Vacuum adsorber

A technology of vacuum adsorption and adsorption surface, applied in the field of engraving machines, can solve the problems of clogging adsorption pipes, influence of workpiece engraving quality, vacuum pump failure, etc., and achieve the effect of good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

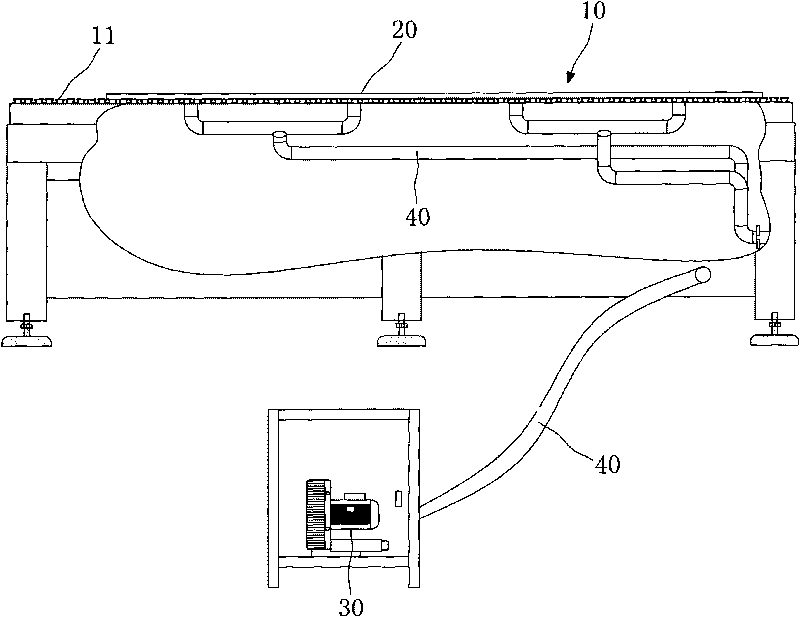

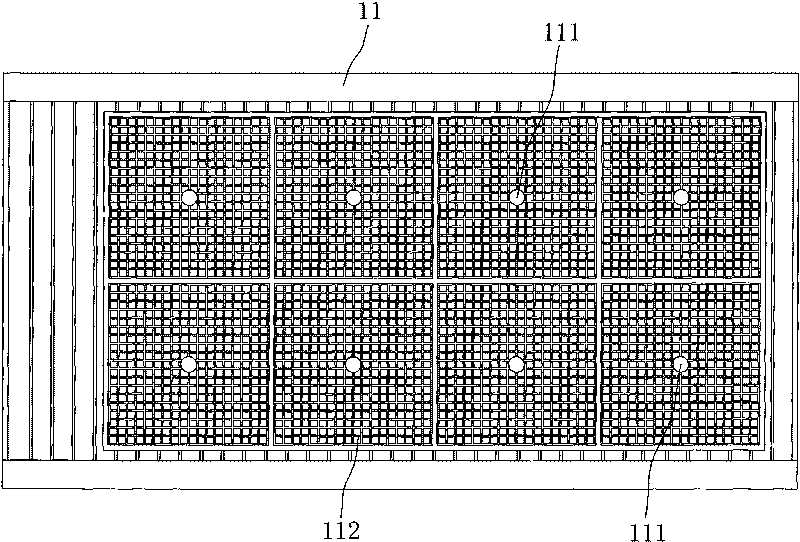

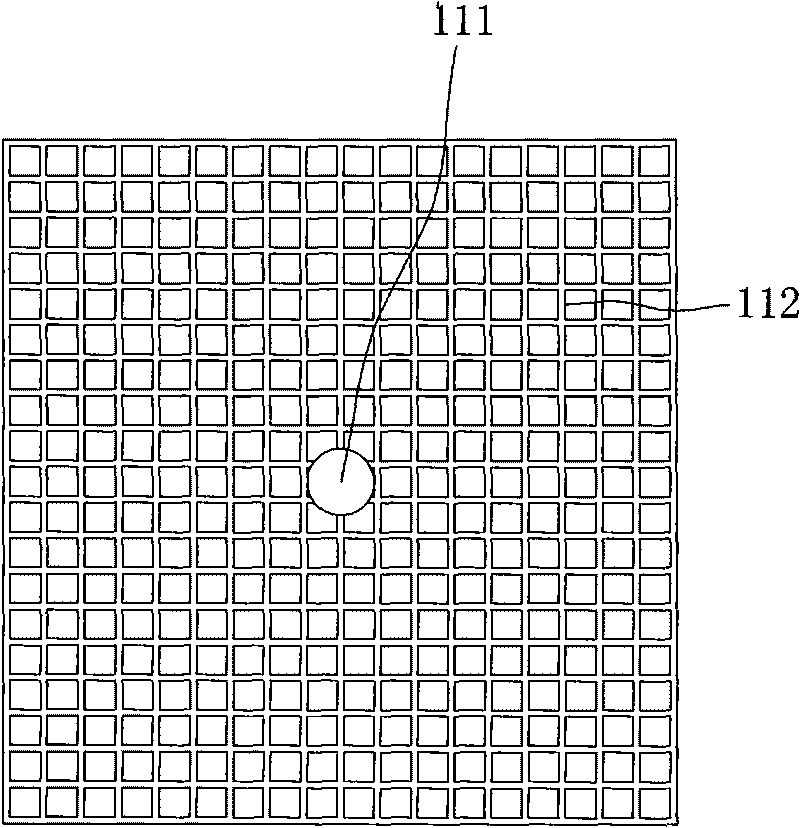

[0009] like figure 1 , 2 As shown, a vacuum adsorption device includes a workbench 10 with an adsorption surface 11 on the upper side, and a breathable plate 20 is laid on the adsorption surface 11 of the workbench 10 .

[0010] The setting of the air-permeable plate 20 not only realizes the adsorption and fixation of the workpiece, but also prevents debris from entering the adsorption holes on the lower side of the air-permeable plate 20, that is, the air-permeable plate 20 ensures the stable operation of the vacuum pump 30 and ensures the smooth progress of the engraving process .

[0011] As a preferred solution of the present invention, the air-permeable board 20 is a medium density board or a low density board.

[0012] Further, the density of the density board is 360~880kg / m 3 .

[0013] Further, the density of the density board is 360~550kg / m 3 , that is, the air-permeable board 20 is a low-density board. At this time, the air-permeable board 20 has low density, li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com