Good-heat-conduction heavy-load precise displacement adjusting frame for laser processing head

A laser processing head, precision displacement technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of limiting the power used by the optical system, affecting the reliability of the optical system, etc., to achieve rich adjustment directions, light weight, Small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

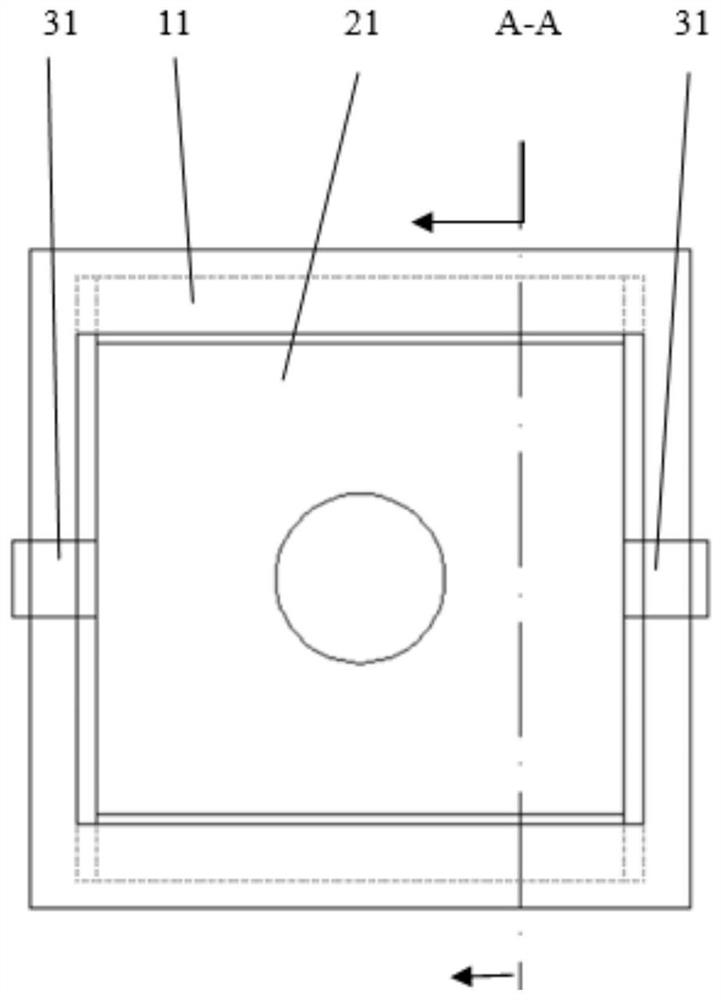

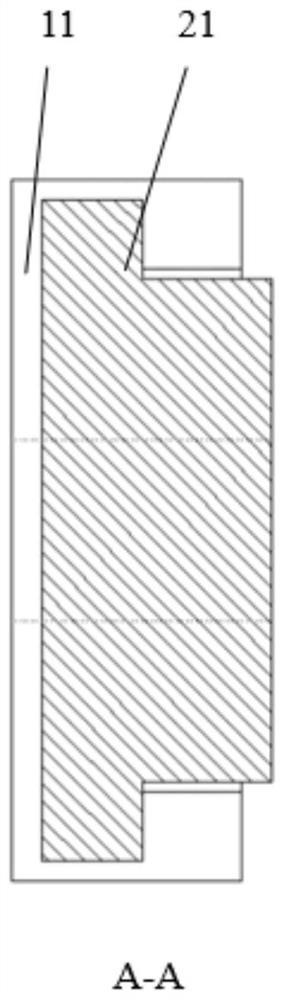

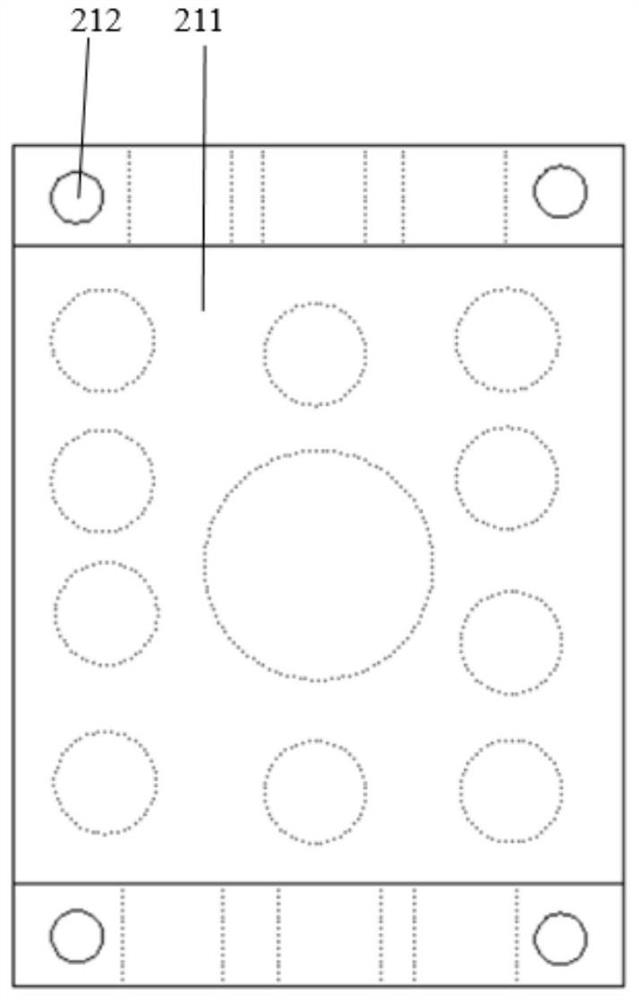

[0031] The fine heat conduction and large load precision displacement adjustment mount for laser processing heads proposed by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] The good heat conduction and large load precision displacement adjustment frame for laser processing heads proposed by the present invention includes a base, a slider and a drag mechanism, and the slider and the drag mechanism are arranged on the base, wherein the A self-lubricating structure is provided between the base and the slider, and the drag mechanism drags the slider to move relative to the base to form a one-dimensional adjustment frame. It uses sliding friction to realize the relative movement between the slider and the base, and it is important that at least one of the contact surfaces between the base and the slider has a self-lubricating structure, which greatly reduces the sliding friction.

[0033] Usua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com