Non-leakage reversible automatic exhaust valve

A technology of automatic exhaust valve and exhaust port, which is applied in the direction of lifting valve, valve detail, valve device, etc., and can solve problems such as leakage and poor sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

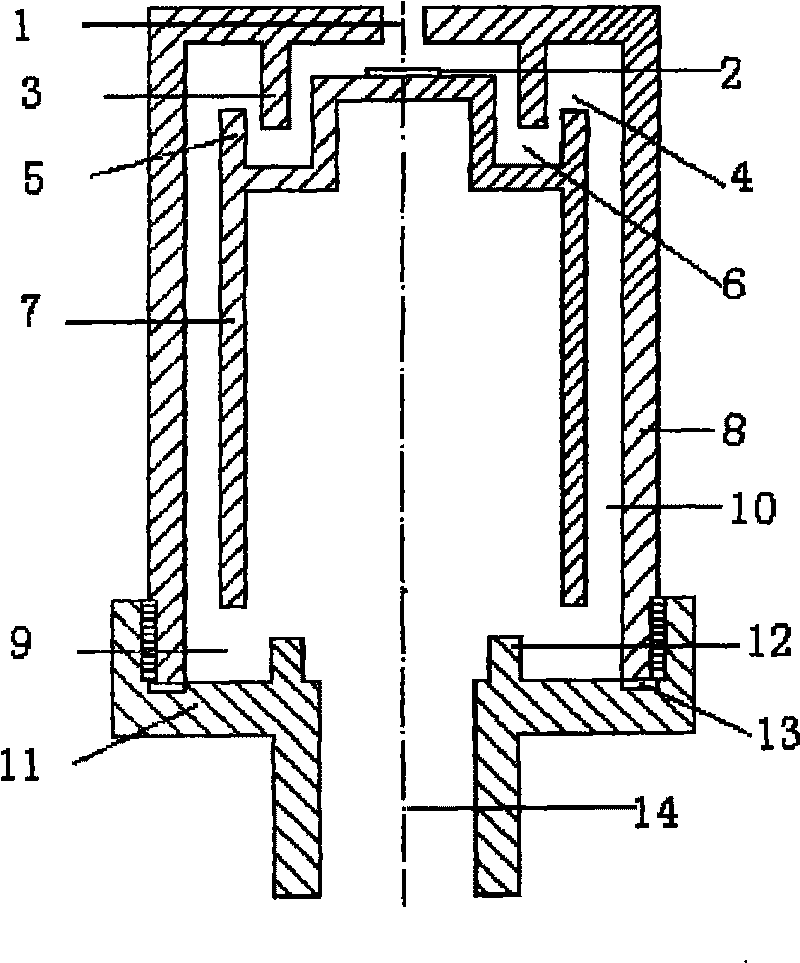

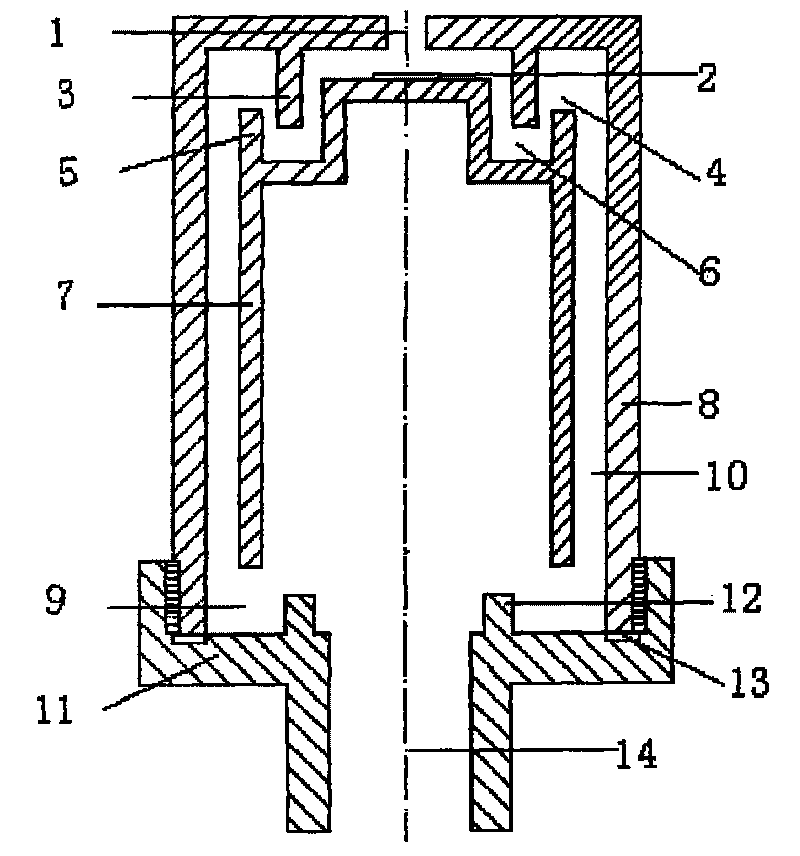

[0005] As shown in the figure, the non-leakage reversible automatic exhaust valve includes a valve cover (8) with a valve cover retaining ring (3) provided with an exhaust port (1), and a valve seat retaining ring (12) and a valve seat liquid tank (9 ) valve seat (11), the two are connected by threads to form the inner cavity (10) of the valve body, and a sealing ring (13) is arranged at the joint of the two bodies, and there is a buoy retaining ring (5) and a buoy liquid tank (6) in the valve The top is provided with the buoy (5) of the gasket (2), and the valve seat (11) is provided with an air inlet (14). Between the inner cavity (10) of the cover and the exhaust port (1), when the air discharge liquid level reaches the bottom of the buoy (7), a liquid seal is formed at the bottom of the buoy (7) to generate buoyancy and rise accordingly, and the buoy (7) The top gasket (2) closes the exhaust port (1). When the pressure increases and the gasket (2) cannot seal the exhaust p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com