A kind of synthetic food machinery lubricating oil and preparation method thereof

A technology for food machinery and lubricating oil, applied in the field of lubricating oil, can solve the problems of no uniform food-grade lubricating oil, and achieve the effects of outstanding thermal oxygen stability, good viscosity-temperature performance, and reasonable components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

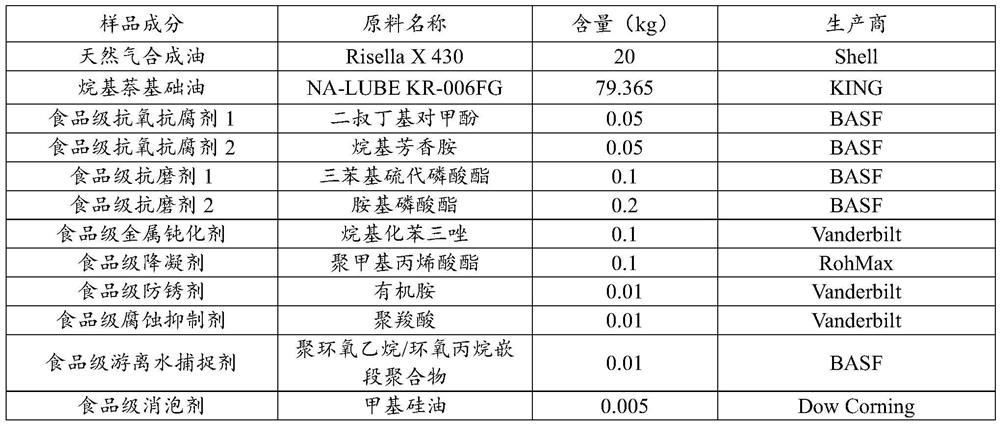

Embodiment 1

[0029] Embodiment 1: the preparation method of a kind of synthetic food machinery lubricating oil in the present embodiment is:

[0030] First, add natural gas synthetic oil and alkylnaphthalene base oil with a total formula of 45-55wt% into the blending kettle, start stirring, the stirring temperature is 50°C±2°C, and the stirring speed is 100±10r / min. Keeping the temperature and stirring speed, add food-grade antioxidant, food-grade anti-wear agent, food-grade metal passivator, food-grade pour point depressant, food-grade rust inhibitor, food-grade corrosion inhibitor and the rest in sequence. The natural gas synthetic oil and alkyl naphthalene base oil are obtained, continue to maintain the stirring temperature of 50 ℃ ± 2 ℃, and the stirring speed of 100 ± 10 r / min, and stir and reconcile for 1 to 2 hours. Then add food-grade free water scavenger and food-grade defoamer in sequence. Turn off the heat and cool to room temperature with stirring. The stirring time of the wh...

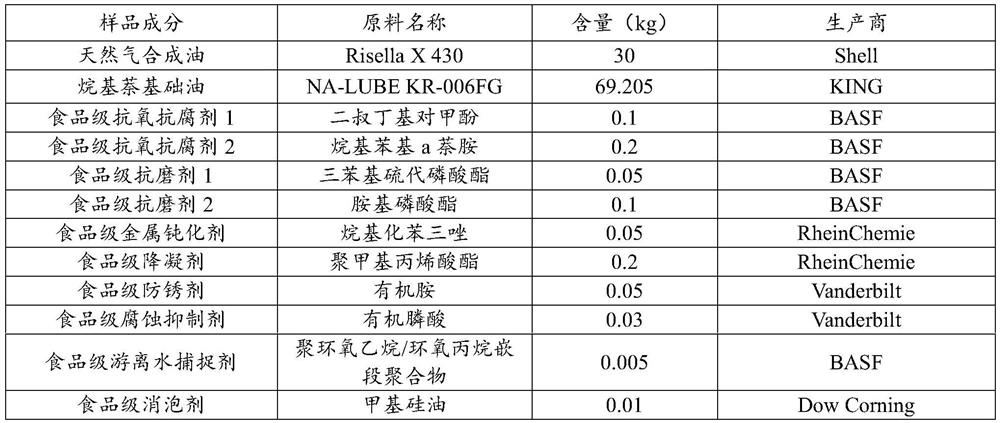

Embodiment 2

[0035] Sample composition raw material name Content (kg) manufacturer natural gas synthetic oil Risella X 430 70 Shell Alkyl Naphthalene Base Oil NA-LUBE KR-029FG 29.024 KING Food Grade Antioxidant Anticorrosion 1 Alkylarylamine 0.2 BASF Food Grade Antioxidant Anticorrosion 2 Alkylphenyl a naphthylamine 0.3 Vanderbil food grade antiwear agent Triphenyl phosphorothioate 0.01 BASF Food grade metal passivator Benzenetriazole Derivatives 0.01 Vanderbil food grade pour point depressant polymethacrylate 0.3 RohMax food grade rust inhibitor Heterocyclic compounds 0.1 LANXESS Food Grade Corrosion Inhibitor 1 polycarboxylic acid 0.03 LANXESS Food Grade Corrosion Inhibitor 2 Metal corrosion inhibitor 0.02 Vanderbilt Food grade free water scavenger Polymer polyether 0.001 BASF food grade defoamer Silicone Defoamer 0.005 Dow Corning

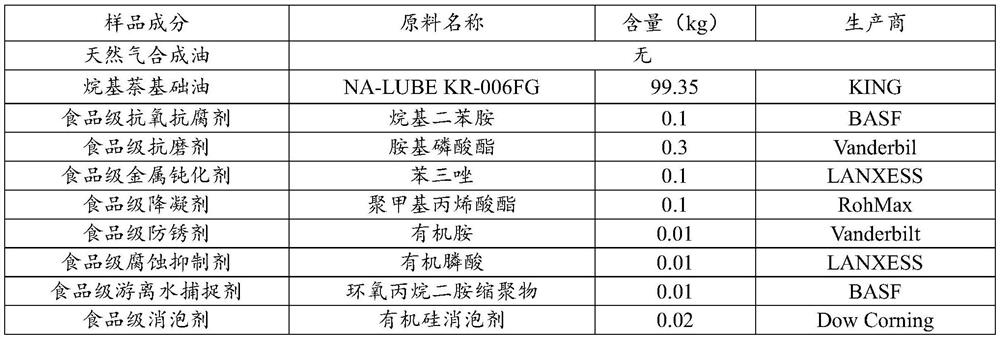

Embodiment 3

[0037] Sample composition raw material name Content (kg) manufacturer natural gas synthetic oil Risella X 430 39.21 Shell Alkyl Naphthalene Base Oil NA-LUBE KR-029FG 60 KING Food Grade Antioxidant Anticorrosion 1 Alkyl diphenylamine 0.1 BASF Food Grade Antioxidant Anticorrosion 2 Alkylarylamine 0.1 Vanderbil Food Grade Antioxidant Anticorrosion 3 Di-tert-butyl-p-cresol 0.1 BASF Food grade antiwear agent 1 Triphenyl phosphorothioate 0.06 Vanderbil Food grade antiwear agent 2 Alkyl Phosphate 0.04 Vanderbil Food Grade Metal Passivator 1 Substituted triazoles 0.03 LANXESS Food Grade Metal Passivator 2 benzotriazole 0.02 LANXESS food grade pour point depressant polymethacrylate 0.2 RohMax food grade rust inhibitor organic amine 0.05 BASF Food Grade Corrosion Inhibitor Metal corrosion inhibitor 0.03 Vanderbil Food grade free water scavenger 1 Pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com