High wear-resistence self-lubricating polyformaldehyde compound and preparation method thereof

A polyoxymethylene compound, self-lubricating technology, applied in the field of polymer materials and their molding processing, can solve the problems of material rigidity, toughness and heat resistance reduction, and achieve stable product quality, improved heat resistance, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

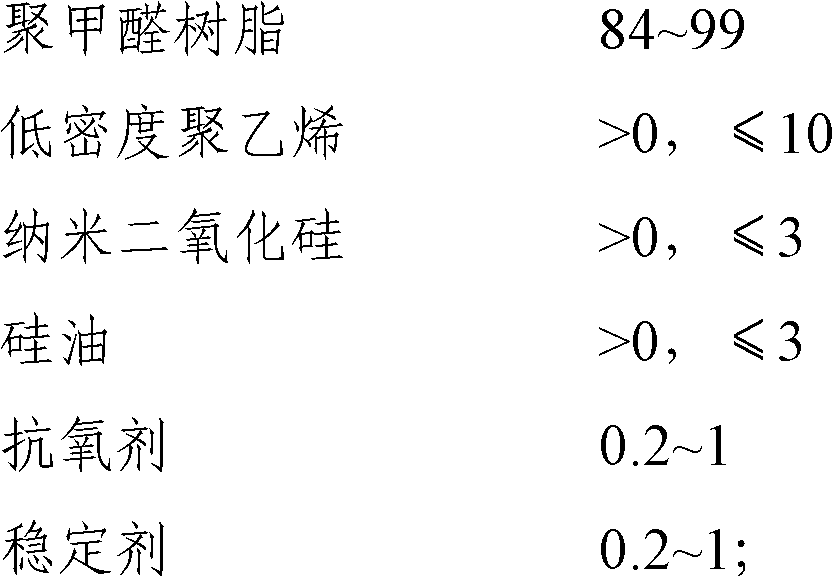

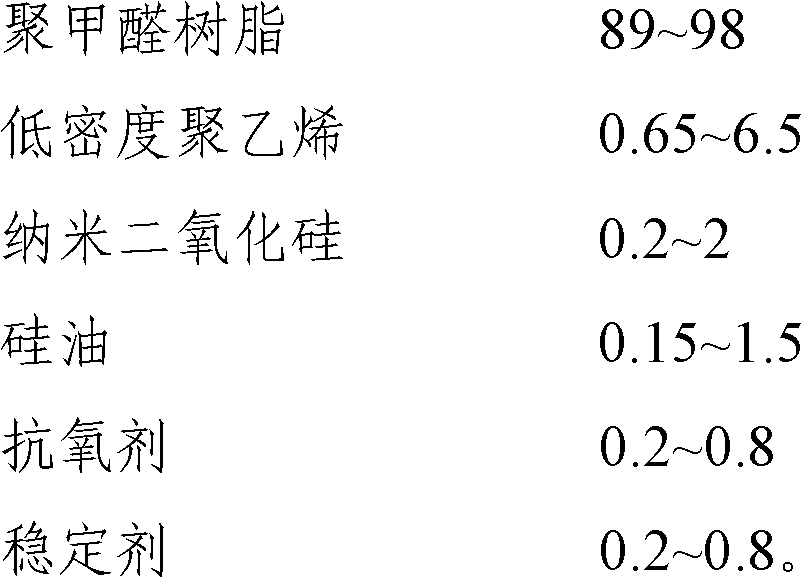

Method used

Image

Examples

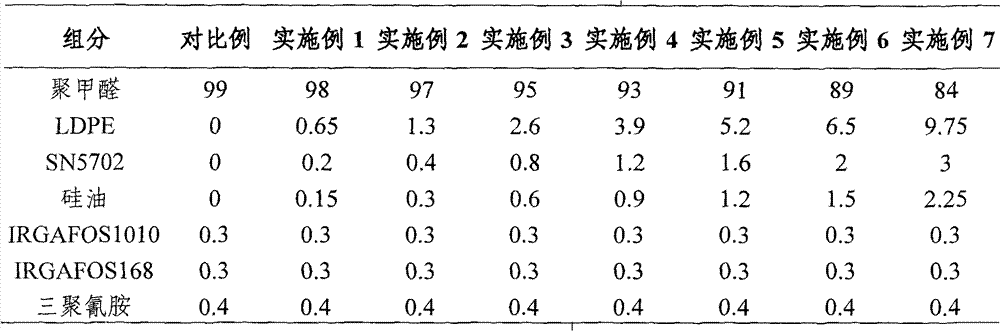

Embodiment 1

[0037] According to POM 98 mass %, LDPE 0.65 mass %, SN57020.2 mass %, silicone oil 0.15 mass %, IRGANOX10100.3 mass %, IRGAFOS1680.3 mass %, melamine 0.4 mass %, the raw materials were weighed and mixed uniformly in a high-speed mixer, Put into a twin-screw extruder to extrude and granulate. The processing temperature setting is 150°C for the first stage, 170°C for the second stage, 175°C for the third stage, 175°C for the fourth stage, 175°C for the fifth stage, 175°C for the sixth stage, 175°C for the seventh stage, and 175°C for the eighth stage ℃, the ninth section is 175℃, the die head temperature is 170℃; the strands are watered and pelletized.

Embodiment 2

[0039] According to POM 97 mass %, LDPE 1.3 mass %, SN57020.4 mass %, silicone oil 0.3 mass %, IRGANOX10100.3 mass %, IRGAFOS1680.3 mass %, melamine 0.4 mass %, the raw materials were weighed and mixed uniformly in a high-speed mixer, Put into a twin-screw extruder to extrude and granulate. The processing temperature setting is 150°C for the first stage, 170°C for the second stage, 175°C for the third stage, 175°C for the fourth stage, 175°C for the fifth stage, 175°C for the sixth stage, 175°C for the seventh stage, and 175°C for the eighth stage ℃, the ninth section is 175℃, the die head temperature is 170℃; the strands are watered and pelletized.

Embodiment 3

[0041] According to POM 95% by mass, LDPE 2.6% by mass, SN57020.8% by mass, silicone oil 0.6% by mass, IRGANOX10100.3% by mass, IRGAFOS1680.3% by mass, 0.4% by mass of melamine, the raw materials were weighed and mixed uniformly in a high-speed mixer, Put into a twin-screw extruder to extrude and granulate. The processing temperature setting is 150°C for the first stage, 170°C for the second stage, 175°C for the third stage, 175°C for the fourth stage, 175°C for the fifth stage, 175°C for the sixth stage, 175°C for the seventh stage, and 175°C for the eighth stage ℃, the ninth section is 175℃, the die head temperature is 170℃; the strands are watered and pelletized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com