Thermal transfer printing

A transfer sheet and heating gas technology, applied in transfer materials, transfer printing, rotary printing machines, etc., can solve problems such as poor printing quality, and achieve good printing quality and uniform dye transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

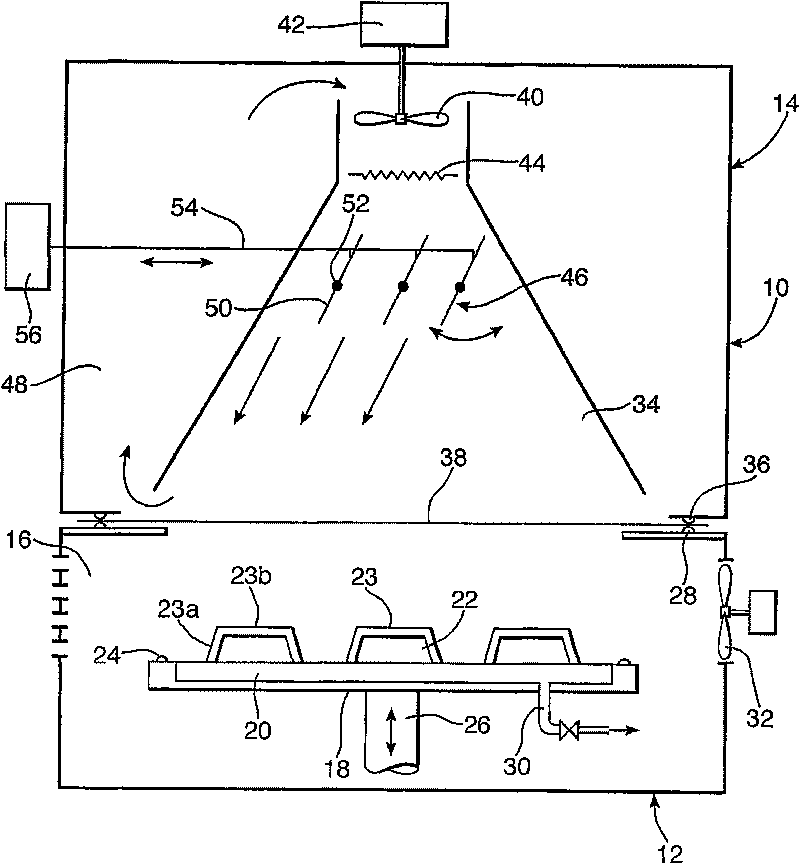

[0076]Form a test image with a consistent neutral gray background. The test images were printed on Pictaflex film sheets using Artainium UV+ inks in an Espon 4400 inkjet printer (Epson is a trademark). This image was transferred to two different substrates in a press as described above. The swing of the blades is sinusoidal with a period of 5 seconds.

[0077] Substrate A) is a 0.5 mm thick aluminum sheet coated with polyester supported on a stand 18 .

[0078] Substrate B) was a 1.8 mm thick molded polycarbonate shell coated with a retransfer varnish in the manner described in US Patent 7,102,660. The shell is supported on a silicone rubber nest 22 and is preheated by running a retransfer cycle without components.

[0079] The pressure conditions are as follows:

[0080] test number

[0081] test number

[0082] The optical density of the transferred image was measured on a grid covering the width and height of each part.

[0083] test number...

example 2

[0086] The test image was formed using narrow vertical and horizontal solid black lines arranged on a consistent half-inch grid test pattern. The test images were printed on Pictaflex film sheets using Artainium UV+ inks in a Mimaki JV5-130S inkjet printer (Mimaki is a trademark). The image was transferred to a 0.5 mm thick polyester covered aluminum sheet in a press as described above. The pressure conditions are as follows:

[0087] test number

[0088] The percent increase in width and height of the transferred image was measured.

[0089] test number

[0090] This means that the moving blades produce lower deformations during the softening phase of the film compared to static diffusers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com