Corrugated steel web reinforced concrete tunnel and underground structural unit

A corrugated steel web and reinforced concrete technology, which is applied to underwater structures, tunnels, tunnel linings, etc., can solve problems such as poor waterproof effect, large construction volume, and reduced rigidity of arched tunnels, so as to achieve convenient installation and reduce construction costs. The effect of less water, links and hidden dangers of water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

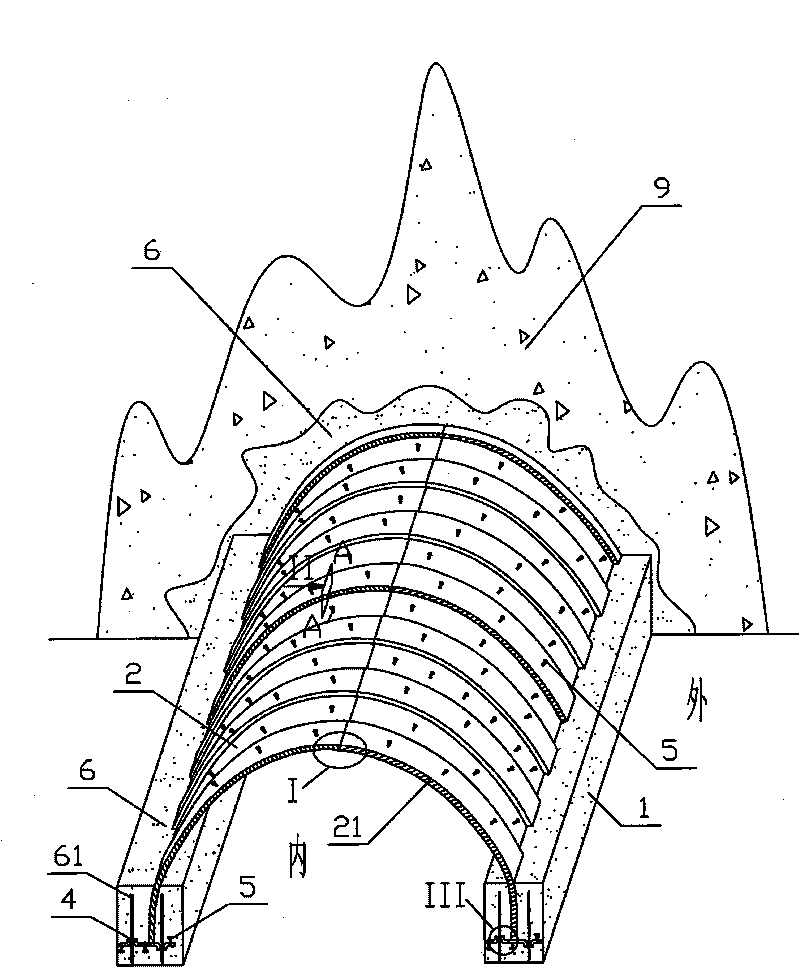

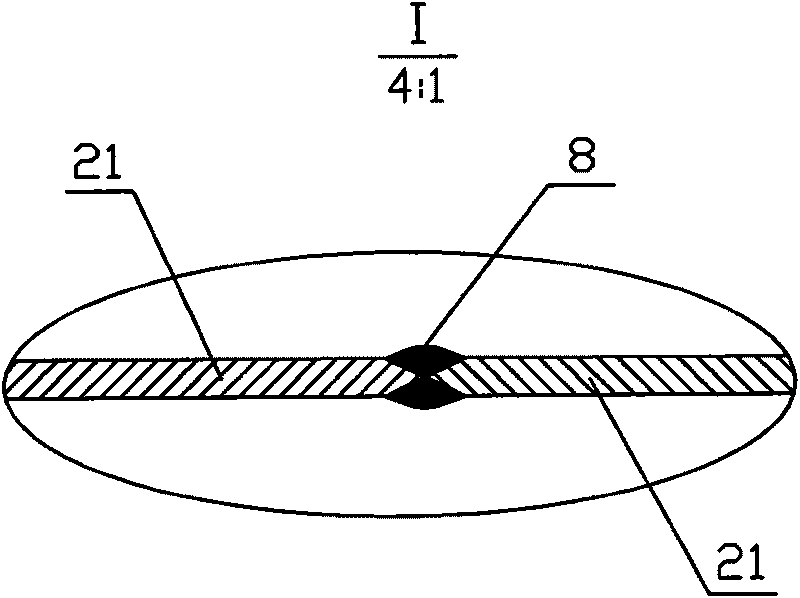

[0026] Corrugated steel web reinforced concrete tunnels and underground structural units, such as figure 1 , 3 , 4, 7, and 8, comprising a reinforced reinforced concrete base 1, a corrugated steel web beam arch unit 2 arranged on the reinforced reinforced concrete base 1, and the corrugated steel web beam arch unit 2 is arched The corrugated steel web beam arch unit 2 is composed of one or two arc-shaped corrugated steel webs 21, and the adjacent corrugated steel web beam arch units 2 are connected by a waterproof connection device 3, and the corrugated steel webs 21 A steel plate 4 is connected to the end connected with the reinforced concrete base 1, and a stud 5 is welded on the steel plate 4. The corrugated steel web beam arch unit