Direct gasolene injection engine equipped with oil fuel pump

A gasoline direct injection, fuel pump technology, applied in combustion engines, internal combustion piston engines, engine components, etc., can solve problems such as large space, increased weight and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Exemplary embodiments of the present invention will hereinafter be described in detail with reference to the accompanying drawings.

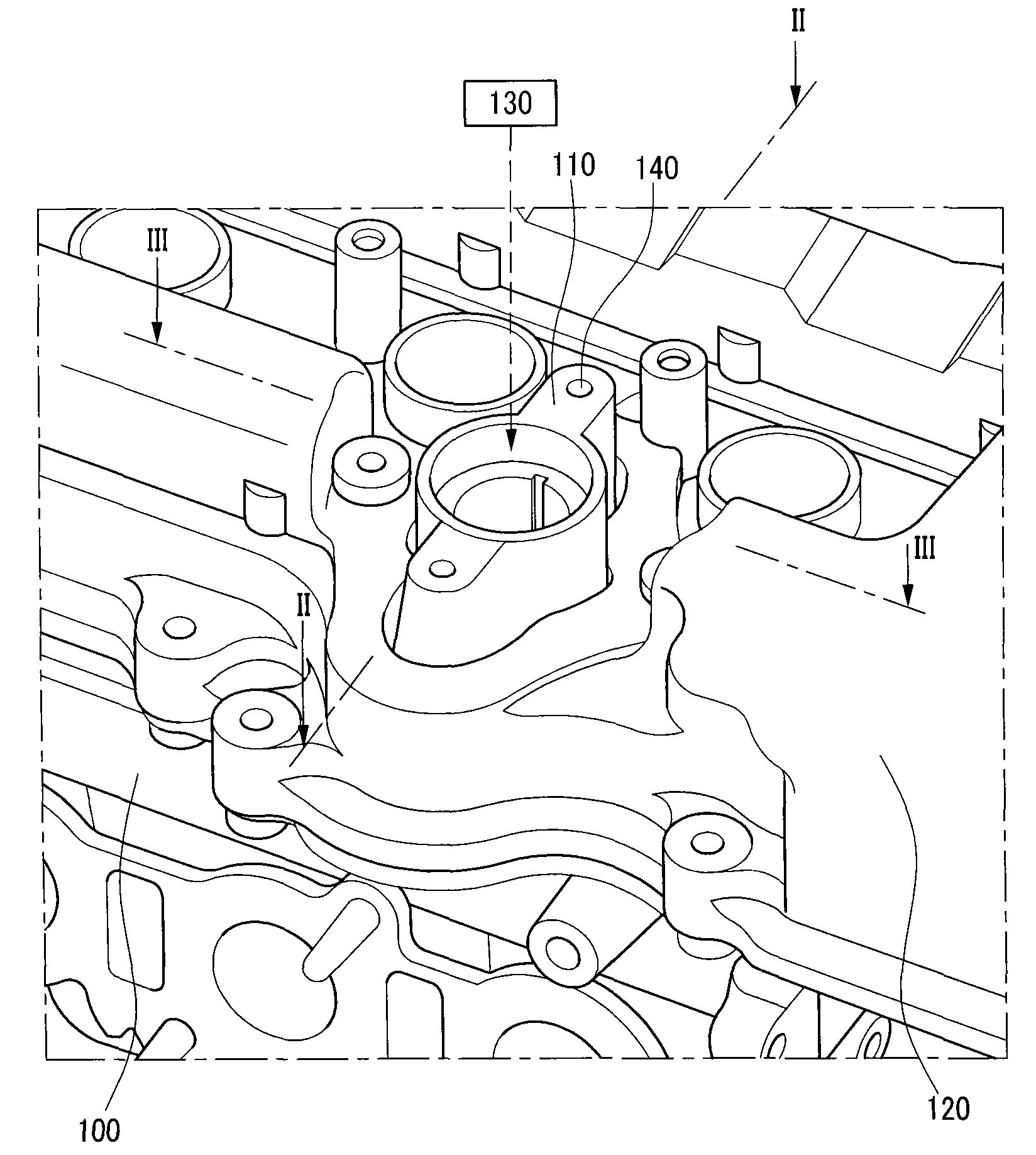

