Exhaust gas and hot-blast air dual-medium powder feeding system

A technology for hot air and powder feeding, applied in the field of coal-fired boilers, can solve problems such as poor mixing effect of spent gas and hot air, explosion accidents, etc., and achieve the effects of preventing slagging, tempering and burning, small transformation workload, and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

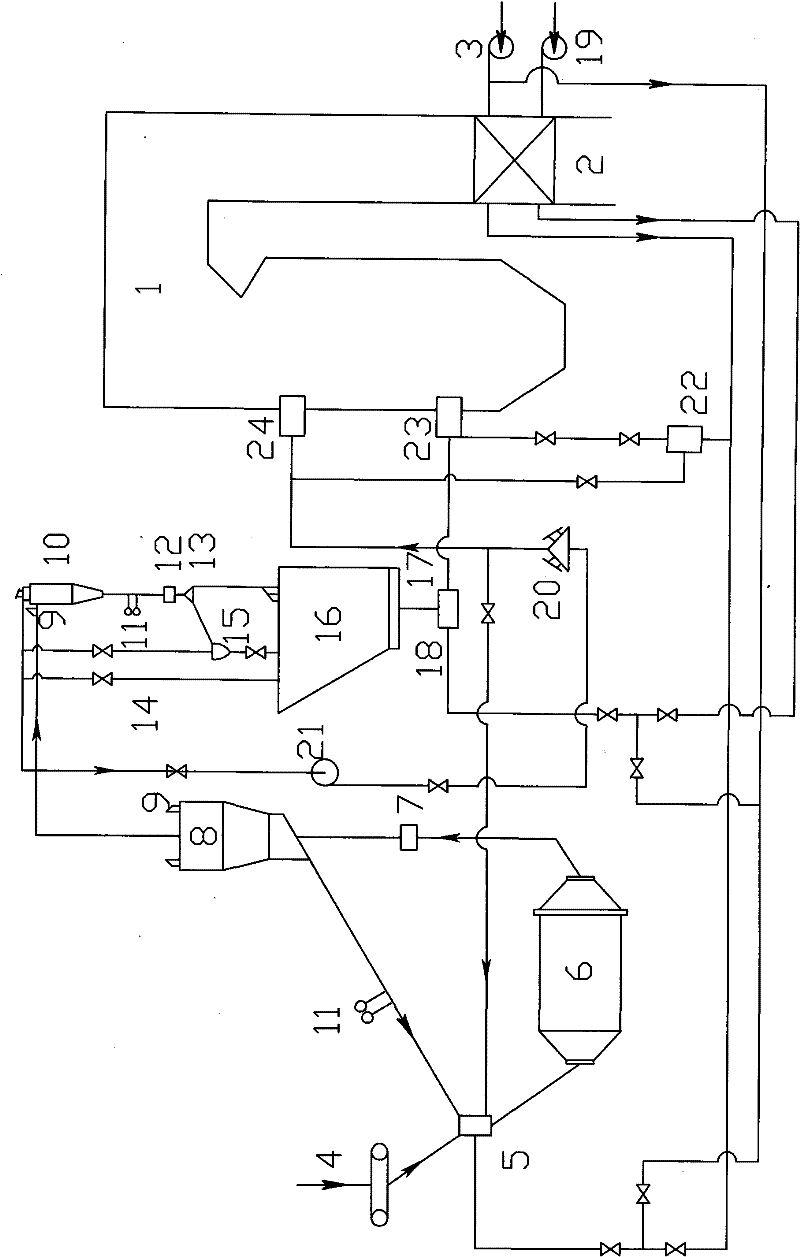

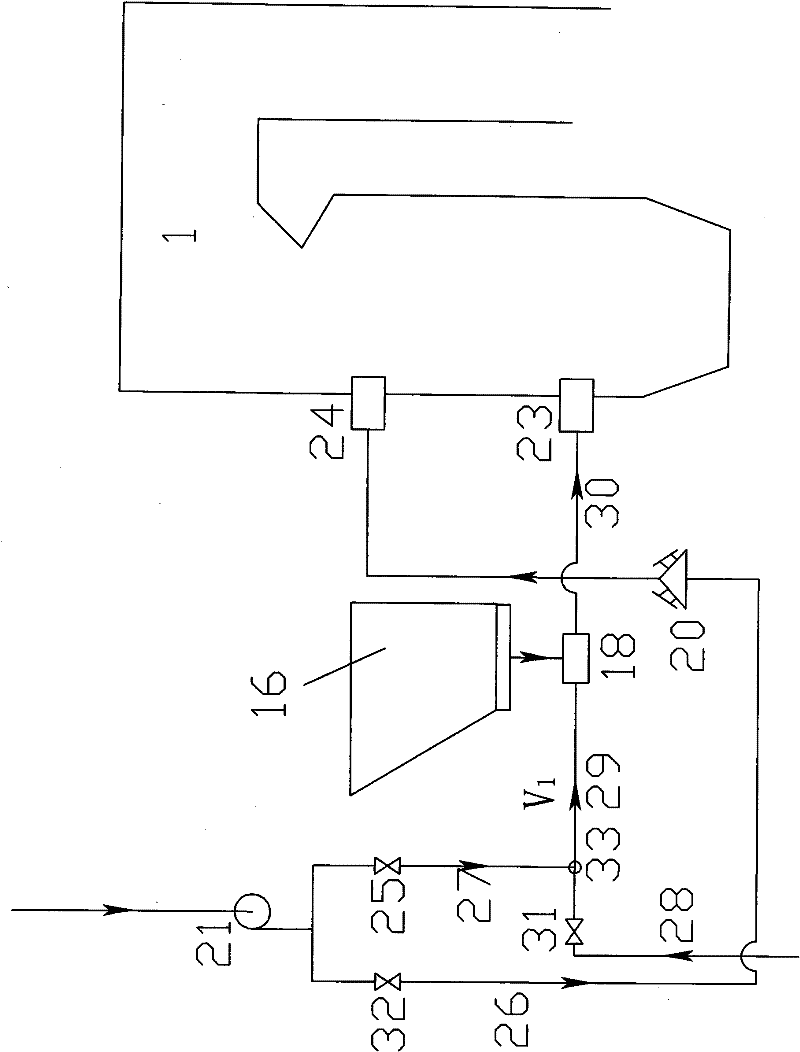

[0017] Specific implementation mode one: see Figure 2-5 , The exhaust gas and hot air dual-medium powder feeding system described in this embodiment includes a powder discharger 21, a tertiary air pipeline 26, a tertiary air pipeline control valve 32, an air powder mixer 18, a exhaust air bellows 20, a hot air pipeline 28, a primary Air pipeline 29, primary air pipeline control valve 31 and primary air powder delivery pipeline 30, described powder delivery system also includes exhaust pipeline fast shut-off valve 25, exhaust pipeline 27 and exhaust gas hot-air mixer 33, described tertiary air The inlet end of the pipeline 26, the inlet end of the exhaust gas pipeline 27 are all connected with the output end of the powder discharger 21, the outlet end of the tertiary air pipeline 26 is connected with the tertiary air nozzle 24 on the boiler 1, and the tertiary air pipeline 26 is provided with exhaust Air wind box 20; the outlet end of the hot blast pipeline 28 communicates wit...

