Planetary mixer

A planetary mixer and mixing head technology, used in mixer accessories, mixers with rotary mixing devices, mixers, etc., can solve the problems of oil leakage, oil leakage economy, loss, etc., and achieve the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

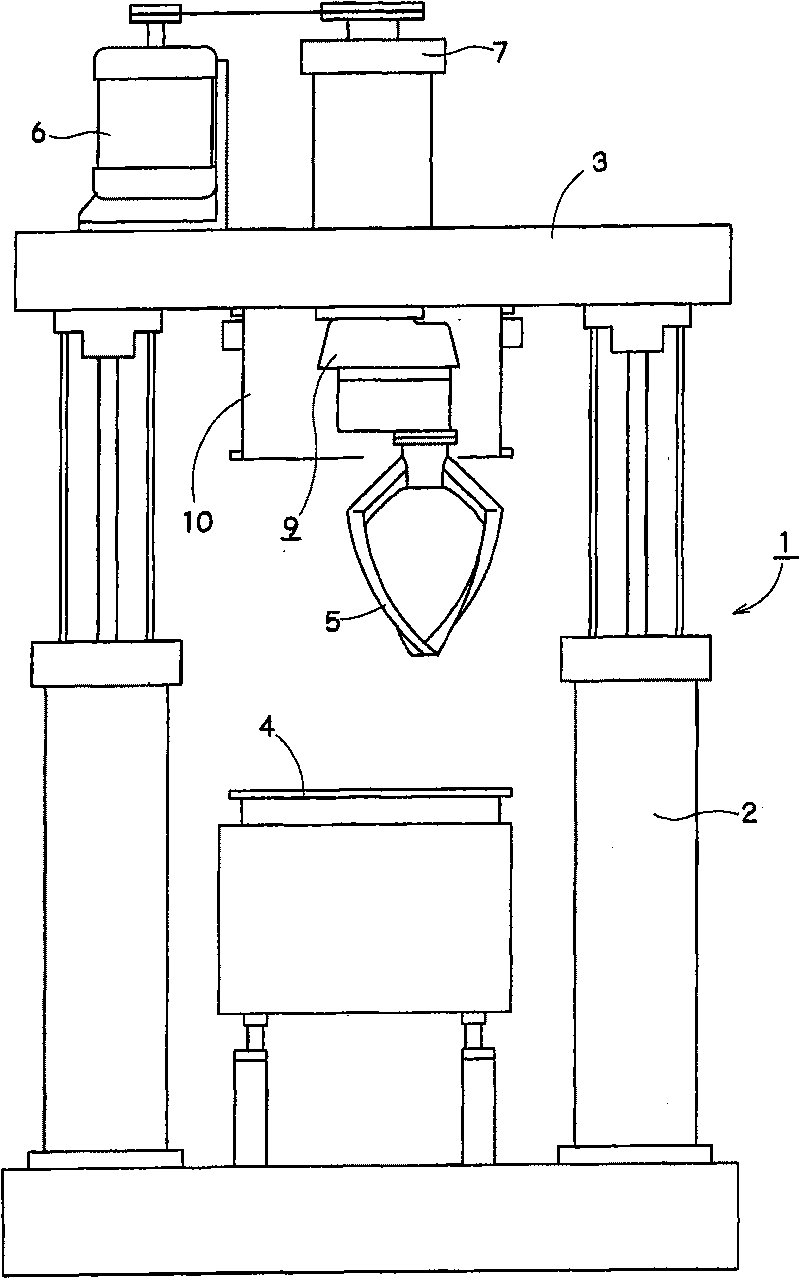

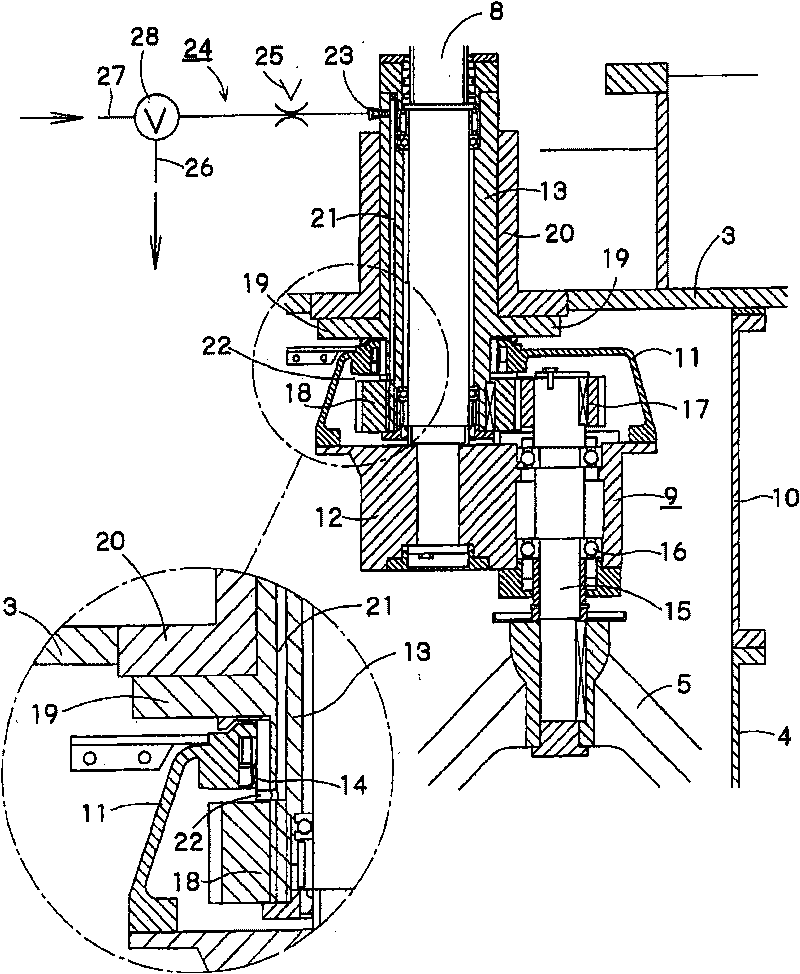

[0012] The present invention can be applied to various planetary mixers, such as figure 1 As shown, the planetary mixer body 1 has a stirring head 3 that is lifted and lowered by the lifting pressure cylinder 2, and the blades 5 are arranged to be inserted into the stirring tank 4 when the stirring head 3 descends. The stirring head 3 is provided with a