Compartmental static normal-pressure type pulse bag type dust remover

A bag filter, static technology, applied in the field of environmental protection equipment, can solve the problems of secondary dust adsorption by filter bags, high production and operating costs, incomplete dust removal, etc., to achieve low operating resistance, saving operating costs, and reducing power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

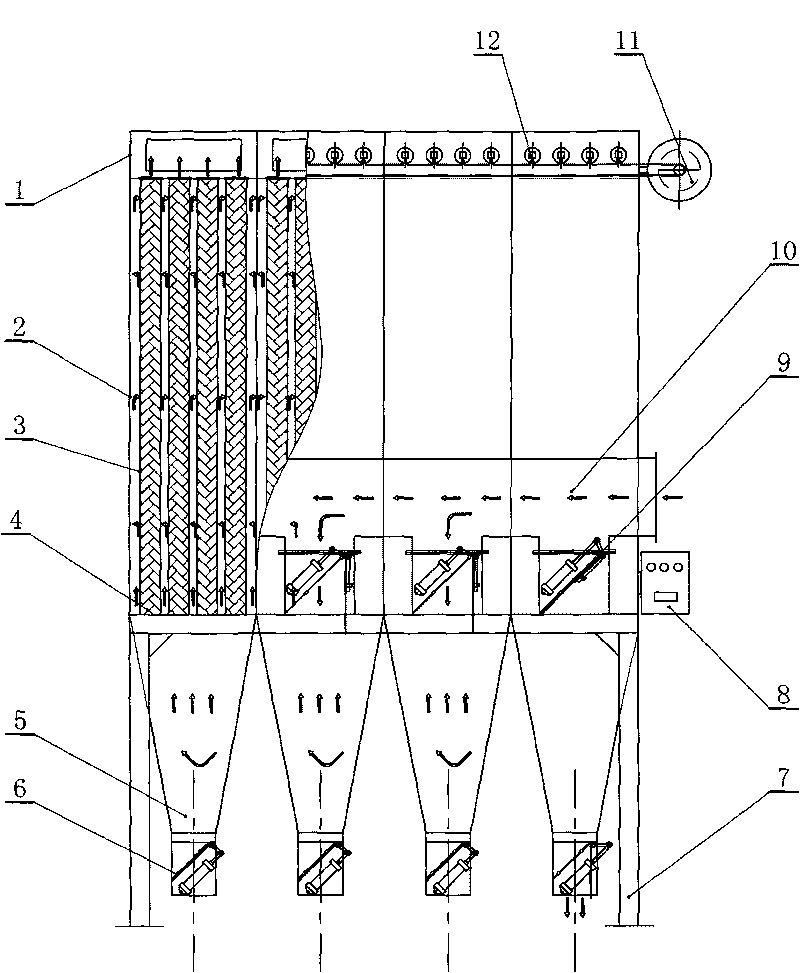

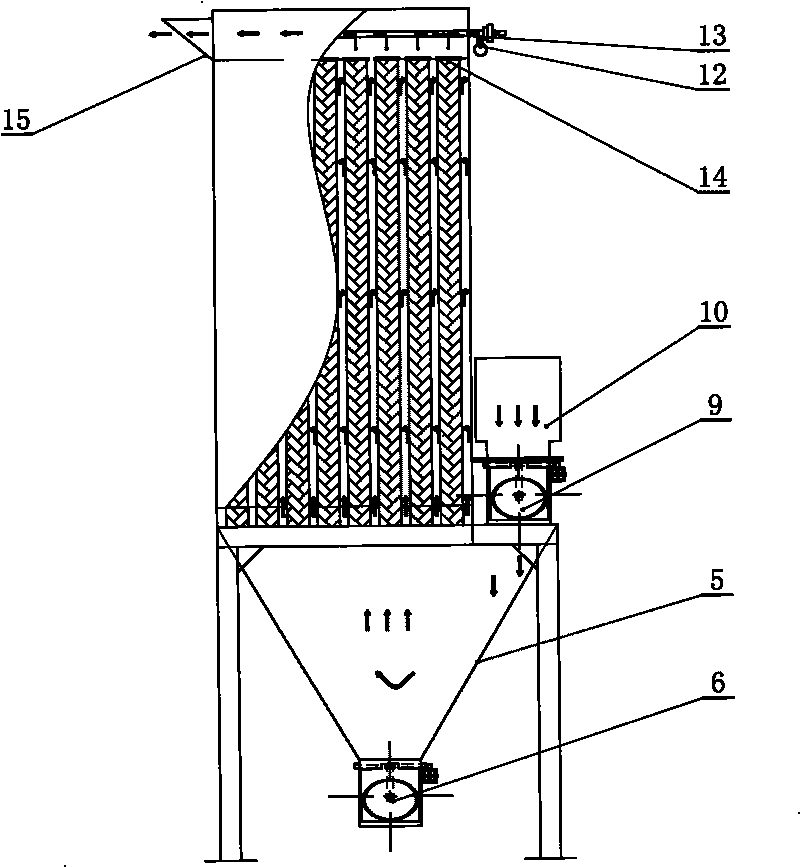

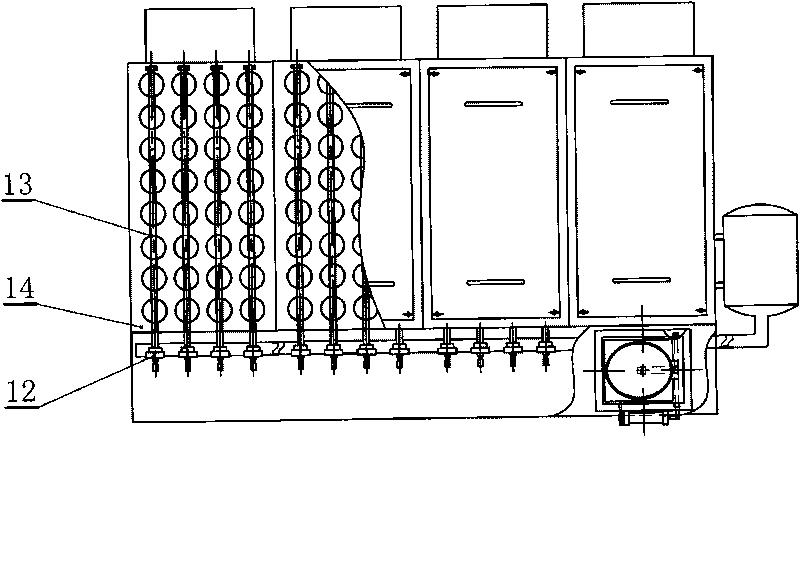

[0010] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0011] A compartmentalized static atmospheric pressure pulse bag filter, such as figure 1 , 2 As shown in , 3, it includes a plurality of dust removal boxes, each dust removal box includes an upper box body 1, the lower end of the upper box body 1 is fixedly connected with the middle box body 2, and the lower end of the middle box body 2 is fixedly connected with the lower box body 5, The upper part of the upper box 1 has an air outlet 15, and each upper box 1 and each middle box 2 are separated by a partition. It is characterized in that the connection between the upper box 1 and the middle box 2 is horizontal The direction is fixedly connected with a porous plate 14, the opening of the porous plate 14 is designed with a filter bag frame 3, the filter bag frame 3 passes through the porous plate 14, the upper end of the filter bag frame 3 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com