Ink-jet 3D printing supporting structure generation method

A support structure, 3D printing technology, applied in the field of 3D printing, can solve the problems of poor printing quality and product deformation, achieve the effect of good printing quality, prevent internal stress, and improve the surface quality of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

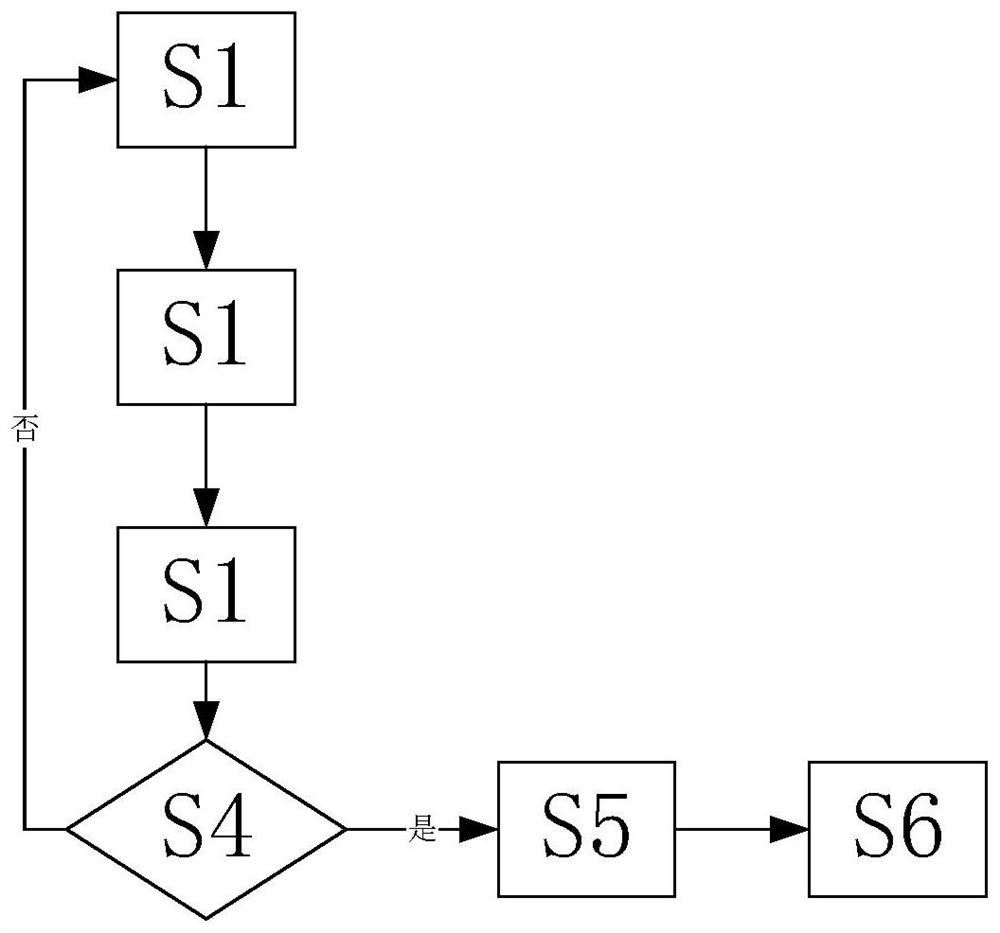

[0036] Such as figure 1 and 2 As shown, a method for generating an inkjet 3D printing support structure, comprising steps:

[0037] S1. Print the supporting ceramic layer by using the fused deposition molding method, and proceed to step S2; the materials of the ceramic layer include printing wires of oxide ceramics such as alumina, zirconia, and calcium oxide.

[0038] S2. Carry out powder spreading and compacting on the ceramic layer, and proceed to step S3; the powder in the powder spreading process is made of the same material as the main part of the workpiece. The material includes alloy powders such as stainless steel, tool steel, copper alloy and high-temperature alloy, which are the same as the main part of the workpiece.

[0039] S3, perform inkjet printing, enter step S4;

[0040] S4. Judging whether to print to the last layer of the support structure, enter step S5; in step S4, when judging whether to print to the last layer of the support structure, if it is the ...

Embodiment 2

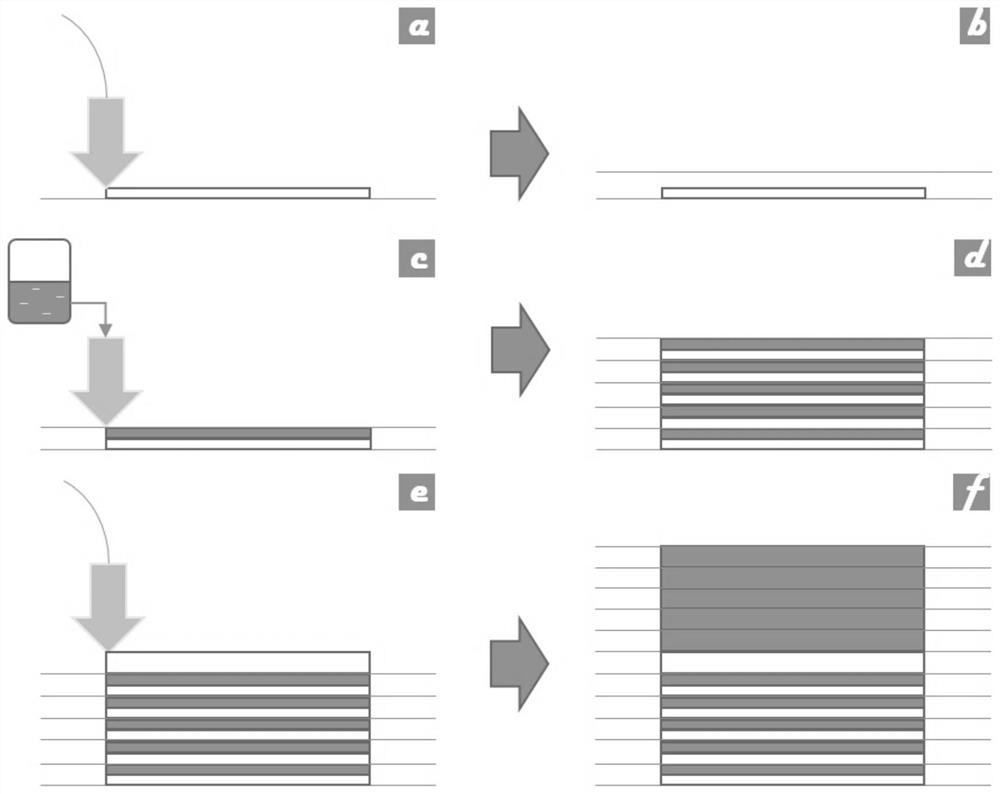

[0048] Such as figure 1 and 2 As shown, two materials that are properly prepared for support sintering include a powder that is the same as the main part of the workpiece and a specific support printing wire that includes oxides such as alumina, zirconia, and calcium oxide. Ceramic printing wire;

[0049] When generating supports, design the support structure as a multi-layer structure, and adjacent layers are composed of different materials;

[0050] The layer thickness of the oxide ceramic material in the multi-layer support should be a specific value, and the specific value should be smaller than the thickness of the workpiece printing layer;

[0051] The part in contact with the lower surface of the workpiece should be made of ceramic material, and the thickness of this layer is equal to the thickness of the printing layer of the workpiece;

[0052] In the printing process of the support, the printing of the support ceramic part with a specific layer thickness is first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com