Dual high voltage flameproof motor

An explosion-proof, dual high-voltage technology, applied in the field of motors, can solve the problems of energy-saving and high-efficiency, applications where explosive gases cannot be used, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

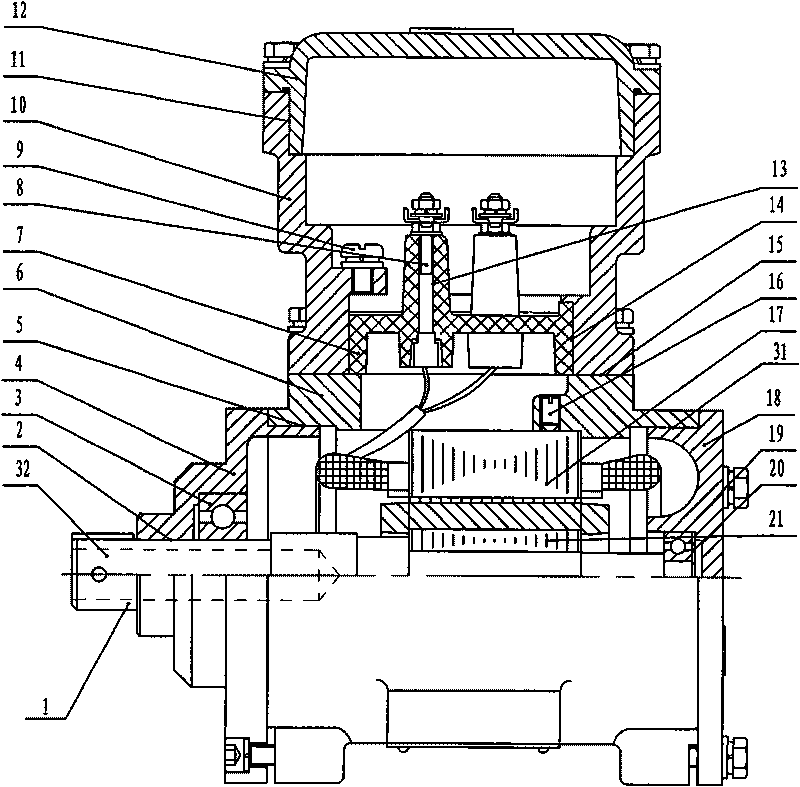

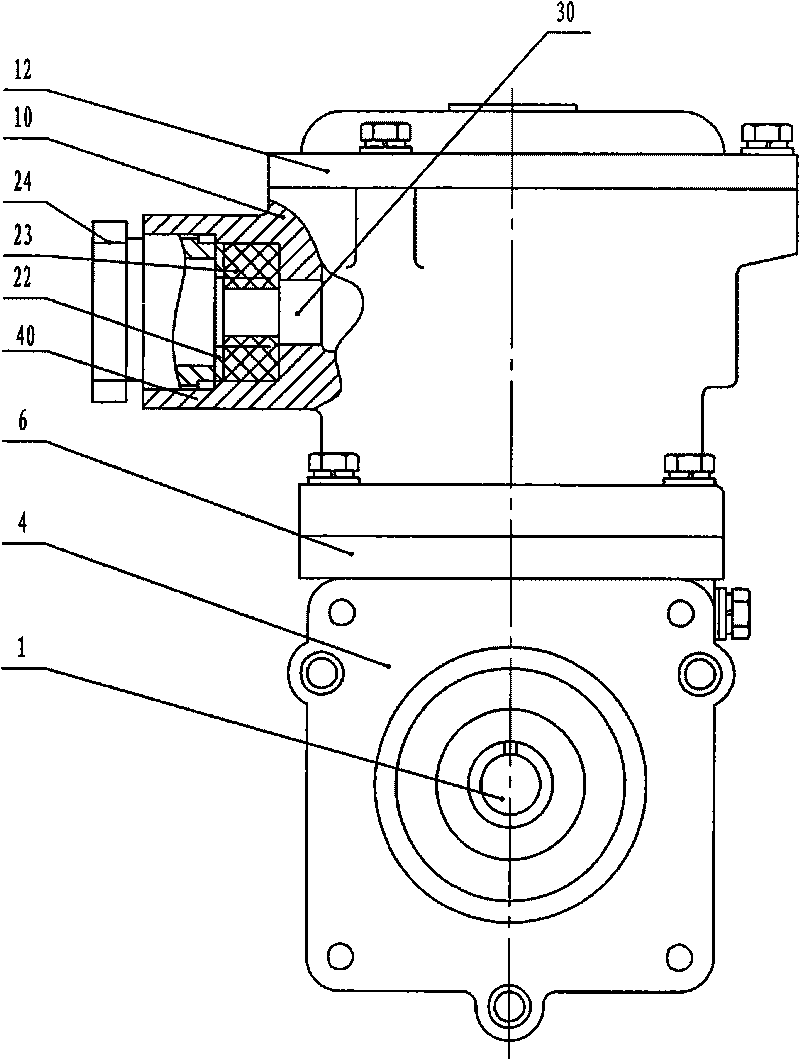

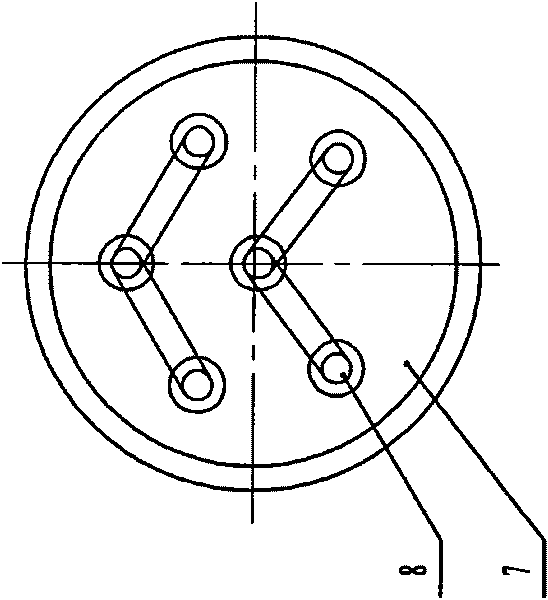

[0014] Such as figure 1 , figure 2 and image 3 As shown, the double high-voltage flameproof motor of the present invention includes a casing 6, and the casing 6 is provided with a main shaft 1, a rotor 21 and a stator 17, and the front end of the main shaft 1 is axially provided with a blind hole 32, which can accommodate the Axial movement of the drive shaft of the main shaft 1 drive connection. The rotor 21 is fixed on the main shaft 1, the stator 17 and the casing 6 are fixedly connected by flat-head screws 16, the front and rear end covers 4 and the rear end covers 18 are respectively arranged on the front and rear of the casing 6, and the front and rear ends of the main shaft 1 are connected to the front end through the bearing 3 and the bearing 19 respectively. The cover 4 and the rear end cover 18 are rotatably connected, and a wave washer 20 is provided between the bearing 19 and the rear end cover 18 . The upper part of the casing 6 is provided with a junction bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com