Anti-explosive method of electric welder

A technology of electric welding machine and electric welding handle, which is applied in arc welding equipment, welding rod characteristics, welding equipment and other directions, can solve the problems of generating electric sparks, arc light of electric electrodes, and electric equipments that are easy to generate electric sparks, etc., so as to ensure safety and solve the Effects of explosion-proof problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

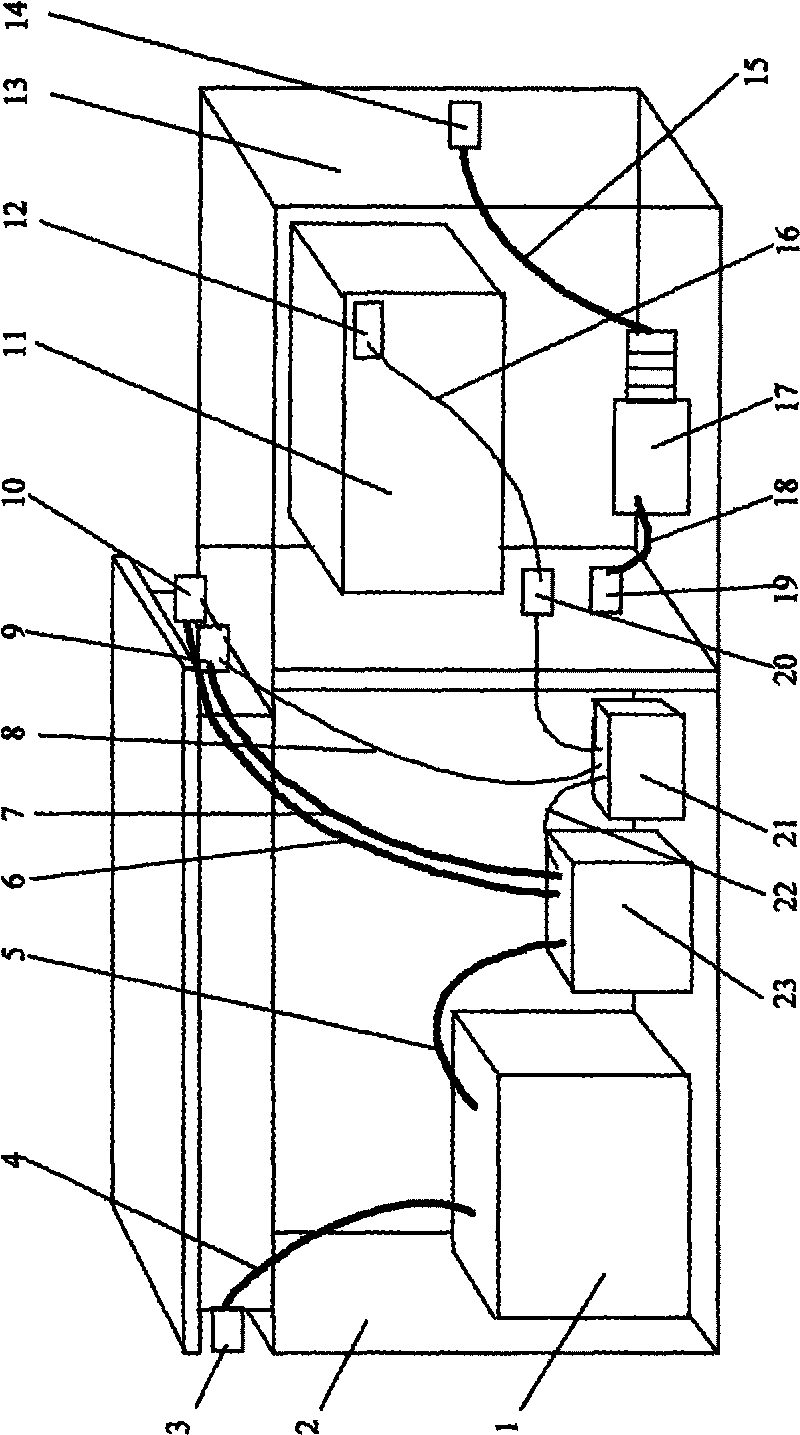

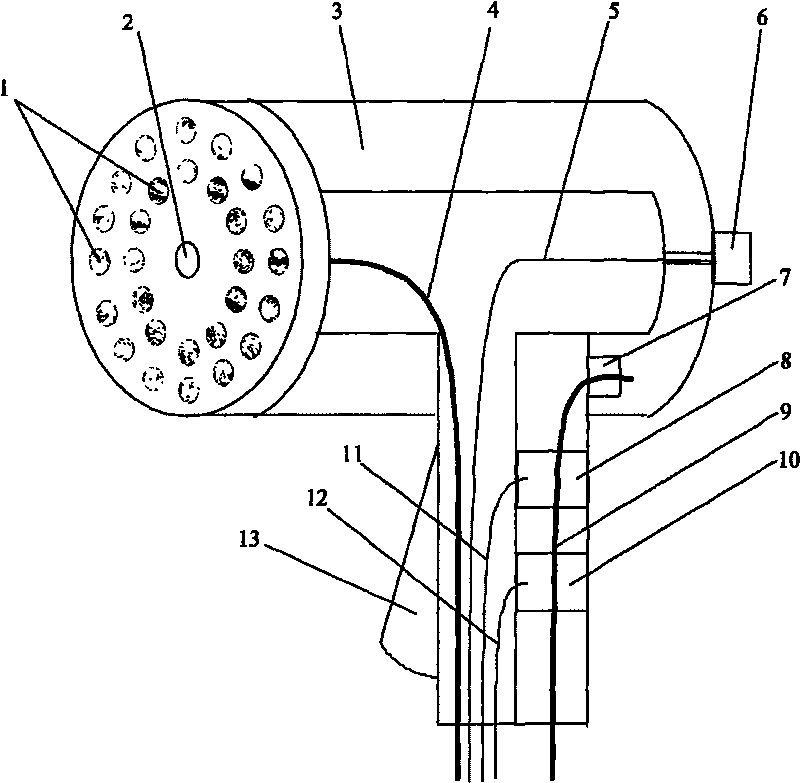

[0020] Put the electrical equipment prone to electric sparks in the flameproof enclosure for explosion-proof, forming an explosion-proof electric welding machine; during the welding process, the arc generated by the electric welding rod is sealed with a high-pressure water curtain to form an explosion-proof electric welding tongs; The ground wire of the welded part adopts two-wire power supply. When one wire is disconnected, the other wire is powered to ensure the reliability of power supply. The connection between the ground wire of the welded part and the welded part uses a contact pressure sensor to monitor the contact state, forming a The welding piece grounding connector with blocking function, when the contact is not good, the sensor sends a signal, which is blocked by the protection control circuit, and the power supply of the welding handle wire and the ground wire of the welded piece is disconnected.

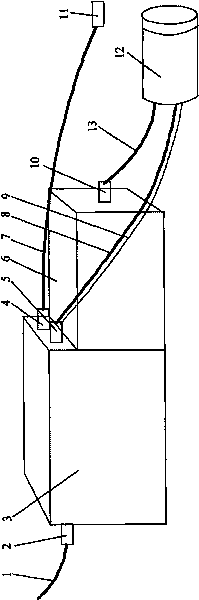

[0021] Implementation column 1: figure 1 This is the overall structura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com