Automatic slippage control method suitable for rolling process of rough rolling

A rolling process, rough rolling technology, applied in the direction of rolling force/roll gap control, etc., can solve the problems of inaccurate control, uncontrollable slipping, easy wear, etc., achieve good effect, reduce maintenance cost, and reduce loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

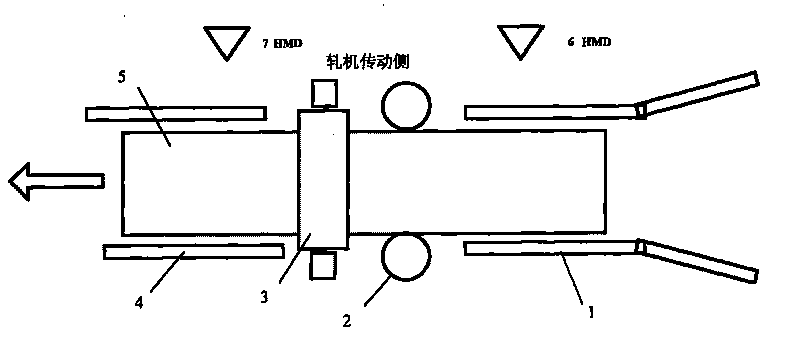

[0043] figure 1 It is a schematic diagram of the roughing mill and the guide plates on the entrance and exit sides, including the entrance side guide plate 1, the vertical rolling mill 2, the horizontal rolling mill 3, the exit side guide plate 4, the strip steel 5 (intermediate billet), and the entrance hot metal detector 6 (HMD) , export hot metal detector 7 (HMD).

[0044] figure 2 It is a schematic diagram of the adjustment device of the R2 roughing mill, including the hydraulic oil cylinder 8 (AGC oil cylinder) of the roughing mill, the lower horizontal roll 9, the upper and lower rolling mill roll gaps 10, and the upper horizontal roll 11.

[0045] In the present invention, the related equipment for rolling force judgment and slip control includes (not marked in the figure): pressure measuring head (rolling force dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com