Structure and method for reinforcing walls filled in gob-side retained tunnel by arranging three-dimensional reinforcing ribs in walls

A technology for filling walls and reinforcing ribs, which is applied in the direction of fillings, safety devices, earthwork drilling and mining, etc. It can solve problems such as difficult to effectively control the displacement of walls, and achieve the effects of wide practicability, simple and fast construction, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

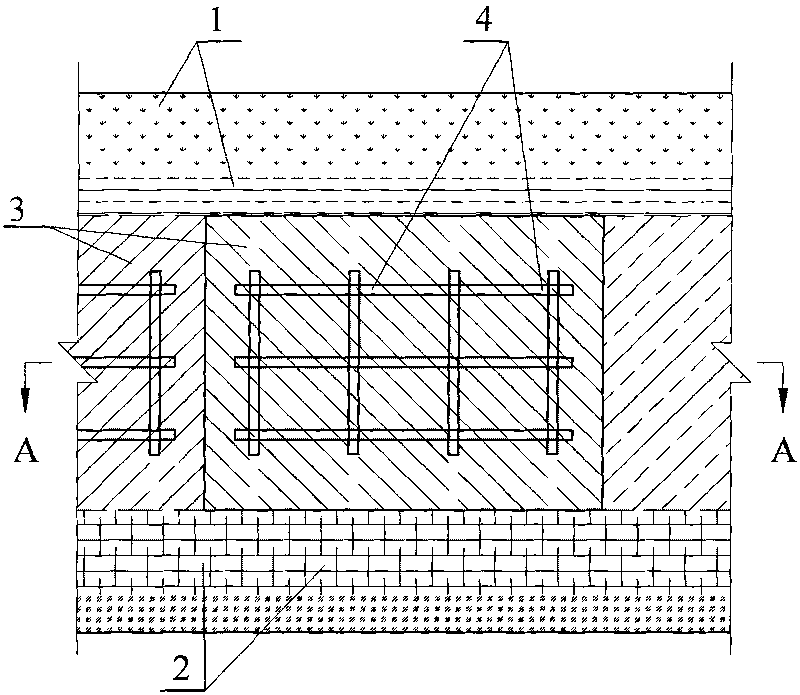

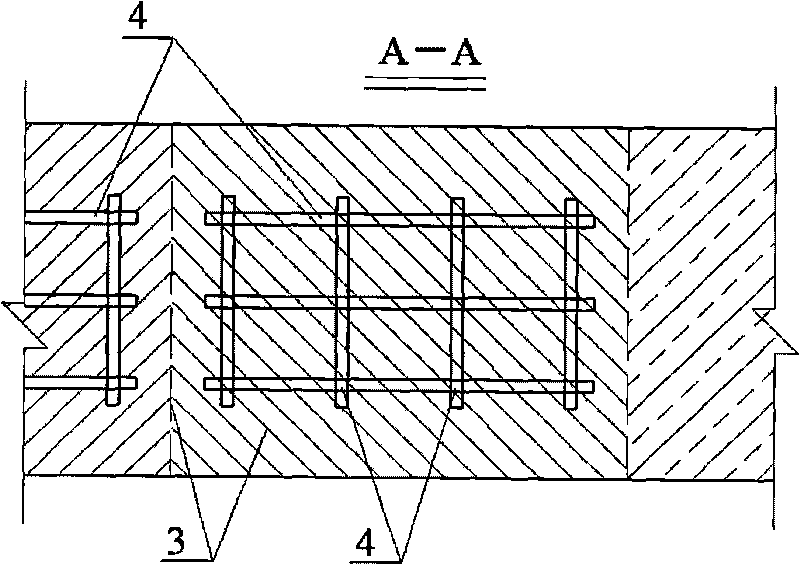

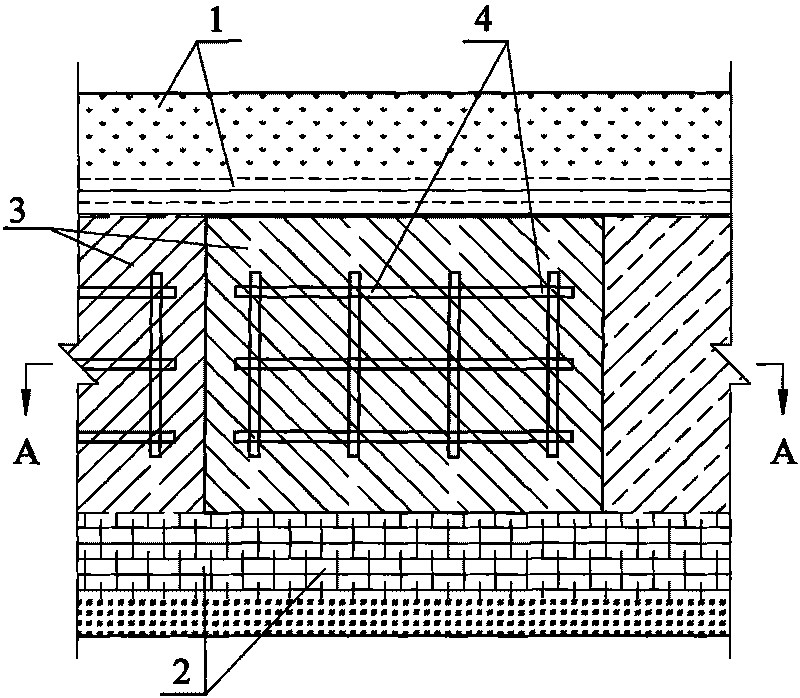

[0020] The built-in three-dimensional reinforcing rib of the present invention reinforces the filling wall structure of gob-side retaining, which is composed of a filling wall 3 filled between the top plate 1 and the bottom plate 2, and grid-shaped three-dimensional reinforcing ribs 4 installed in the filling wall 3 . Grid-like three-dimensional reinforcing ribs 4 are braided with threaded steel, round steel or flat steel, and the row spacing between the four braided three-dimensional reinforcing ribs is 0.8-1.6m.

[0021] The built-in three-dimensional reinforcing rib of the present invention reinforces the filling wall method of gob-side entry retaining. After mining at the working face, a prefabricated or on-site grid-shaped three-dimensional reinforcing rib 4 is placed in the area to be filled, and the grid-like three-dimensional reinforcing rib 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com