is arched, so under the premise of meeting a certain structural strength, the use of corrugated steel webs saves a lot of building materials compared with ordinary steel plates. At the same time, the connected parts are connected by waterproof ...

Embodiment 2

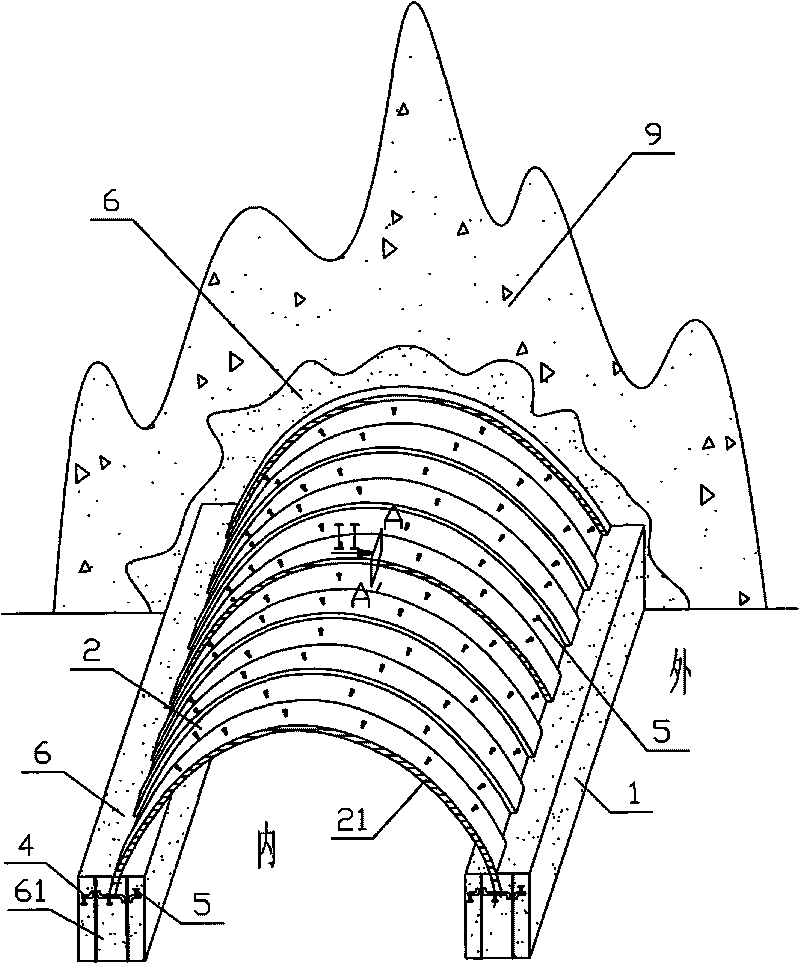

[0032] Corrugated steel web reinforced concrete tunnels and underground structural units, such as figure 2 , 6 , 7 and 8, comprising a reinforced reinforced concrete base 1, a corrugated steel web beam arch unit 2 arranged on the reinforced reinforced concrete base 1, the corrugated steel web beam arch unit 2 is arched, corrugated The steel web beam-arch unit 2 is composed of one or two arc-shaped corrugated steel webs 21, and the adjacent corrugated steel web beam-arch units 2 are connected by a waterproof connection device 3, and the corrugated steel webs 21 and steel bars A steel plate 4 is connected to the connected end of the concrete base 1, and a stud 5 is welded on the steel plate 4. The corrugated steel web beam arch unit is arched, so under the premise of meeting a certain structural strength, the use of corrugated steel webs saves a lot of building materials compared with ordinary steel plates. At the same time, the connected parts are connected by waterproof conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com