Energy-saving self-traction strand pelletizer for plastic extruder

An energy-saving, self-tracting technology, which is applied in metal processing and other directions, to achieve the effect of saving electric energy, saving traction power, and saving power traction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

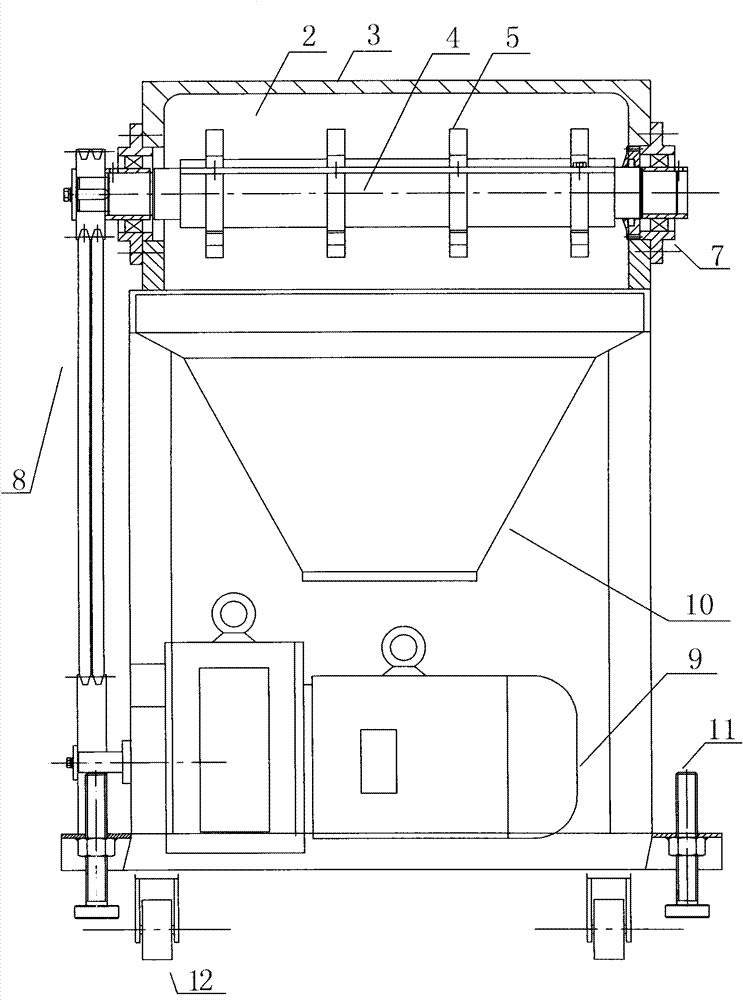

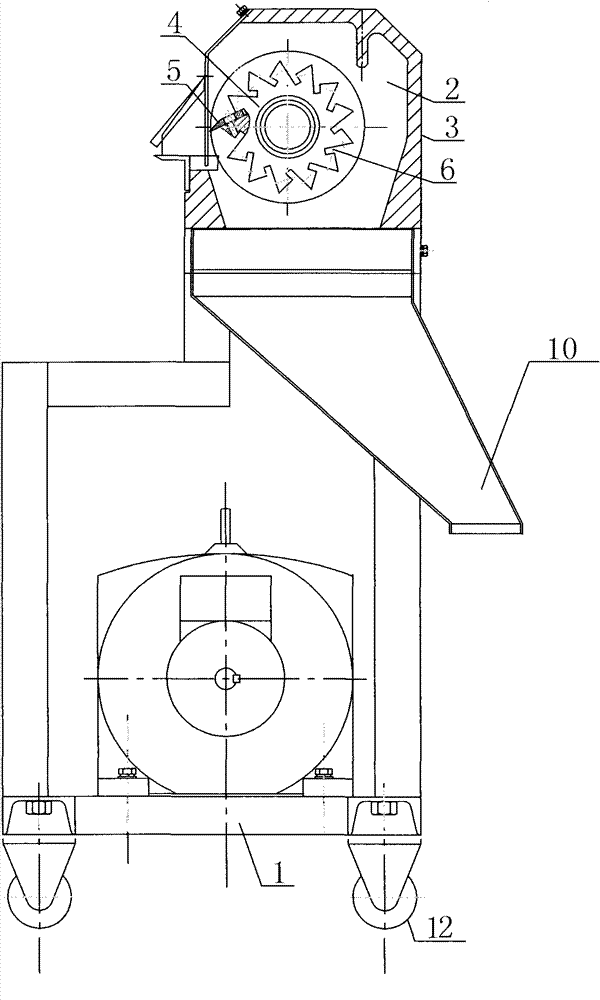

[0037] figure 1 -- image 3 Shown is an energy-saving self-pulling strand pelletizer for plastic extruders.

