Heat radiation assembly fastener and heat radiation device

A technology for heat dissipation components and heat dissipation devices, which is applied to electrical components, electric solid state devices, semiconductor devices, etc., and can solve the problems of large inventory and troublesome materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

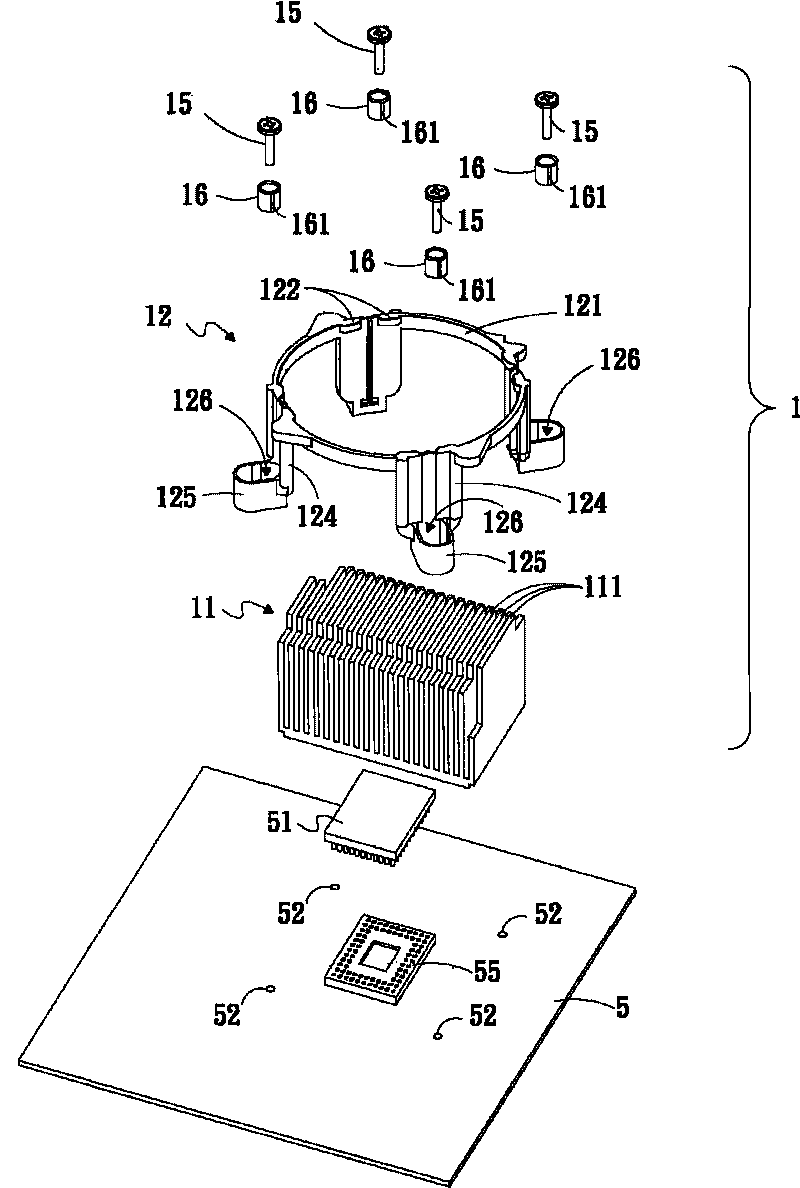

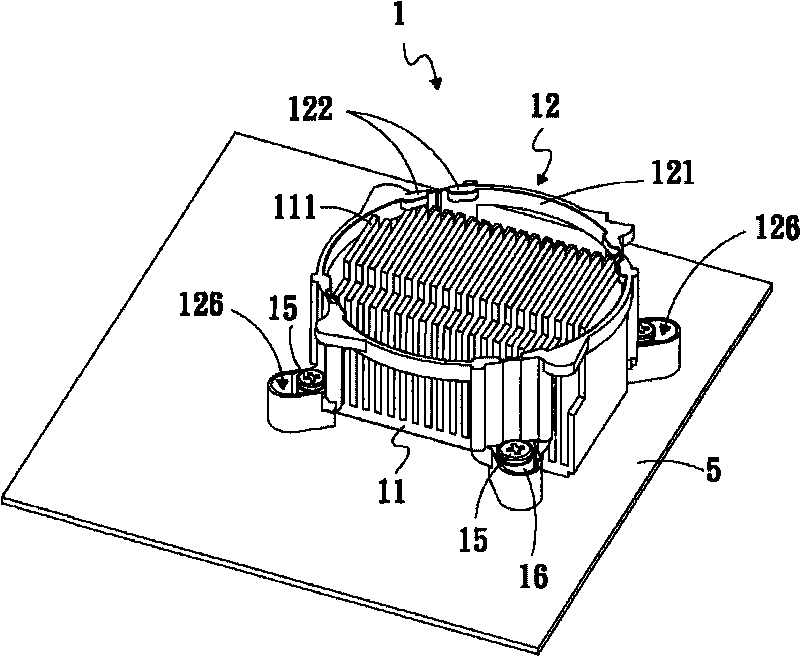

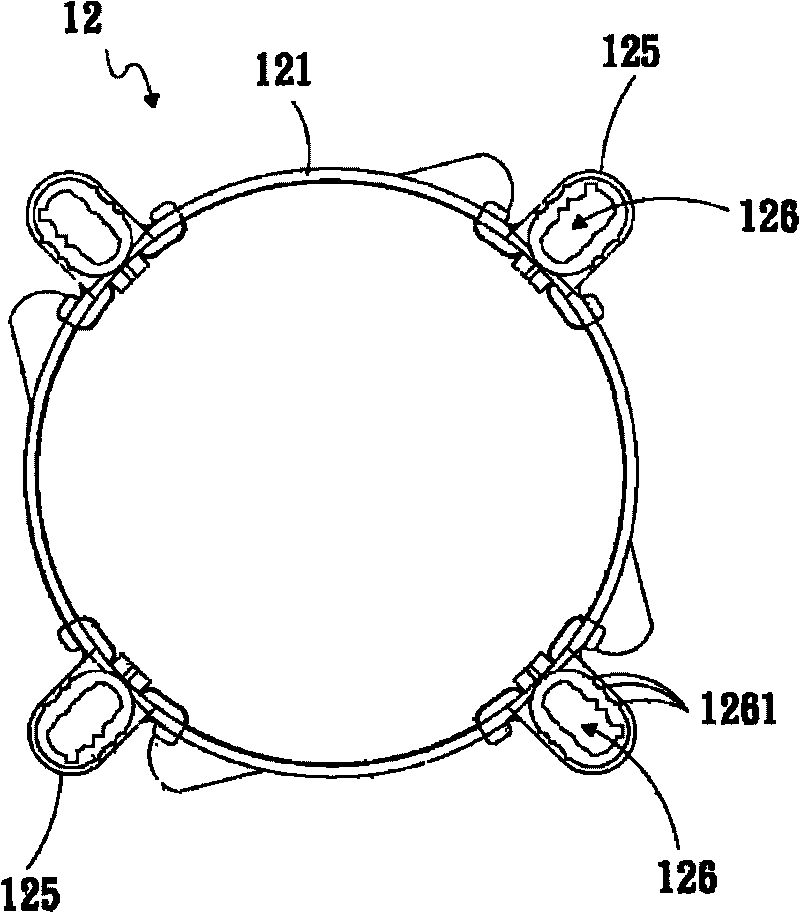

[0022] see Figure 1 to Figure 6B As shown, it is the heat dissipation device disclosed in the first embodiment of the present invention. The heat dissipation device 1 is arranged on a circuit board 5 with electronic components 51. The circuit board 5 is provided with a plurality of through holes 52 on the side where the electronic components 51 are disposed. Here, the electronic component 51 can be a central processing unit (CPU), but it is not limited thereto. The present invention can also be arranged on other electronic components that generate heat to provide heat dissipation. In addition, the electronic component 51 can be pre-welded on the circuit board 5 , or mounted on the base (Socket) 55 of the circuit board 5 . The heat dissipation device 1 includes a heat dissipation component 11 , a fastener 12 for the heat dissipation component, a plurality of locking components 15 , and a plurality of positioning kits 16 .

[0023] The heat dissipation component 11 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com