drive shaft 8 ( figure 2 ), a rotor 9 is connected to the lower end of the drive shaft 8 , and the blades 5 are mounted on the rotor 9 . A shield 10 surrounding the rotor 9 is formed on the lower surface of the stirring head 3 , and the shield 10 can cover the upper surface of the stirring tank 4 as well known.

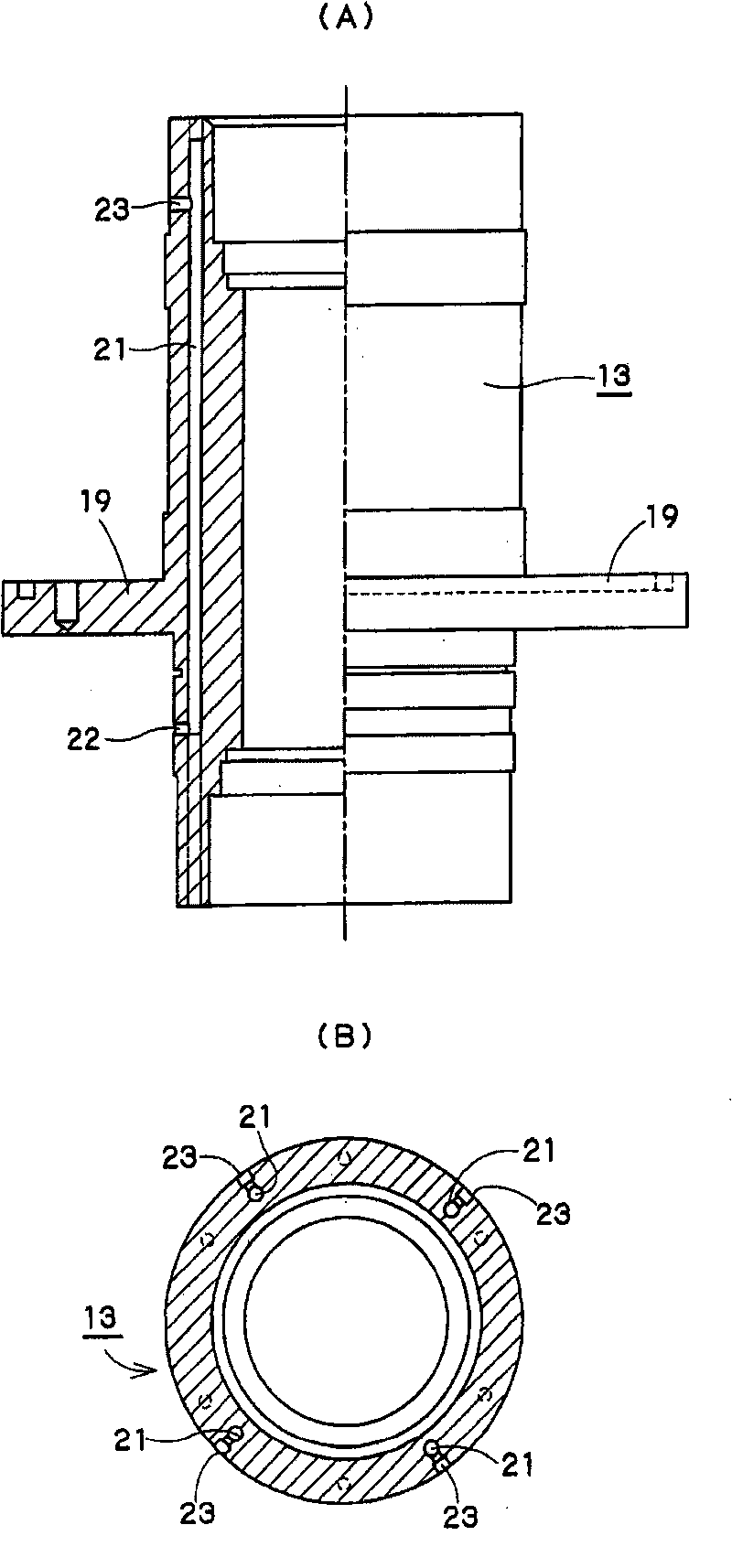

[0013] The rotor 9 includes a gearbox 11 that accommodates a drive member for planetary motion of the vanes 5 , and a bearing housing 12 for a vane shaft that is airtightly connected below the gearbox 11 . like figure 2 As shown, the gear box 11 is connected to the lower part of a support cylinder (bearing cover) ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap