Method and device for preventing leak through of spiral lift tap

A technology of spiral lifting and faucet, which is applied in the direction of valve operation/release device, valve device, sliding valve, etc., can solve the problems of faucet dripping, difficult to promote, high cost, etc., and achieve the effect of solving dripping problem and eliminating wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

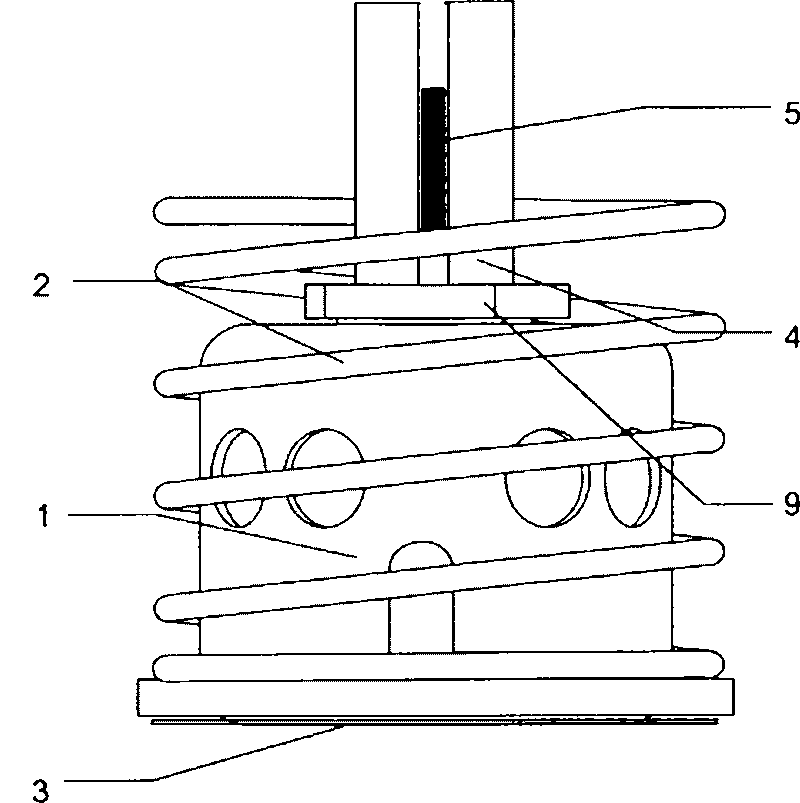

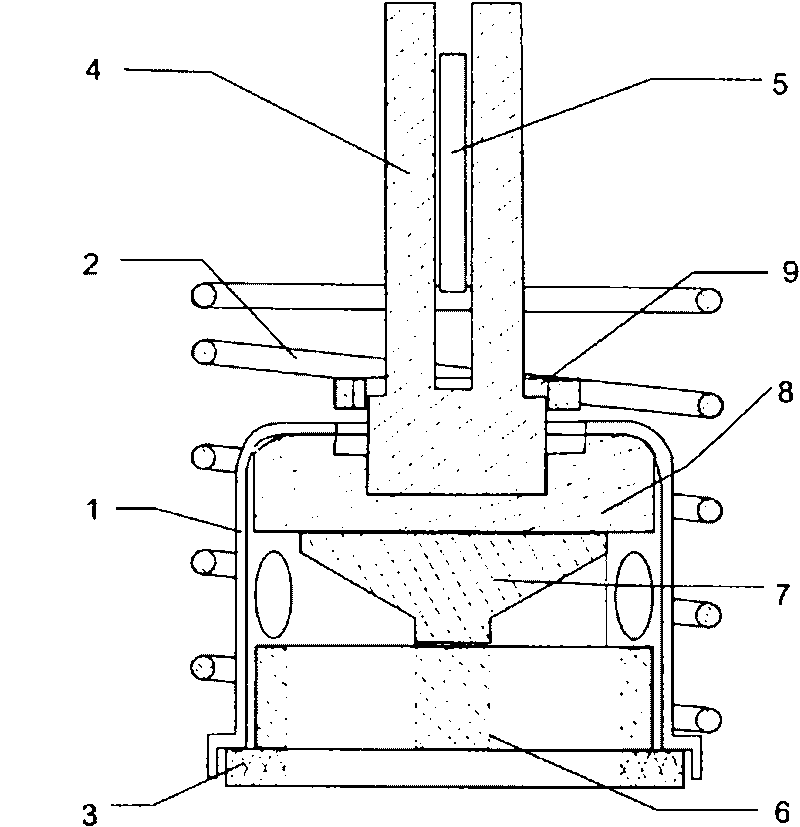

[0053] A method of preventing dripping from a spiral lift faucet comprising:

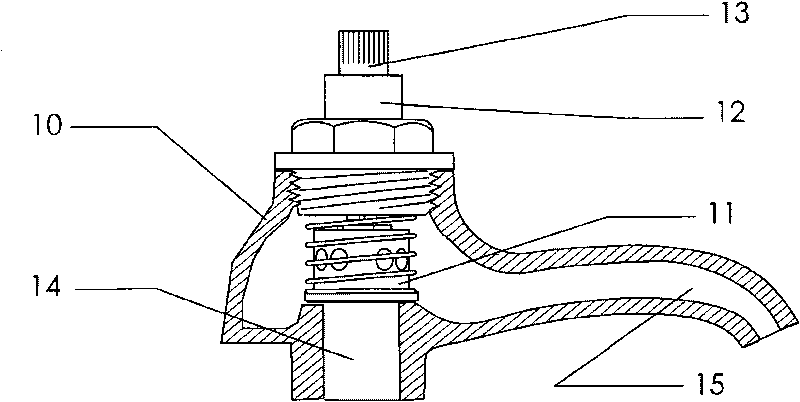

[0054] (1) Set a new device between the water inlet of the spiral lift faucet and the cock at the lower end of the faucet's rotating handle (the original space for placing the rubber dense valve and the washer seat), the ceramic valve assembly, its size and size The volume is similar to the original Huasi and Huasi seat;

[0055] (2) Use an elastic device to compress the ceramic valve assembly above the water inlet of the faucet; a spring structure is used in this implementation, and a precision thread adjustment structure or a precision matching sliding adjustment structure can also be used. The spring presses the ceramic valve assembly under the cock, so that the valve core can get normal working pressure directly, instead of indirectly generating working pressure by the screw structure on the handle of the faucet like the previous rubber washer and washer seat;

[0056] (3) The ceramic valve pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com