Tension-adjustable rapier loom

A rapier loom and tension technology, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of easy intertwining of hairiness, poor cloth surface quality, and many hanging warps, etc., and achieve uneven tension , Eliminate weft density faults and reduce cloth surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

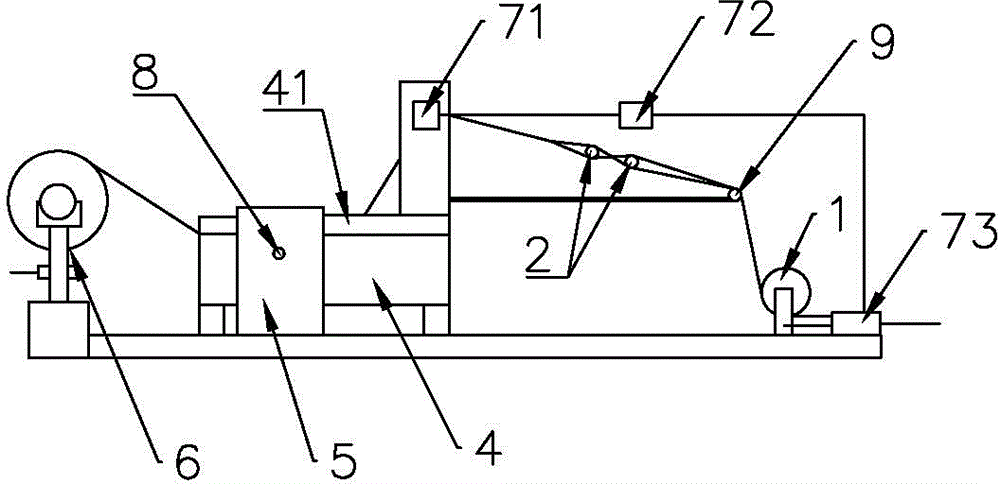

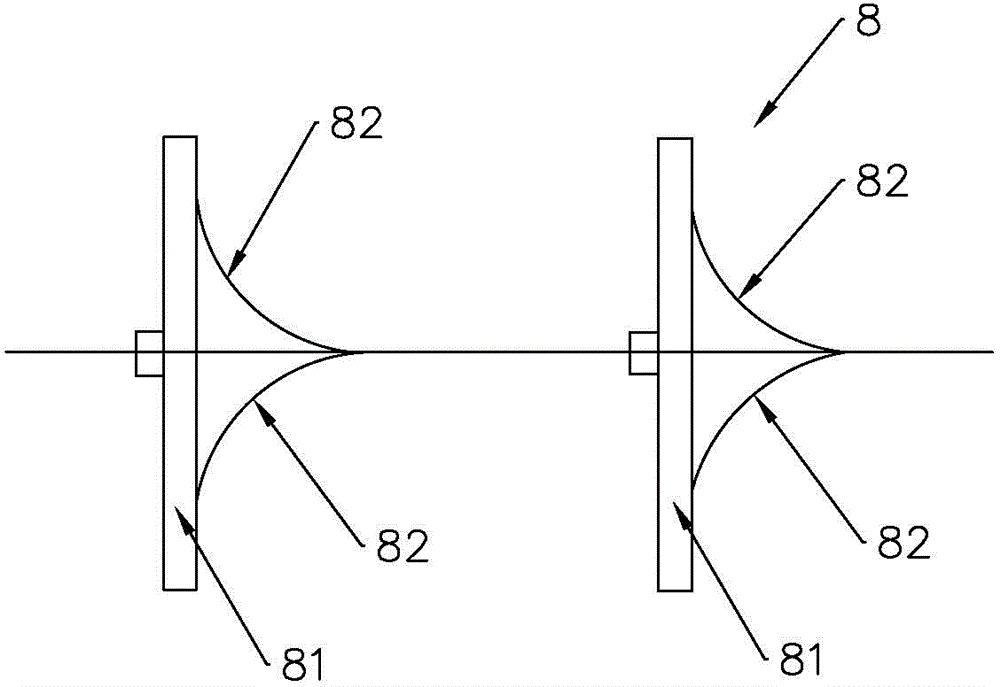

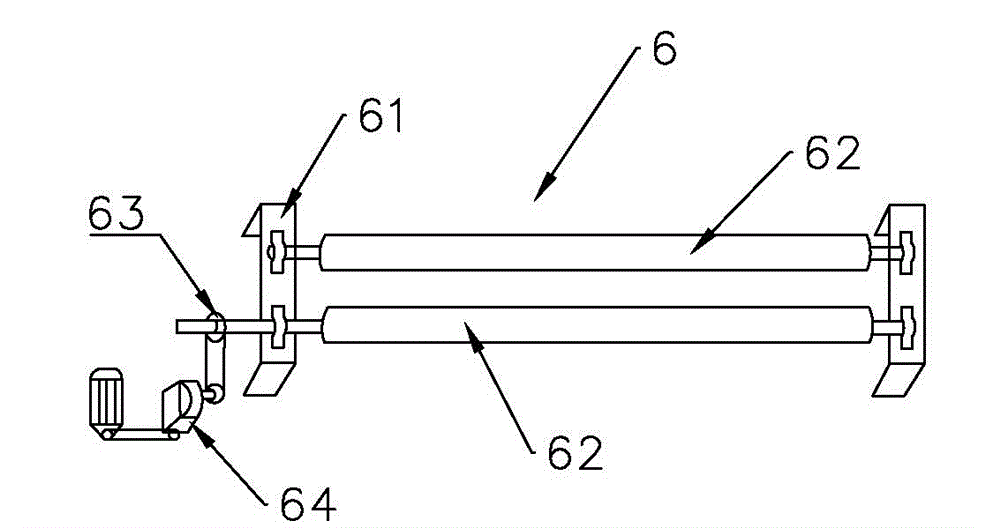

[0040] Such as Figure 1 to Figure 3 As shown, a tension-adjustable rapier loom includes a warp beam 1, a warp let-off mechanism 3, a workbench 4, a weft feeding mechanism 5, and a cloth winding mechanism 6; a warp beam 1 and a warp let-off mechanism 3 are provided with A splitting mechanism that prevents warp yarns from being twisted and mixed; the warp let-off mechanism 3 is provided with a tension sensing mechanism, and the weft feeding mechanism 5 is provided with a weft insertion mechanism 8; Sprocket 63, decelerating motor 64, cloth rolling shaft 62 is installed on the cloth rolling support 61, and slip sprocket wheel 63 is installed on one end of cloth rolling shaft 62, and reduction motor 64 is installed on the bottom of slip difference sprocket wheel 63, and reduction motor 64 drives The slip sprocket 63 further drives the cloth take-up shaft 62 to rotate.

[0041] A splitting mechanism is set between the warp beam 1 and the let-off mechanism 3, and the adjacent warp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com