Vacuum cleaner nozzle

A vacuum cleaner and vacuum cleaner technology, applied in the field of vacuum cleaners and low-power vacuum cleaners, can solve the problem of not being able to easily enter hidden places, and achieve the effect of fast dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

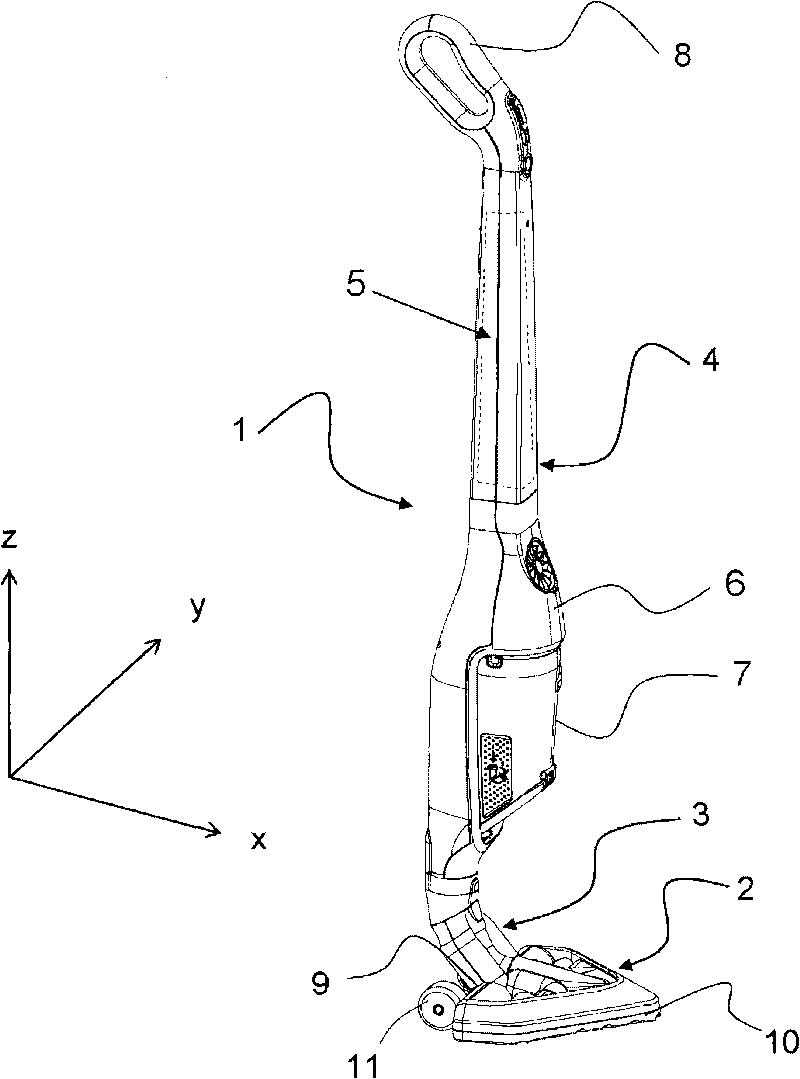

[0030] figure 1 A sweeping cleaner 1 is shown comprising a suction 2 in its lower part, which is connected to a handle 4 via an intermediate connection 3 . This handle 4 comprises a grip 8 at the upper end and forms a housing comprising: a battery 5, a motor 6 and means 7 for separating and storing waste, said housing being removable in order to be able to be cleaned. This handle 4 is articulated relative to the suction device 2 with several degrees of freedom and is directly manipulated by the user during sweeping in order to move said suction device 2 over the floor to be cleaned.

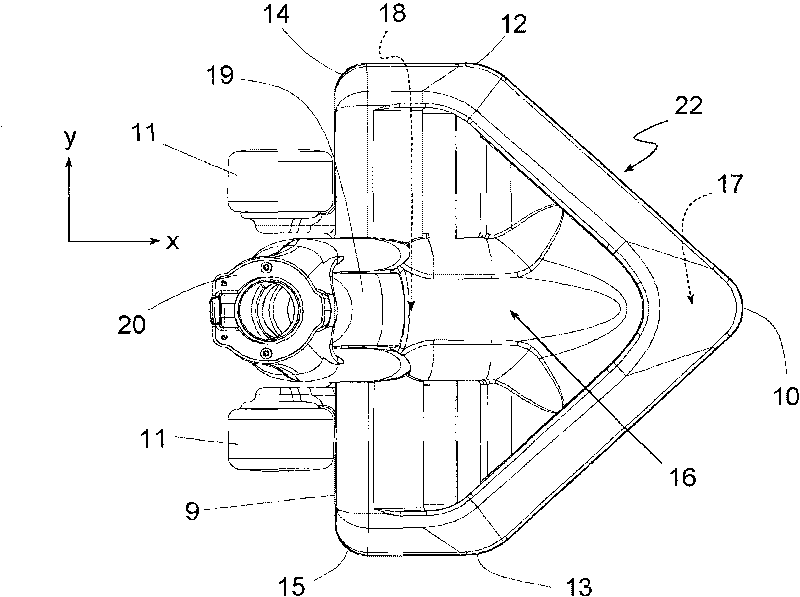

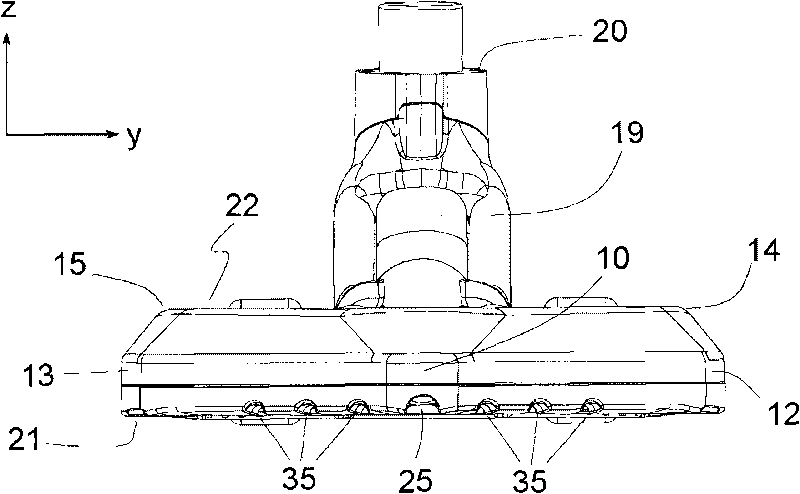

[0031] The aspirator 2 has a particular shape comprising a tip 10 for frontal orientation and a transverse edge 9 on which are mounted some wheels 11 for its advancement. For the purposes of the subsequent description, the longitudinal direction x is defined to mean the horizontal axis of symmetry of the aspirator oriented from rear to front, passing through the center of its rear edge 9 and its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com