Energy-saving lamp using high-power spiral energy-saving lamp tube

An energy-saving lamp and high-power technology, which is applied to parts of gas discharge lamps, discharge lamps, discharge tubes, etc., can solve problems such as difficulty in meeting large-scale production, increasing manufacturing difficulty, and heating and bending of long glass tubes. Achieve the effect of satisfying large-scale production, improving reliability and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

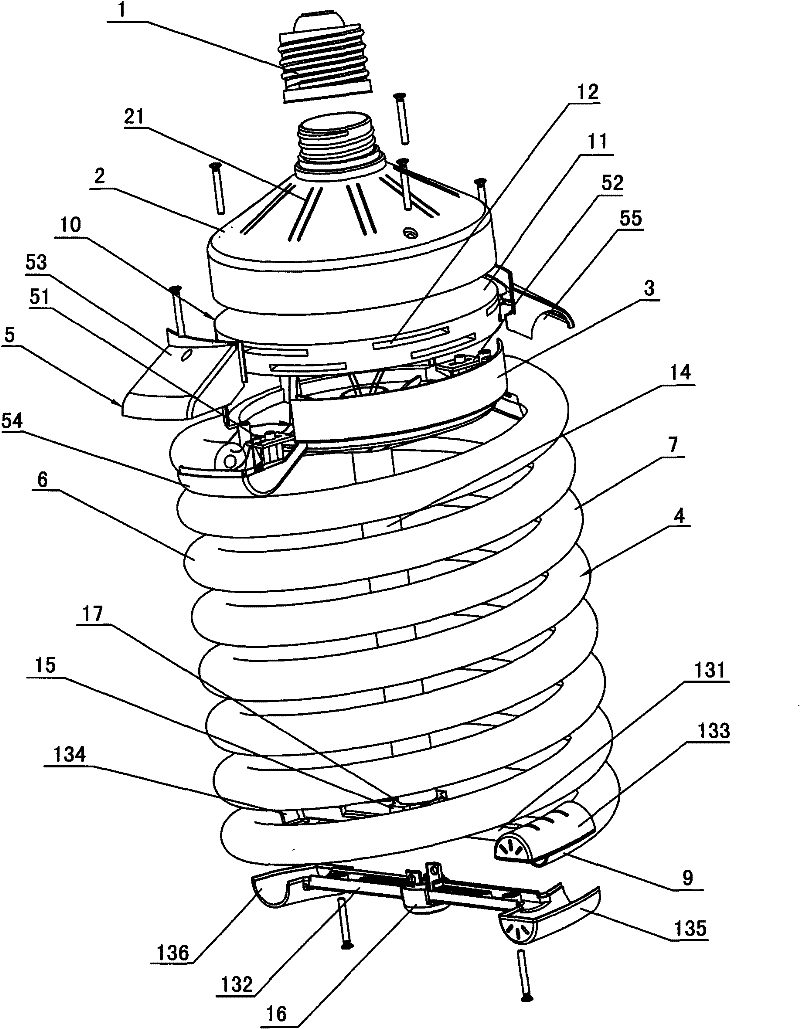

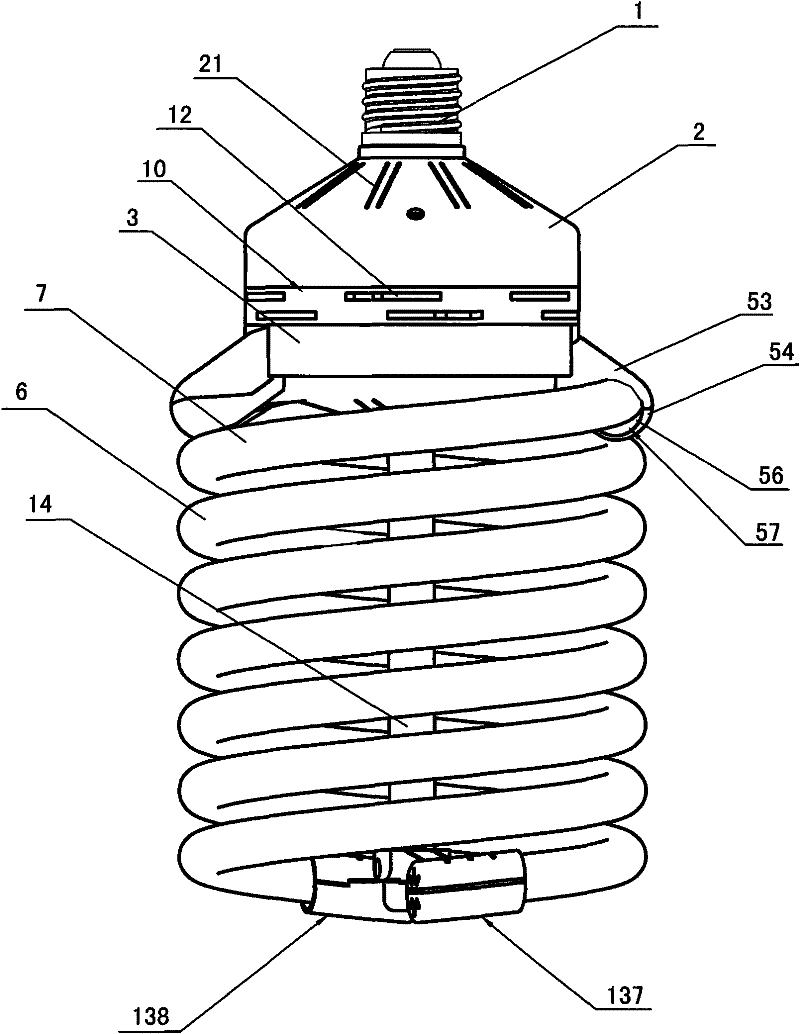

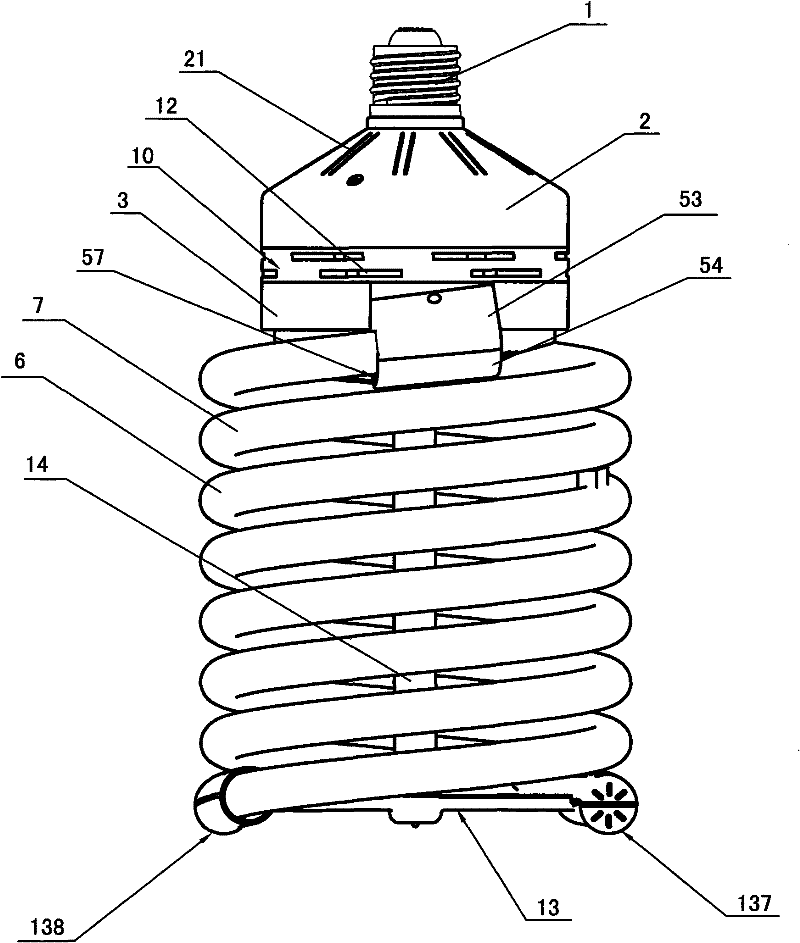

[0031] As shown in the figure, an energy-saving lamp using a high-power spiral energy-saving lamp tube includes a lamp cap 1, an upper cover 2, a lower cover 3, a ballast (not shown in the figure) and a double-helix energy-saving lamp tube 4, and the upper cover The upper end of 2 is connected with the lamp holder 1, and the upper cover 2 is connected with the lower cover 3 through existing fasteners such as screws. Matching oblique interface 5 . Here, the double-helix energy-saving lamp tube 4 used includes two first single-helix lamp tubes 6 and second single-helix lamp tubes 7 with the same structure and both cylindrical shapes. Figure 8 and Figure 9 The structure of the single helical lamp is given ( Figure 8 and Figure 9 marked with the first single helical lamp), the helical direction of the first single helical lamp 6 and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com