Non-woven wipe for wiping optical lenses and production method thereof

A technology of optical lenses and production methods, applied in optics, optical components, medical science, etc., can solve the problems of easy dust absorption, secondary pollution of lenses, corrosion of lenses, etc., and achieves convenient carrying and use, good wiping effect, and strong cleaning ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

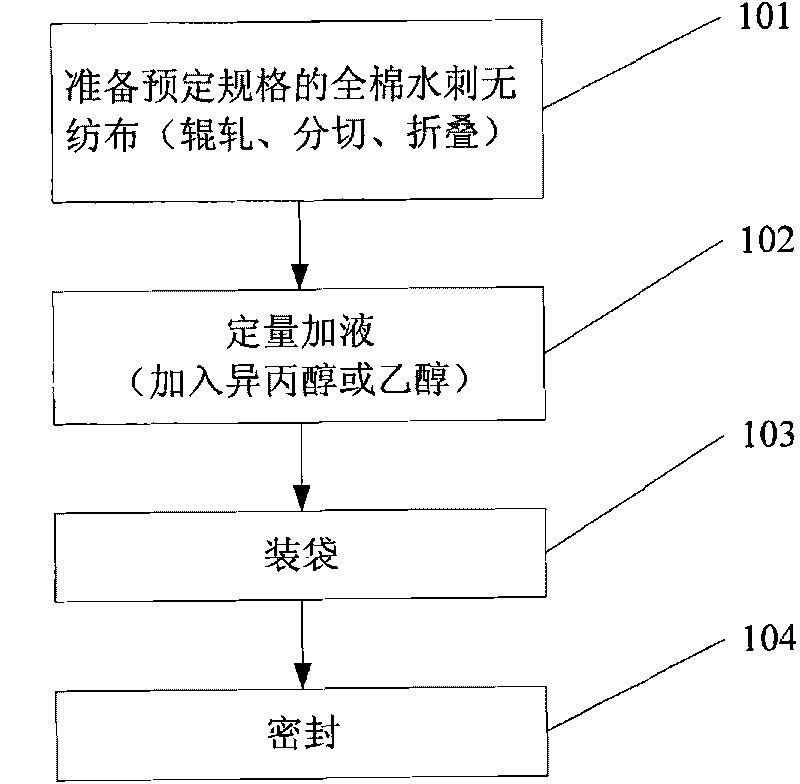

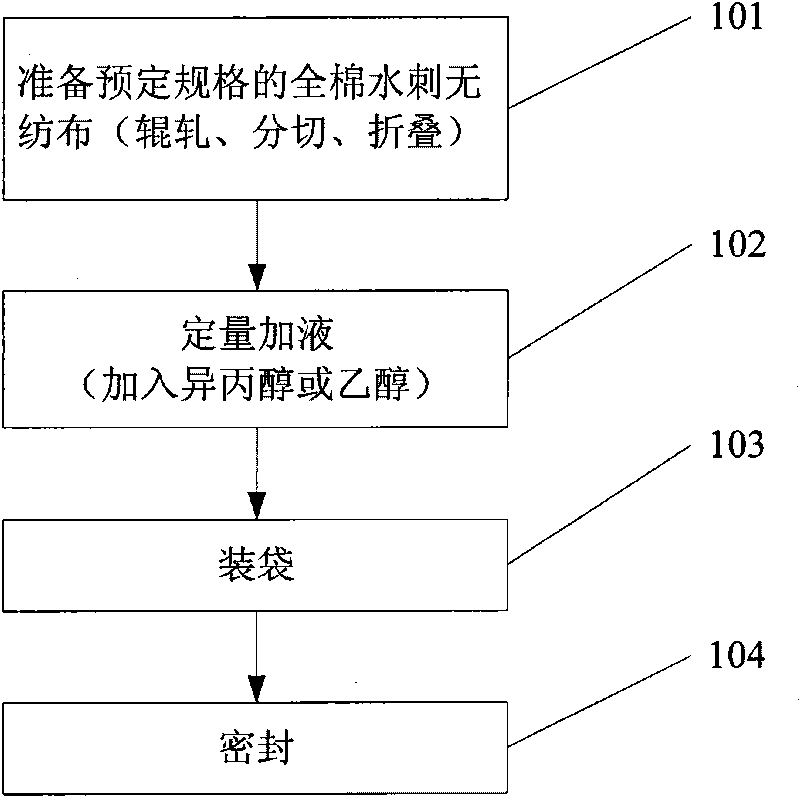

[0022] Hereinafter, the present invention will be further described in detail through specific embodiments in conjunction with the accompanying drawings.

[0023] The non-woven wet wipes for wiping optical lenses of the present invention include non-woven fabrics. The non-woven fabrics absorb sterilizable and volatile chemical reagents, and the non-woven fabrics are covered with a sealed bag. In this embodiment, the non-woven fabric is a cotton spunlace non-woven fabric, and the sterilizable and volatile chemical agent is preferably a colorless liquid, specifically isopropanol or ethanol, preferably isopropanol. Liquid is added so that the liquid content of the non-woven fabric is 5% to 200%. In one embodiment of the present invention, the size of the non-woven fabric is 100 mm×150 mm, folded into 2 or 4 layers, and about 0.8 g of isopropanol is added. The sealed bag is preferably an aluminum foil bag. For ease of use, an easy-tear opening is provided on one side of the sealed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com