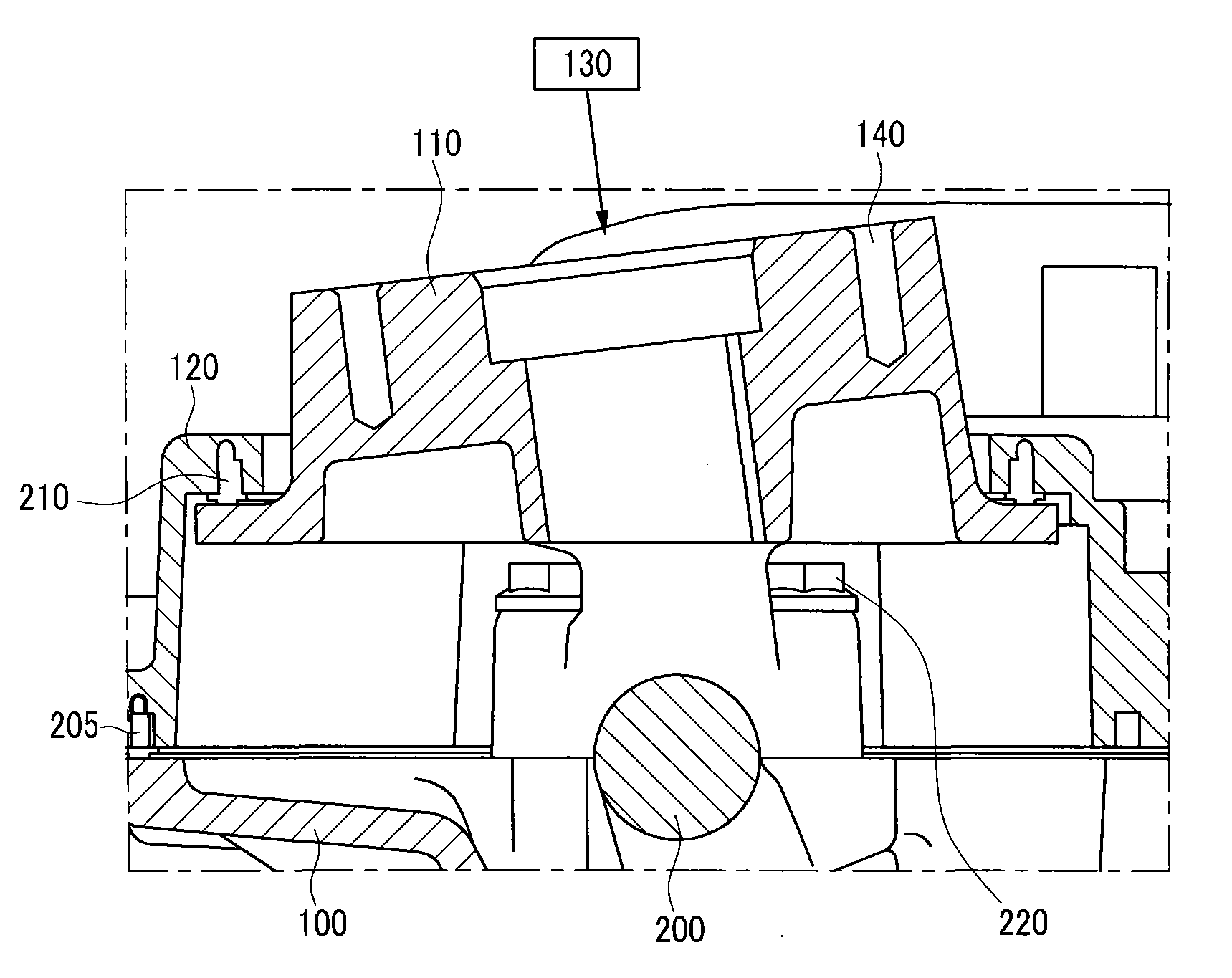

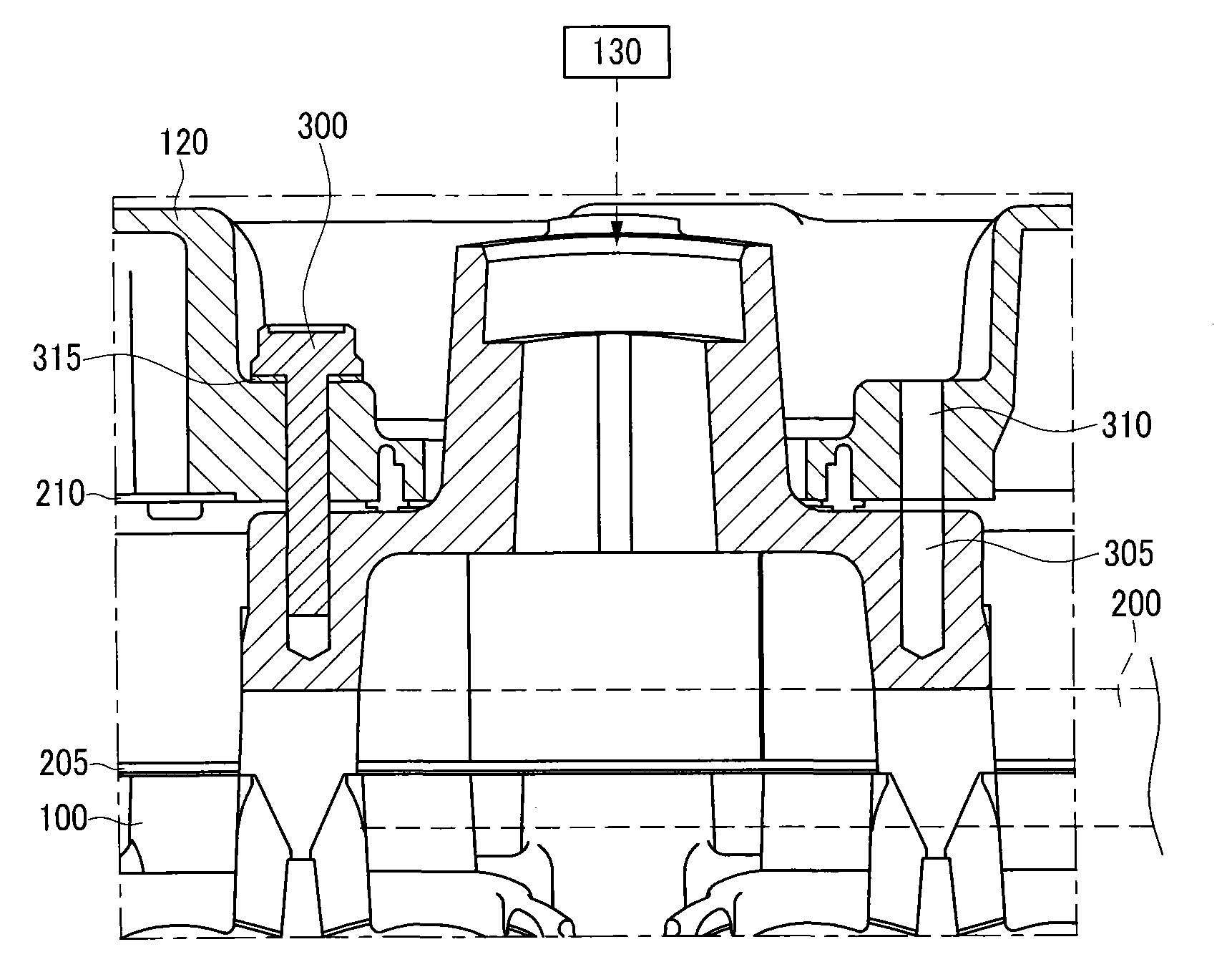

[0040] figure 1 is a partial perspective view of a gasoline direct injection engine equipped with a fuel pump device according to an exemplary embodiment of the present invention.

[0041] refer to figure 1 , the engine includes a cylinder head 100 , a cylinder head cover 120 and an adapter 110 .

[0042] The cylinder head cover 120 is located above the cylinder head 100, and the cylinder head cover 120 is fixed to the cylinder head 100 by fixing bolts at the edge of the cylinder head cover.

[0043] The adapter 110 is combined with the cylinder head 100, and the mounting hole 600 ( Image 6 ) is formed in the cylinder head cover 120 through which the adapter extends.

[0044] A mounting surface to which the fuel pump 130 is attached is formed on an upper end surface of the adapter 110, and a first bolt hole 140 is formed on the mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com