Rapier loom

A rapier loom and warp technology, which is applied in the fields of looms, textiles, textiles and papermaking, etc., can solve the problems of many hanging warps, many broken ends, and many skipped flowers, so as to ensure the quality of the cloth surface and avoid many broken ends , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific structure of the present invention will be further described below in conjunction with the accompanying drawings.

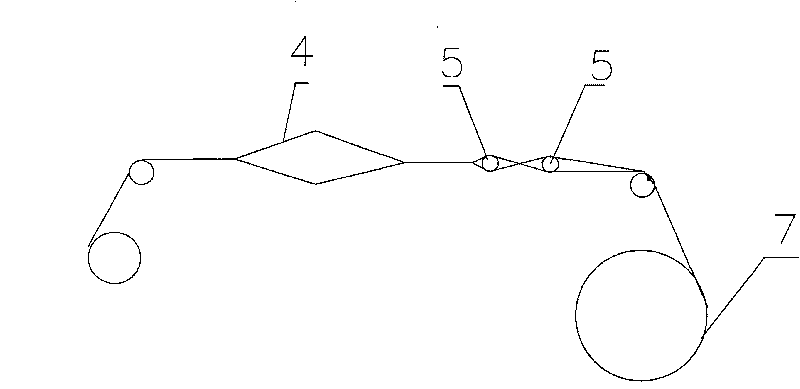

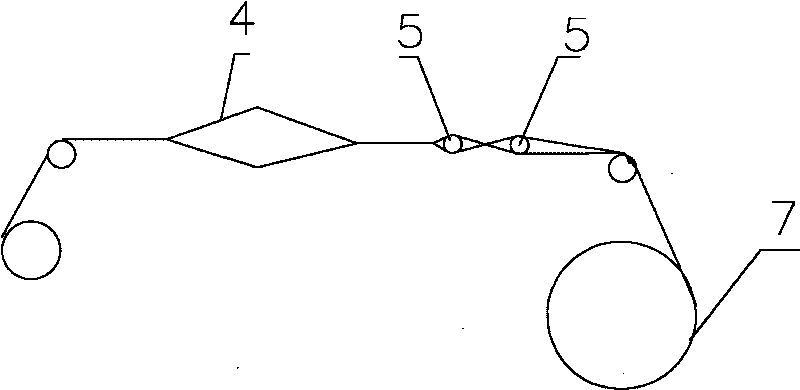

[0010] See attached figure 1 As shown, a rapier loom includes a warp let-off mechanism, a shedding mechanism, a weft insertion mechanism, a weft beating mechanism, and a take-up mechanism. When working, the electric control box coordinates and controls each mechanism to make it operate according to a certain transmission mode and transmission ratio. Come to work to ensure the normal weaving.

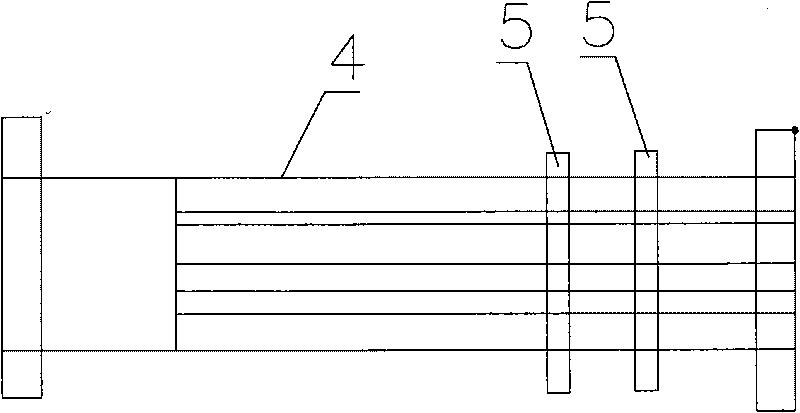

[0011] In the let-off mechanism, the rapier loom has a warp support 4, and the worm gear box is provided with a worm and a worm wheel. The worm screw in the worm gear box on the wallboard drives the worm gear, so that the driving gear coaxial with the worm gear rotates, thereby driving the passive gear and the warp beam 7 to rotate together, and reaching the purpose of sending warp yarn to the warp yarn support 4.

[0012] A pair of splitting rods 5 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com