Mechanism of shredder for detection of width and thickness of object to be shredded

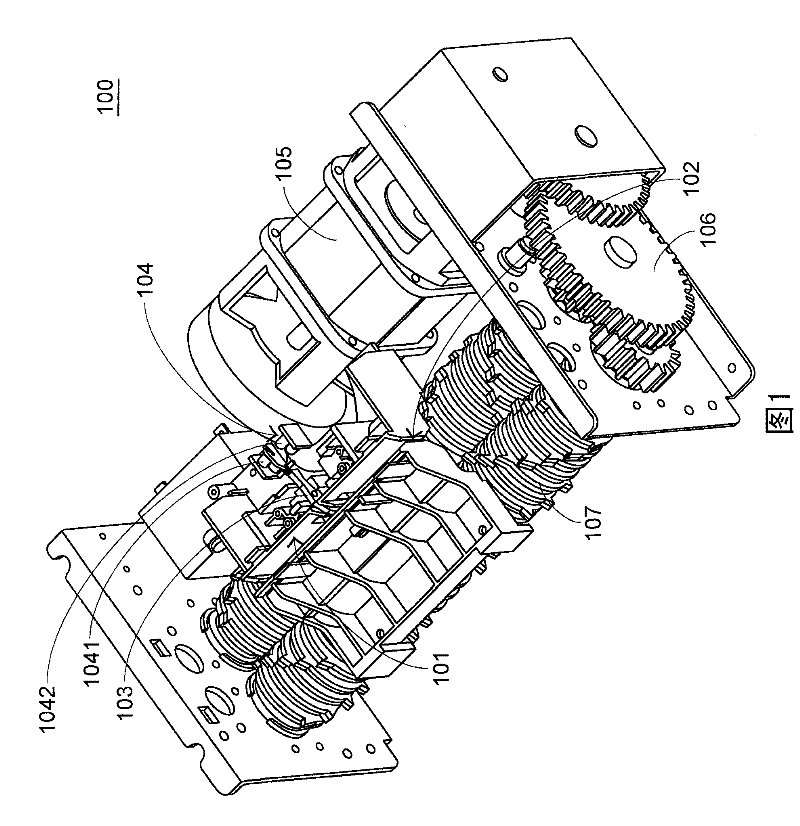

A thickness detection and shredder technology, applied in measuring devices, grain processing, instruments, etc., can solve problems such as paper jams or damage to the shredding cutter group 107, and achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

