Detector for hydraulic torque wrench

A technology of torque wrench and calibration instrument, which is applied in the direction of instruments, force/torque/power measuring instrument calibration/testing, measuring devices, etc., which can solve the problems of hydraulic torque wrench damage, difficulty in manufacturing, easy damage, etc., and achieve convenient plugging , simple structure, safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the embodiments shown in the accompanying drawings.

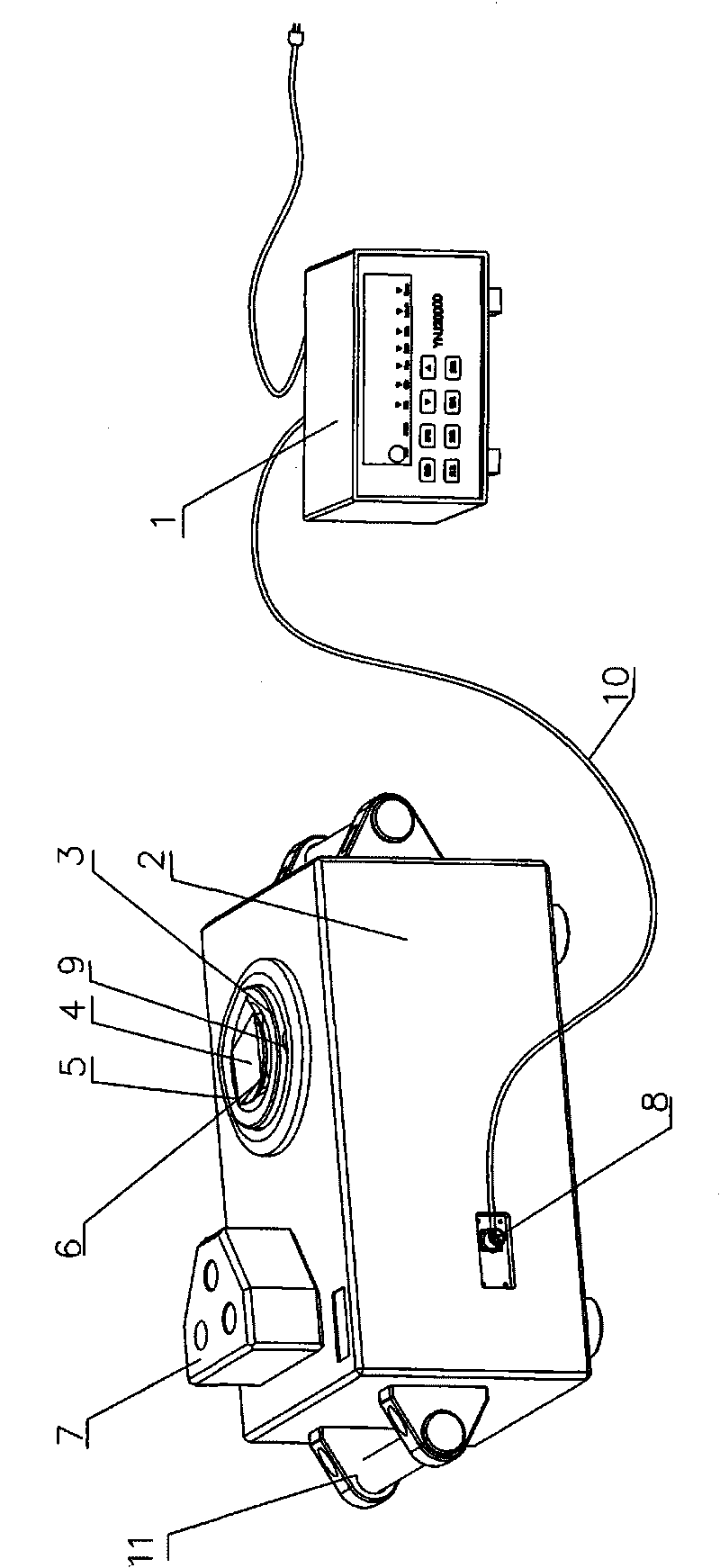

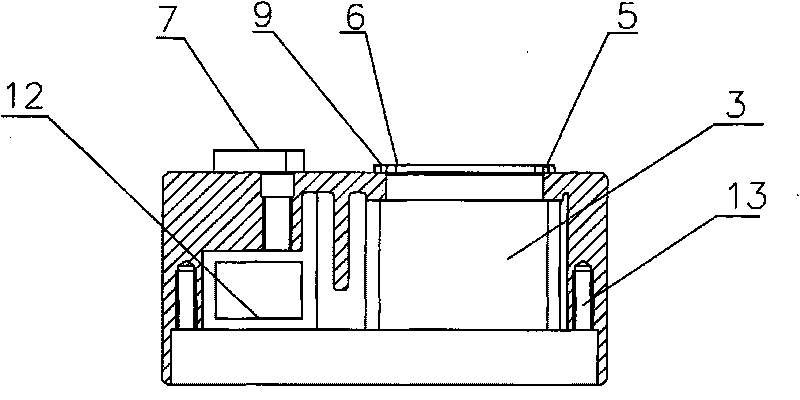

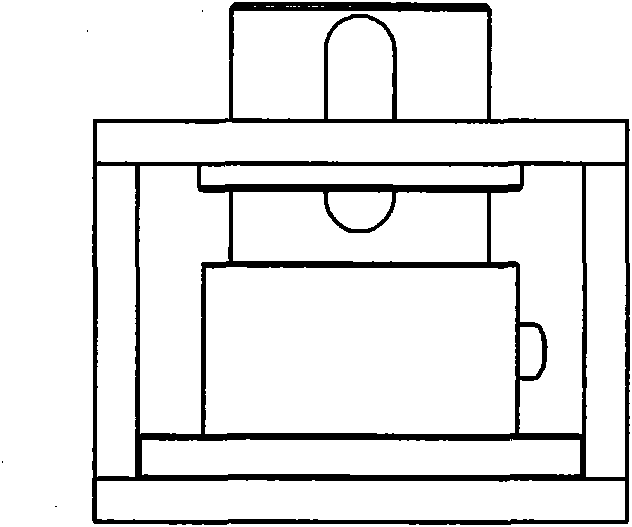

[0020] Such as figure 1 As shown, the hydraulic wrench calibrator of the present invention mainly includes a torque sensor 3 fixed on the housing 2 and a reaction arm block 7 as a thrust positioning mechanism. The signal output end of the torque sensor is connected to the digital display 1 equipped with the operation panel through the test interface 8 installed on the housing 2 through the connection line 10; the upper end surface of the torque sensor 3 has a square hole 4, and the lower section of the adapter 6 It is plugged into the square hole 4; the reaction arm block 7 is fixed on the housing 2 by bolts, and its horizontal position can be adjusted.

[0021] The upper part of the sensor 3 is fixed on the housing 2 by the retaining ring 5 and the bearing 9, and the lower part is fixed together by the bolt and the bottom plate 13 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com