Backlight module of displayer

A backlight module and display technology, applied in optics, instruments, optical components, etc., can solve problems such as weight increase and cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

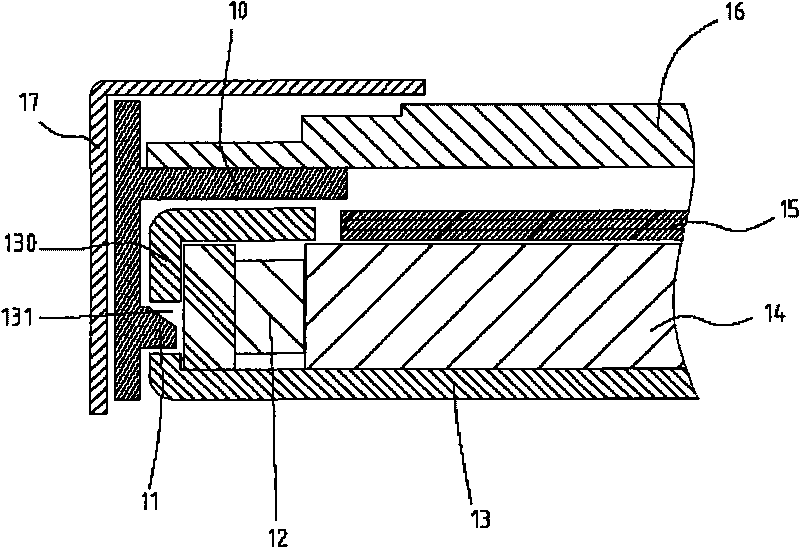

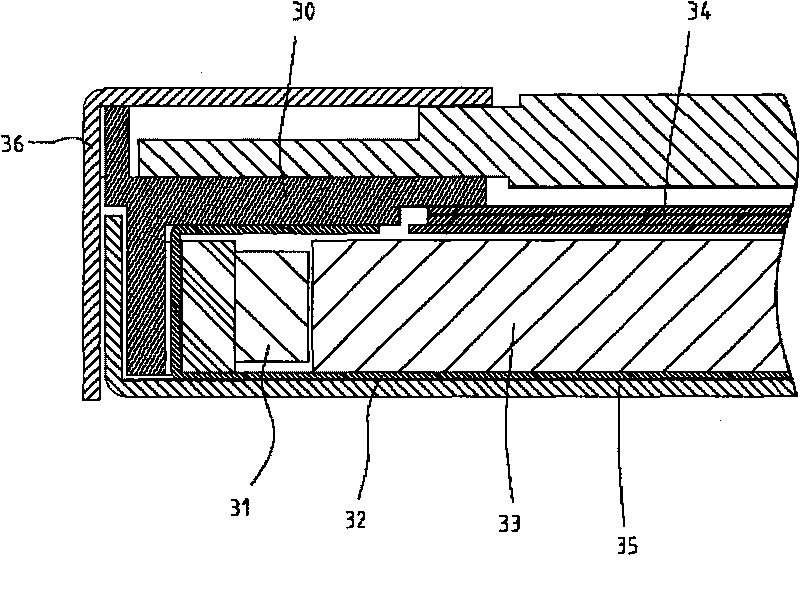

[0040] The backlight module of the present invention mainly includes:

[0041] A frame body, which is a frame-shaped structure, has a vertical portion and a horizontal portion, and has a concave portion (or convex portion) in the vertical portion;

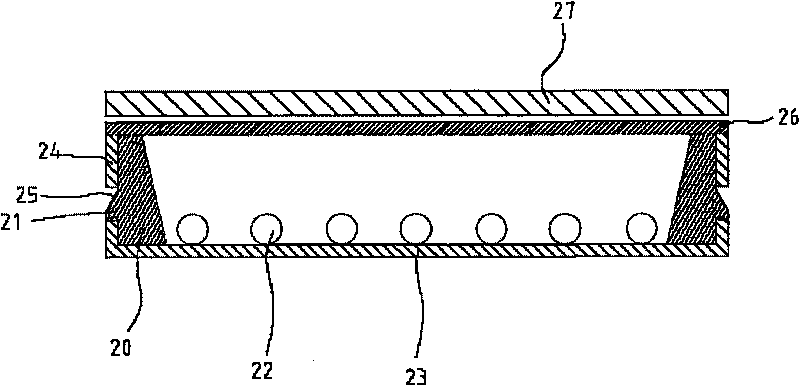

[0042] a light source is arranged inside the frame;

[0043] A reflection sheet is arranged on the lower side of the light source, has a vertical portion and a horizontal portion, and has a convex portion (or concave portion) on the vertical portion, and the convex portion and the concave portion are combined to fix the reflection sheet.

[0044] The above-mentioned concave part can be a fitting hole or a fitting groove, and the above-mentioned convex part is a fitting block corresponding to the concave part or any edge of the reflecting sheet.

[0045] The above-mentioned light source may be a direct-type light source or an edge-type light source.

[0046] In order to better understand the implementation forms of the present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com