Construction method of rubber shock insulation support

A technology of rubber seismic isolation bearing and construction method, which can be applied in the direction of earthquake resistance, building components, building structure, etc., can solve the problems of complicated construction and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

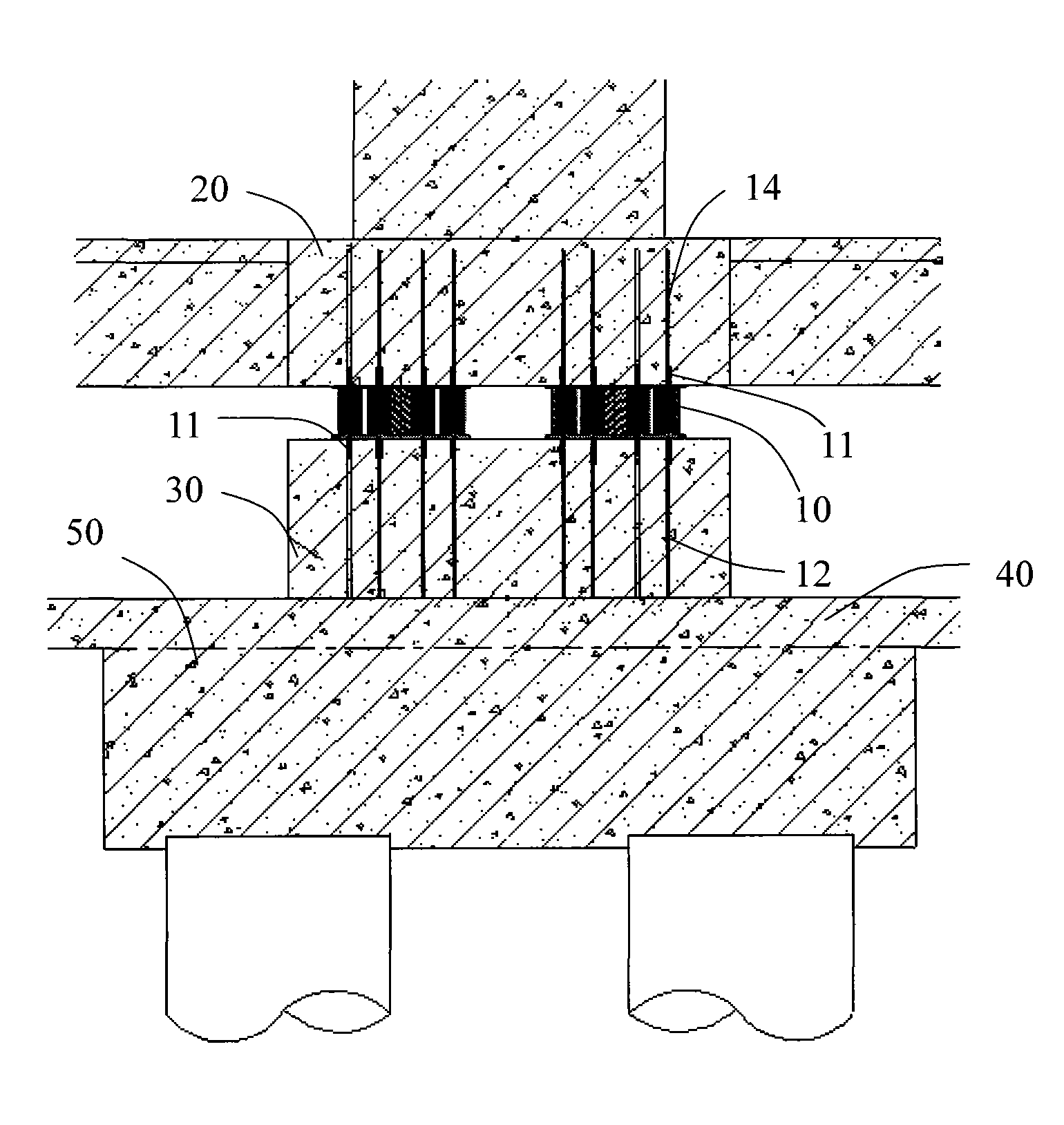

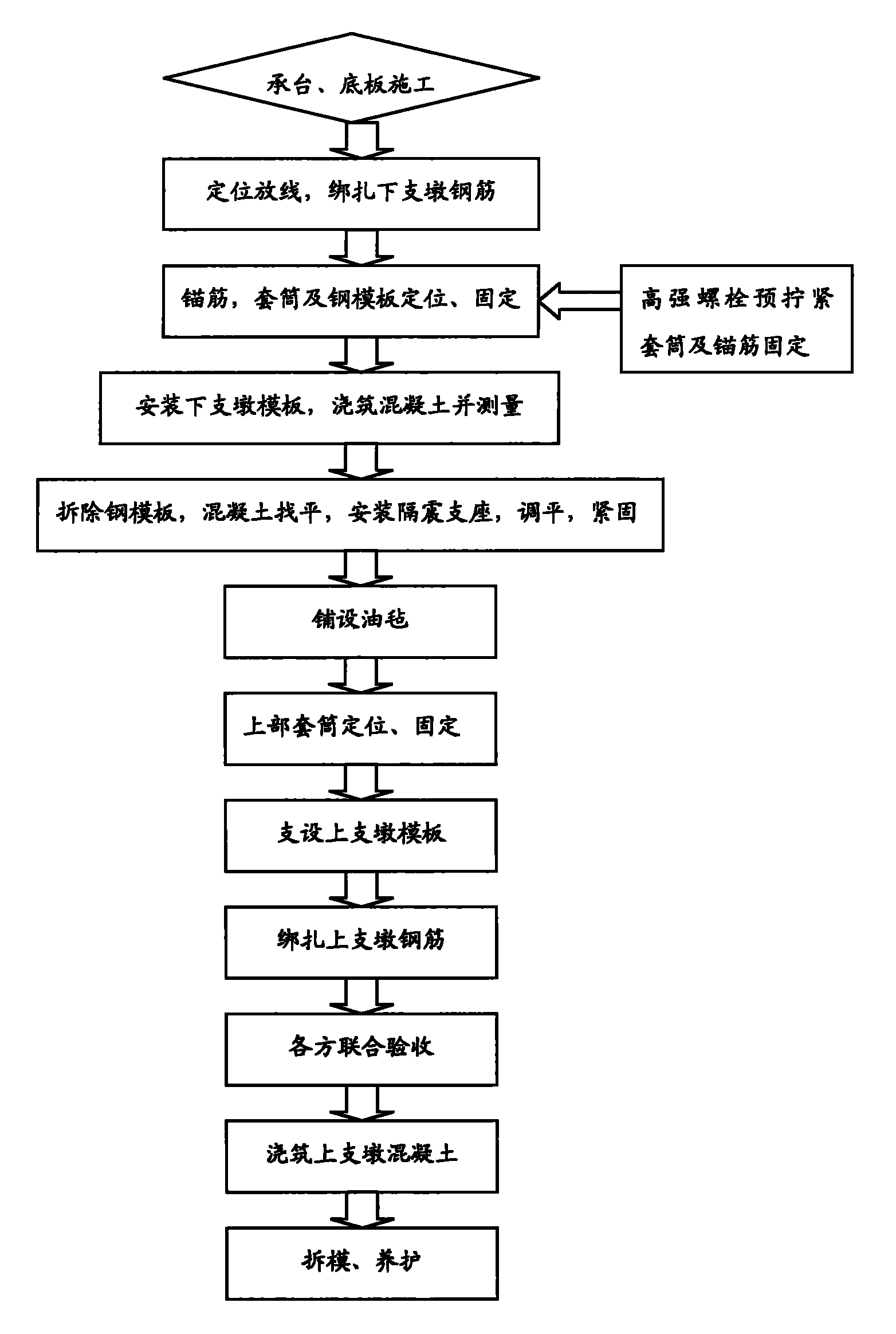

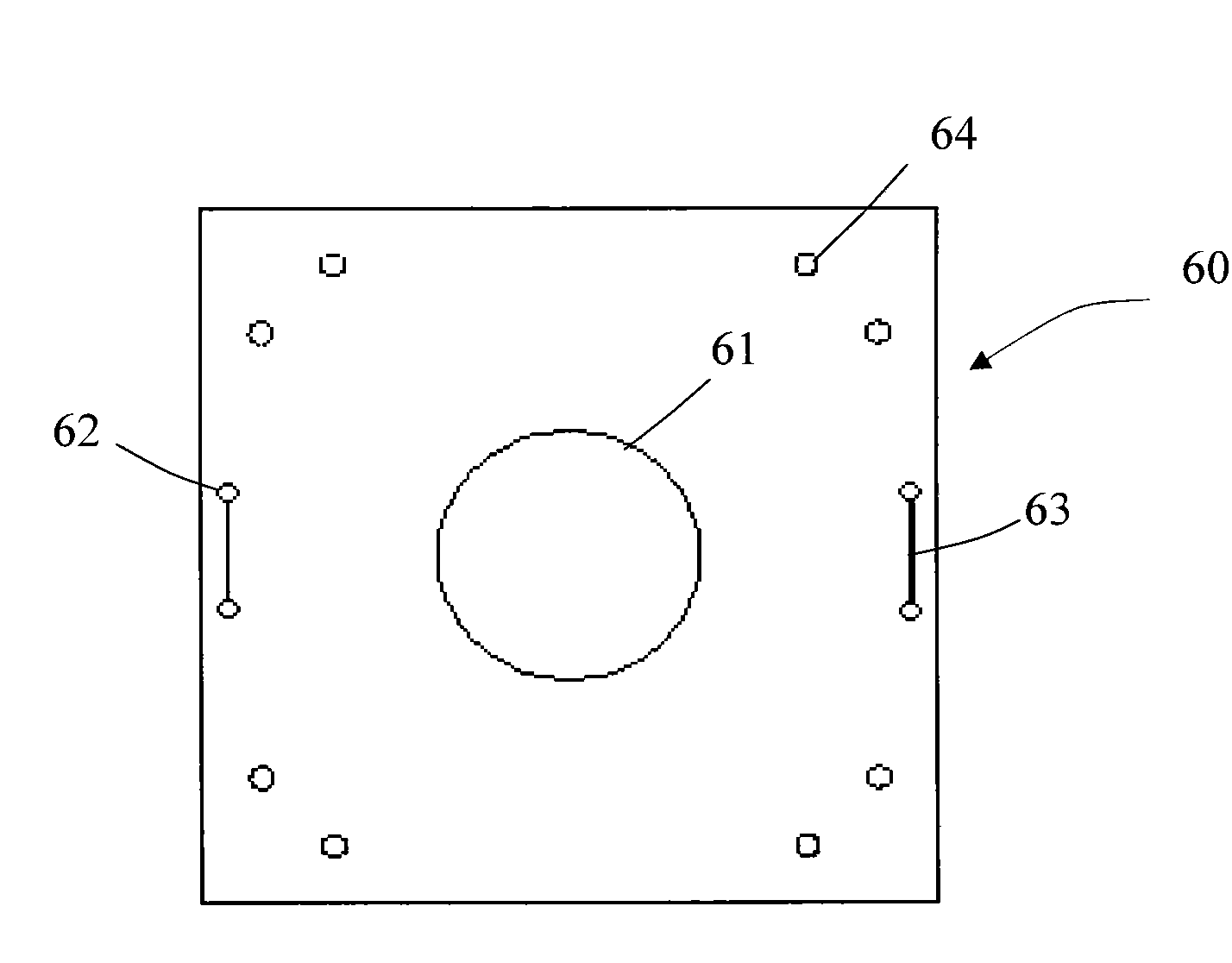

[0026] The construction method of rubber seismic isolation bearing provided by the present invention, the design schematic diagram of its seismic isolation bearing is as follows figure 1 As shown, it includes a rubber shock-isolation bearing 10 with a diameter of 1m, a sleeve 11, an anchor bar (anchor bar) 12, an upper pre-embedded bar 14, an upper buttress 20, a lower buttress 30, a bottom plate 40 and a cap 50; combine figure 2 Shown, construction process of the present invention is:

[0027] For the construction of the cap 50 and the bottom plate 40, the upper and lower piers 20, 30 of the seismic isolation support 10 are constructed separately from the cap 50 and the bottom plate 40. The pre-embedding is accurate. After the pre-embedding is completed, the cap and the bottom plate are poured with concrete and vibrated to make them level.

[0028] When the concrete strength of the platform 50 and the bottom plate 40 reaches 1.2N / mm 2 , measurement and positioning can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com