Processing die of brush body of pressurized water-saving cleaning brush

A technology for processing molds and brush bodies, which is applied in the field of processing molds for cleaning brush bodies, can solve the problems of affecting product quality, high labor intensity, troublesome operation, etc., and achieve the effects of improving pass rate, reducing labor intensity, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

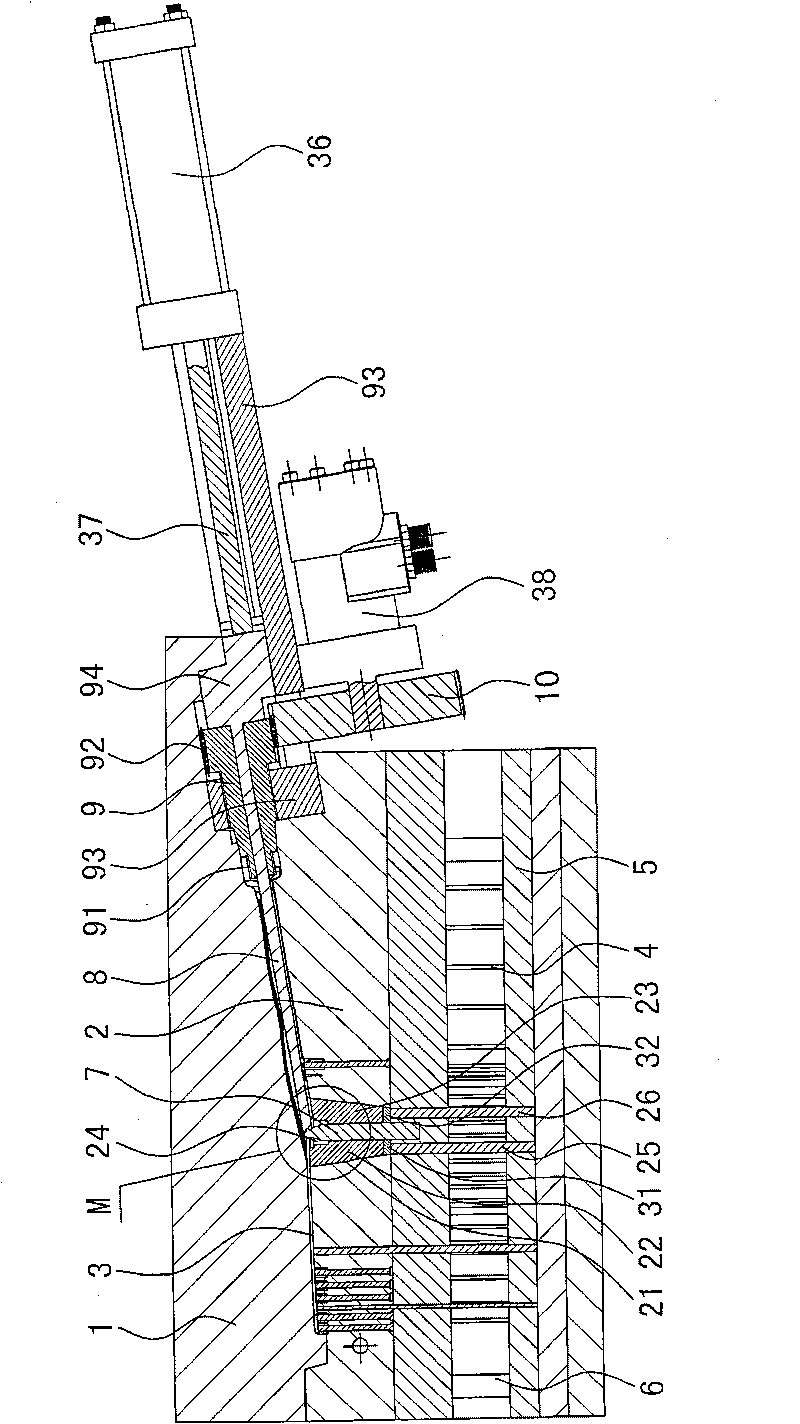

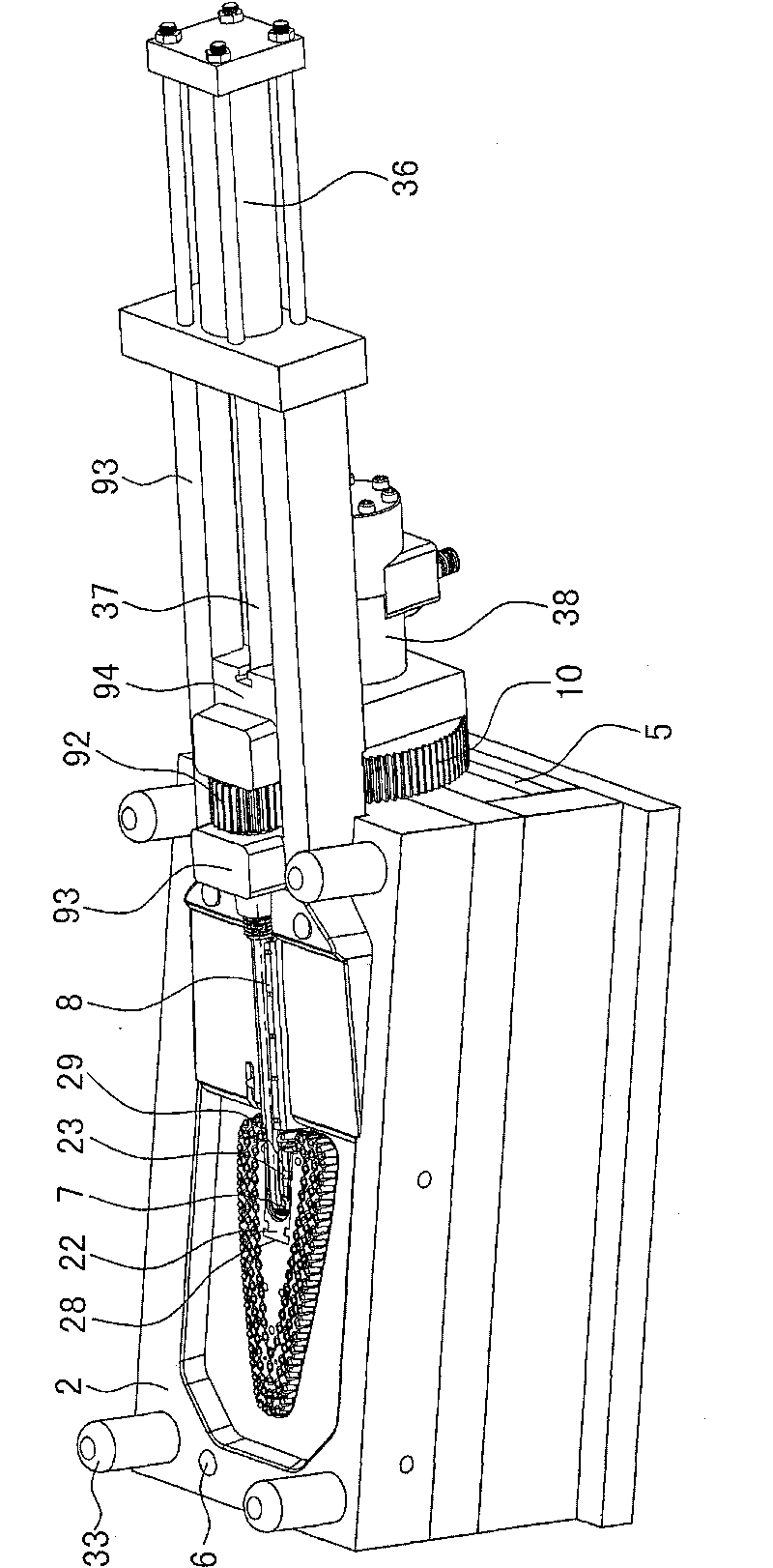

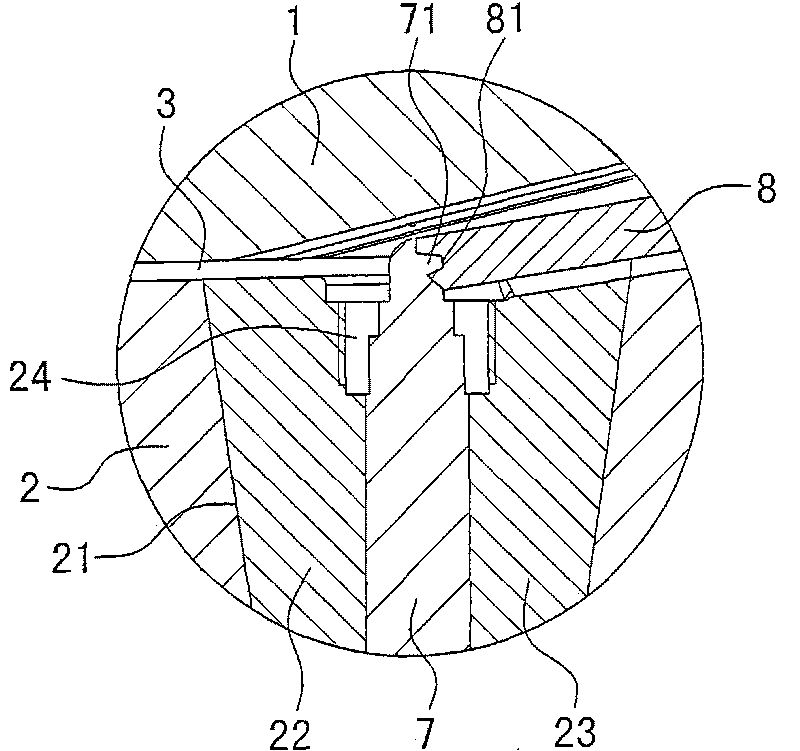

[0013] The invention discloses a processing mold for a pressurized water-saving cleaning brush body, such as Figure 6 As shown, the brush body 12 of the pressurized water-saving cleaning brush is made into one with the handle 11, and the middle part of the brush body 12 is shaped on a longitudinal water outlet hole 15, and the longitudinal water outlet hole 15 communicates with the horizontal water inlet hole 14 of the handle, and the longitudinal water outlet hole 15 The mouth of the hollow stud 16 is shaped on, and the mouth of the hollow stud 16 installs the nozzle 19 through the nut 18, and the brush body bottom surface installs the bristles 13, as Figure 1-Figure 5As shown, the processing mold of the brush body includes a cavity 1 installed on the movable template and a core 2 installed on the fixed template. The cavity 1 and the core 2 constitute the cavity 3 of the brush body. The cavity 1 and the core 2. Positioned by the guide post 33, the mold cavity is driven by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com