[0038] The pelletizer includes a metal frame 1 , a pelletizing chamber 2 installed on the frame 1 and a pellet collecting device 10 .

[0039] The cutting chamber 2 includes a cutting knife and a cutting chamber cover 3 .

[0040] The pelletizing knife comprises a cutter shaft 4 and a moving knife blade 5 fixedly installed on the cutter shaft 4 .

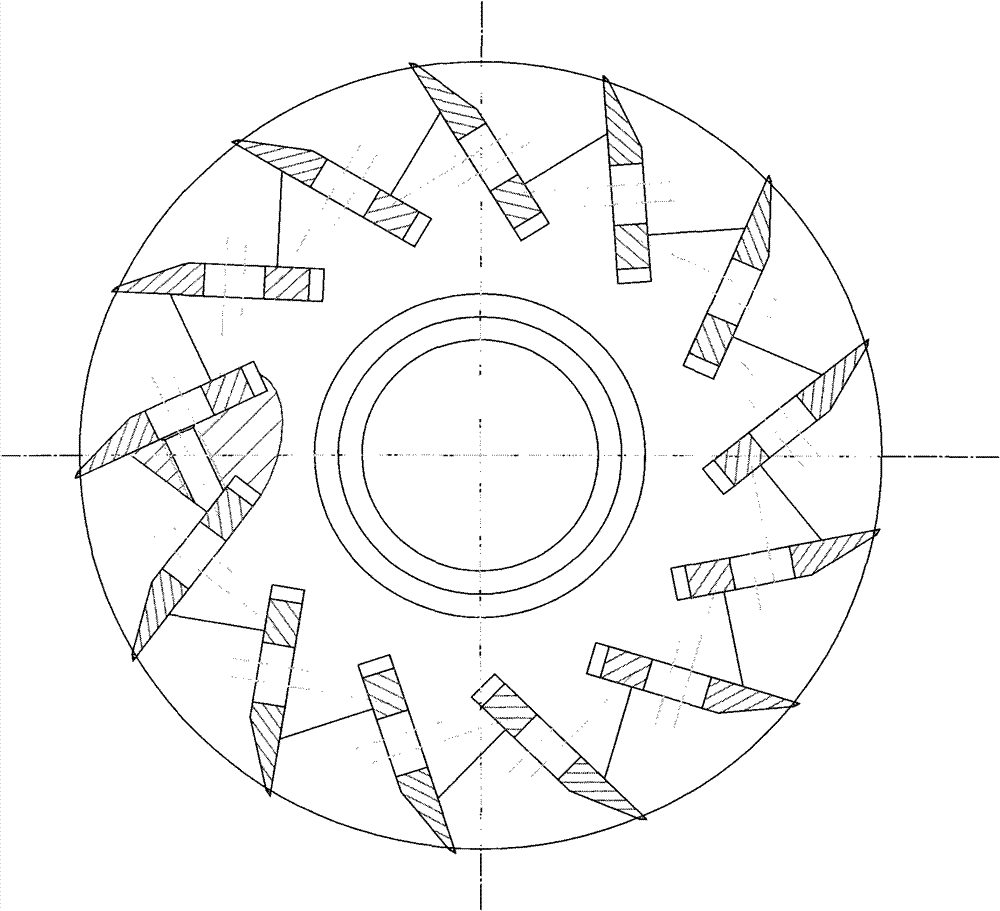

[0041] The cutter shaft 4 is provided with four toothed blade grooves 6 at intervals along the axial direction, referring to figure 1 .

[0042] Thirteen teeth are evenly distributed circularly on each blade groove 6, and each tooth is set at an angle of 30-60° with the radius of the cutter shaft at its position, and the teeth are aligned with the direction of rotation of the cutter shaft (clockwise or counterclockwise). sideways.

[0043] The cutting chamber 2 is set on the upper part of the frame, and two arc beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com