Central shaft of continuously variable transmission of snowmobile

A technology of continuously variable transmission and central shaft, applied in the direction of shafts, shafts and bearings, portable lifting devices, etc., can solve problems affecting the working performance of the engine and continuously variable transmission, poor coaxiality of the central shaft, and unstable power transmission, etc., to achieve weakening Small, small pitch, smooth running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

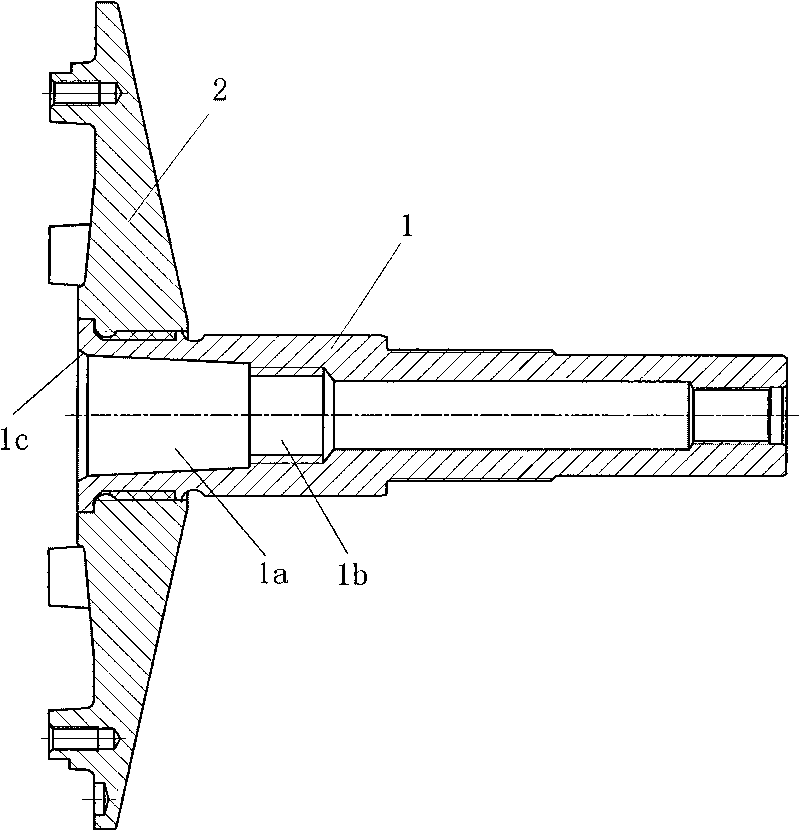

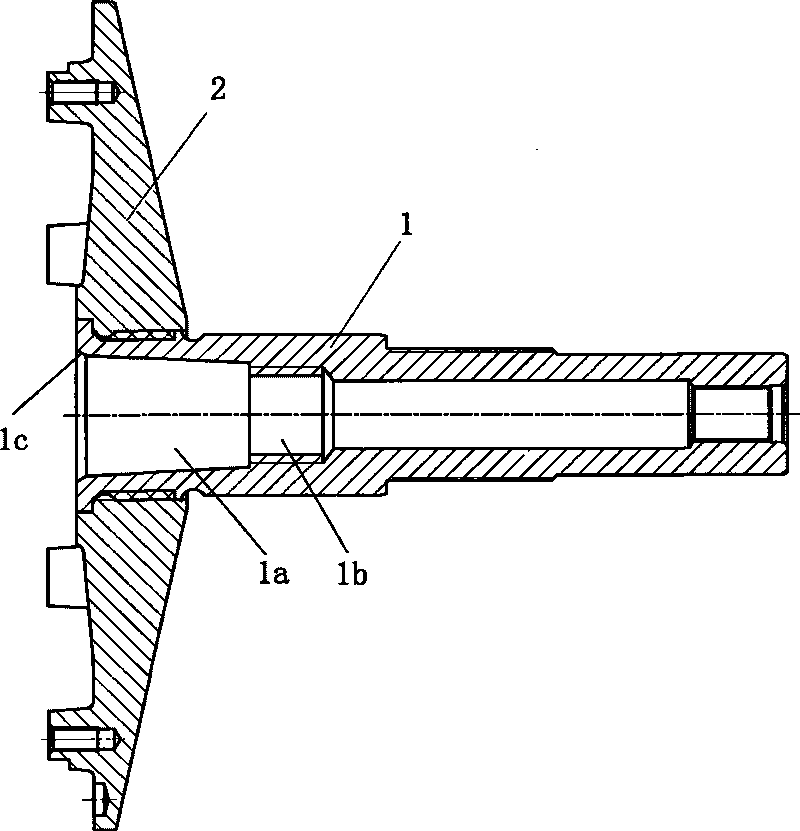

[0011] Such as figure 1 As shown, the present invention is a central shaft of a continuously variable transmission for a snowmobile. A fixed plate 2 is fixed at one end of the central shaft 1. The central shaft 1 is a hollow shaft provided with an axis through hole, and an engine output shaft is provided along its axis. Mounting hole, the mounting hole of the engine output shaft is composed of a taper hole 1a and a threaded hole 1b that are connected, the length of the taper hole 1a is about twice the length of the threaded hole 1b, and the large end of the taper hole 1a is fitted with a fixed shaft 1. The end faces of the disc ends are connected. For the convenience of assembly, a chamfer 1c is provided at the large end of the taper hole 1a. The thread direction of the threaded hole 1b is opposite to that of the central axis 1, and the thread fit will not lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com