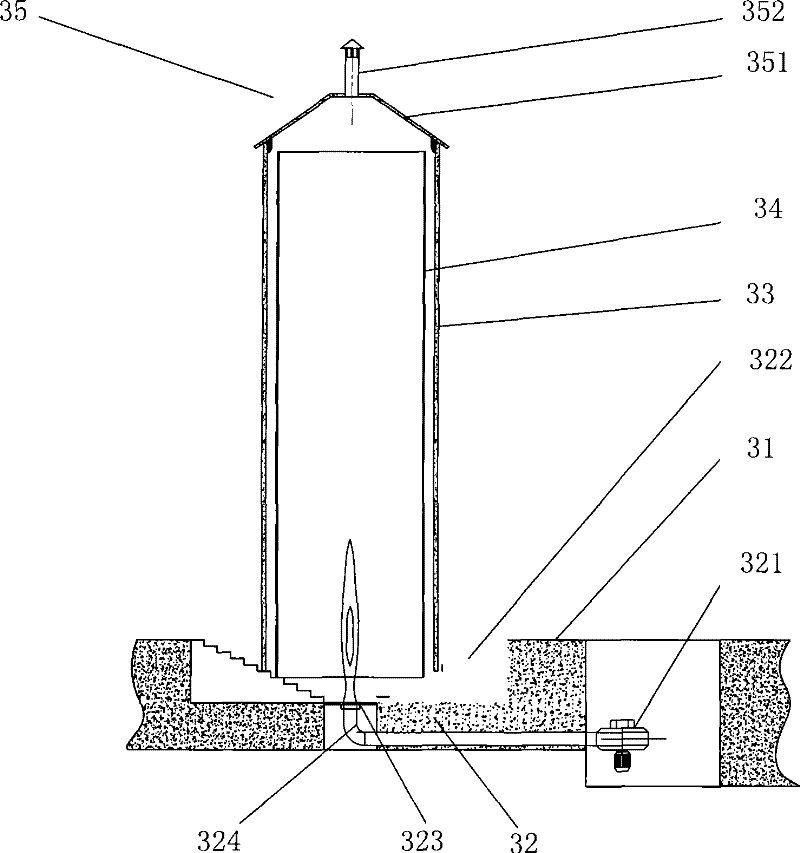

[0033] figure 2 It shows the method of performing staged heat treatment on large pressure vessels at the manufacturing and installation sites of the present invention. Due to the large size of large pressure vessels, fabrication shops usually build large pressure vessels in sections and then ship the sections of the piecewise-built pressure vessels to the site. For ease of description, the present invention refers to a section of a large pressure vessel constructed in sections as a large pressure vessel section 34 .

[0034] Such as figure 2 As shown, the method for carrying out segmental heat treatment of large pressure vessels at the manufacturing and installation sites of the present invention comprises the following steps:

[0035] Build a heat treatment underground facility 32 lower than the ground 31 at the large pressure vessel manufacturing and installation site, and install a burner 321 for combustion heating in the heat treatment underground facility 32;

[0036...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com