specific Embodiment approach 2

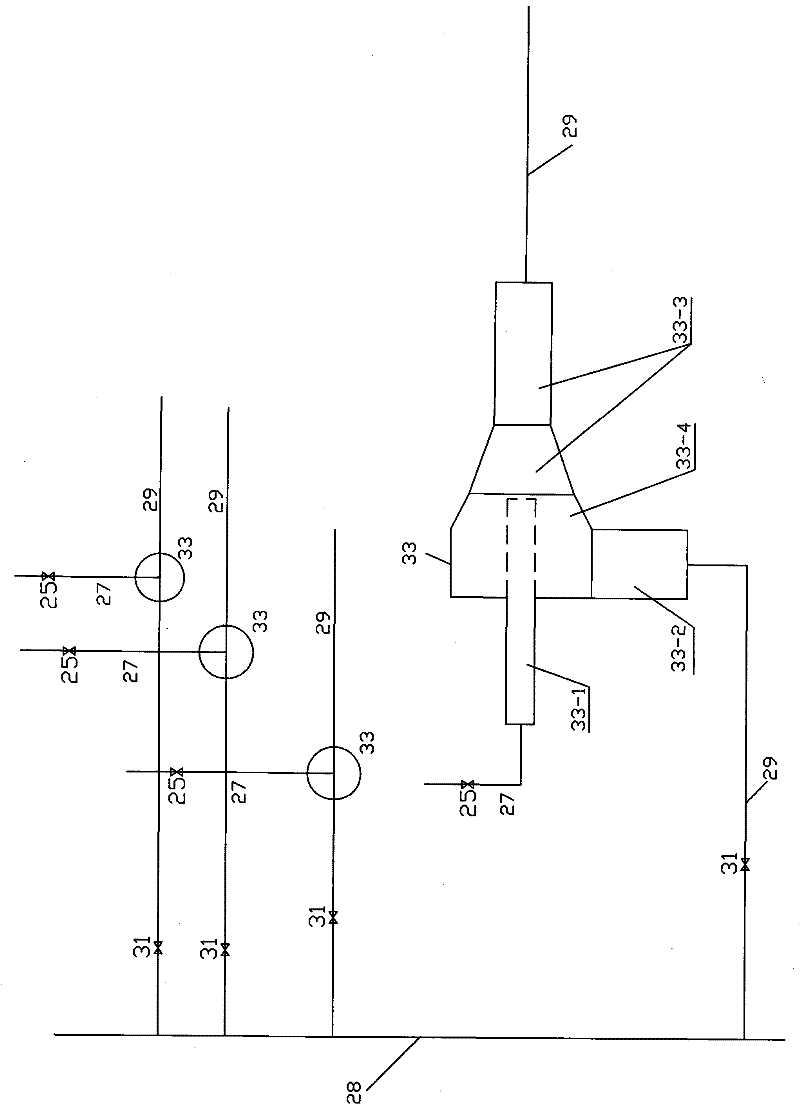

[0019] Specific implementation mode two: see Figure 3-5 , the exhaust air hot air mixer 33 in this embodiment is composed of an exhaust air nozzle 33-1, a hot air pipe 33-2, a mixing pipe 33-3 and a closed hot air receiving chamber 33-4, and the exhaust air nozzle 33-1 One end of the mixing tube 33-3 is inserted into the airtight hot blast receiving chamber 33-4, the mixing tube 33-3 is coaxially arranged opposite to the exhaust nozzle 33-1 and one end of the mixing tube 33-3 communicates with the airtight hot blast receiving room 33-4, and the hot blast tube One end of 33-2 communicates with the airtight hot air receiving chamber 33-4. The other end of the exhaust air nozzle 33-1 communicates with the exhaust air pipeline 27, and the other end of the mixing tube 33-3 and the other end of the hot air pipe 33-2 communicate with the primary air pipeline 29. The design of the exhaust air hot blast mixer 33 adopts the ejector principle. The exhaust air ejected from the exhaust ...

Embodiment 1

[0021] Example 1: The boiler has two layers of primary air burners and is equipped with two sets of pulverizing systems. Each system includes raw coal bunkers, coal feeders, coal mills, coarse powder separators, fine powder separators, powder exhausters and various pipelines. Both sets of milling systems are in normal operation. combined with figure 2This embodiment will be described. The dual-medium powder feeding system of exhaust air and hot air includes a control valve 25 , an exhaust air pipeline 27 , a hot air pipeline 28 , a primary air pipeline 29 , and a primary air powder supply pipeline 30 . Close the original tertiary air control valve, open the control valve of the exhaust air pipeline, supply the exhaust air at the outlet of the powder discharger into the primary air pipeline, and adjust the hot air control valve of the primary air pipeline according to the primary wind speed to achieve the mixture of exhaust air and hot air The purpose of sharing fans. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com