Weaving machine having a device for selecting the weft thread colour

A weft yarn and color selection technology, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of operation obstruction, obstruction, weft yarn damage, etc., and achieve the effect of easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

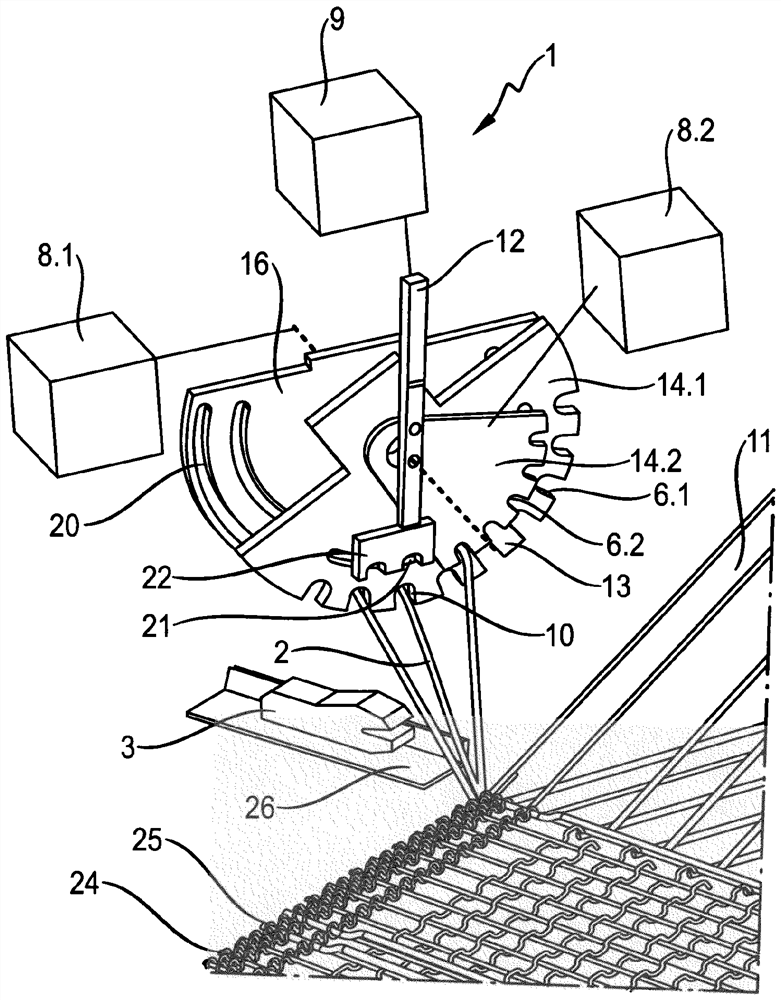

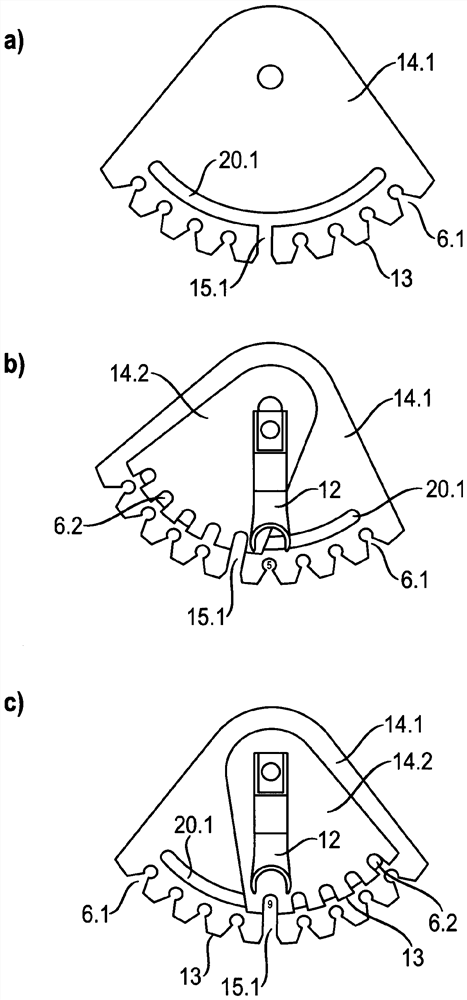

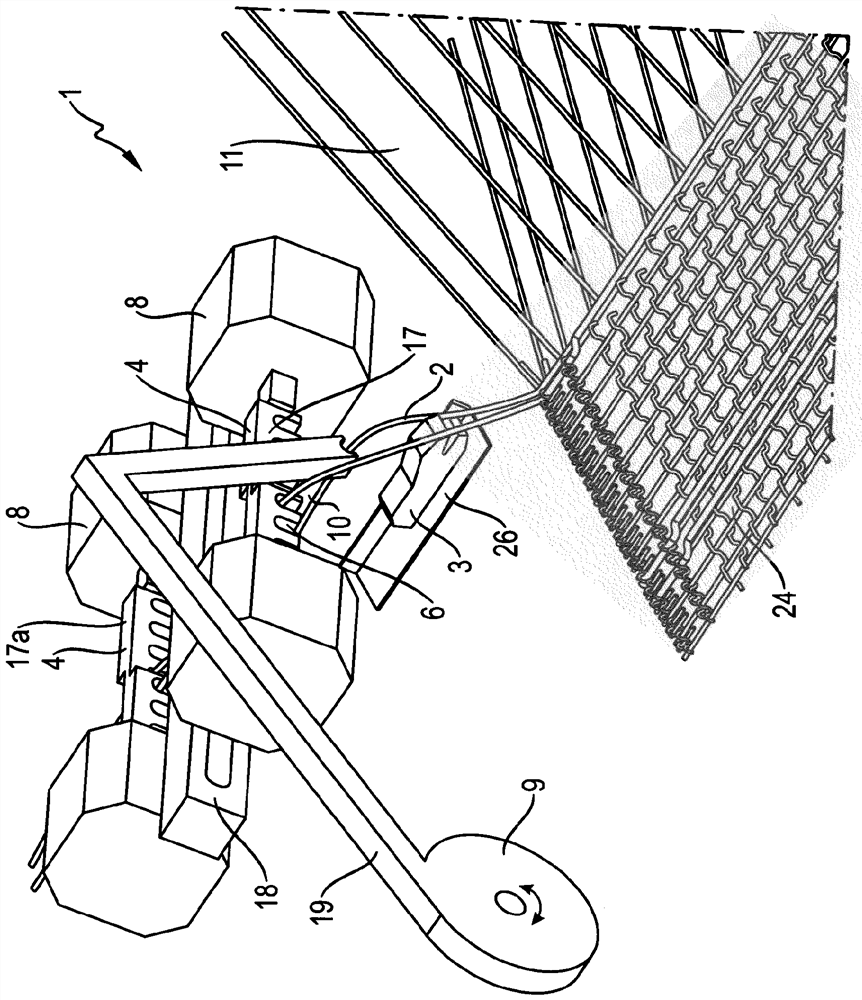

[0059] figure 1 Shown is a fabric section with a spread shed 11, in the case of a spread shed, next to which is shown a color wheel 14 according to the invention in the form of a color wheel 14 according to a first embodiment of the invention Weft color selection device 1. The color disc 14 is the actual thread guide 4 and has at its periphery guide holes 6 for the weft thread which is supplied to the weft thread color selection device 1 by a pre-winder not shown. Usually, there is a weft thread 2 in each thread guide hole 6 . The thread guide hole sinks into the color wheel 14 from the outer edge or the outer side 13 or the opening of the thread guide hole 6 .

[0060] In addition, the weft thread color selection device 1 has a delivery needle 12 which has at its front end a recess 21 which is configured in the form of a fork, so that once the color wheel 14 is in the delivery position 10, the delivery needle 12 passes through it towards the sheet The downward movement in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com