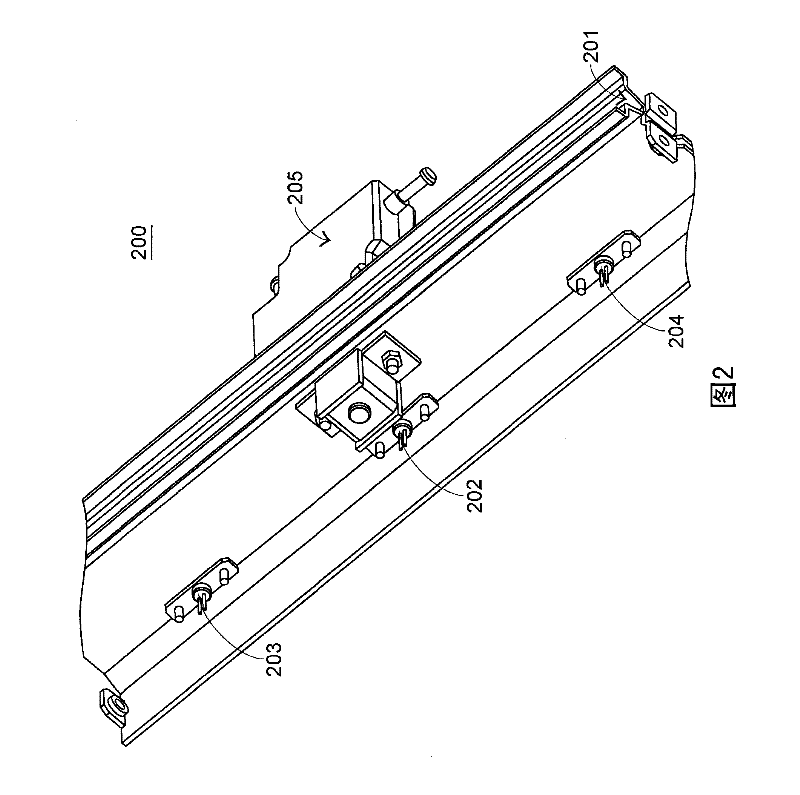

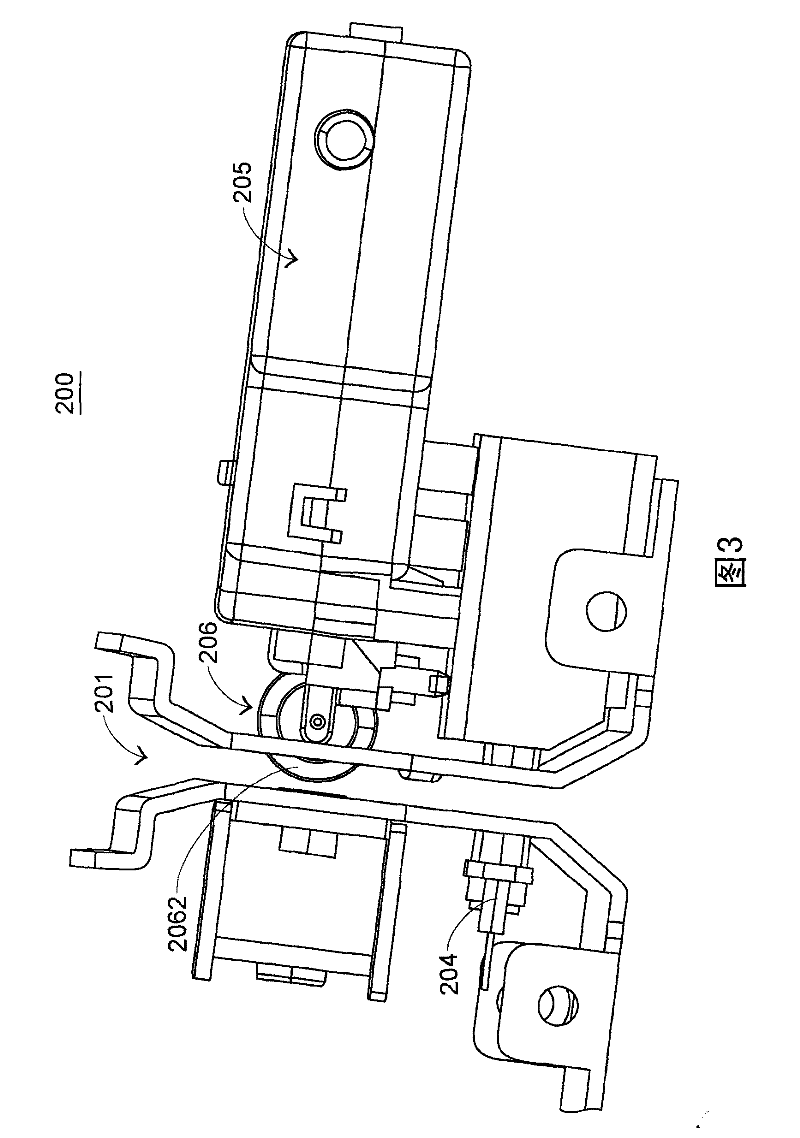

[0052] In view of the defects in the prior art, the present invention provides a detection mechanism capable of detecting the width of the object to be shredded, and the allowable thickness of the object to be shredded can be known according to the width of the object to be shredded. Please refer to FIG. 2 , which is a structural schematic diagram of a preferred embodiment of the detection mechanism for the width and thickness of the object to be shredded in the paper shredder of the present invention. The detection mechanism 200 includes a shredded paper channel 201, a first width sensor 202, a second width sensor 203, a third width sensor 204, a thickness detection module 205 and a control unit (not shown in the figure). The passage 201 is used to allow the objects to be shredded (not shown in the figure) to pass through for shredding. The first width sensor 202 is located on the shredding passage 201, and the second width sensor 203 is arranged on the first width sensing On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com