Rectangular metal hose forming machine

A metal hose and molding machine technology, applied in the field of metal hose processing, can solve the problems of restricting the popularization and application of metal hose, difficult processing, complex structure, etc., and achieve fast and fast processing, high processing and molding quality, and simple and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

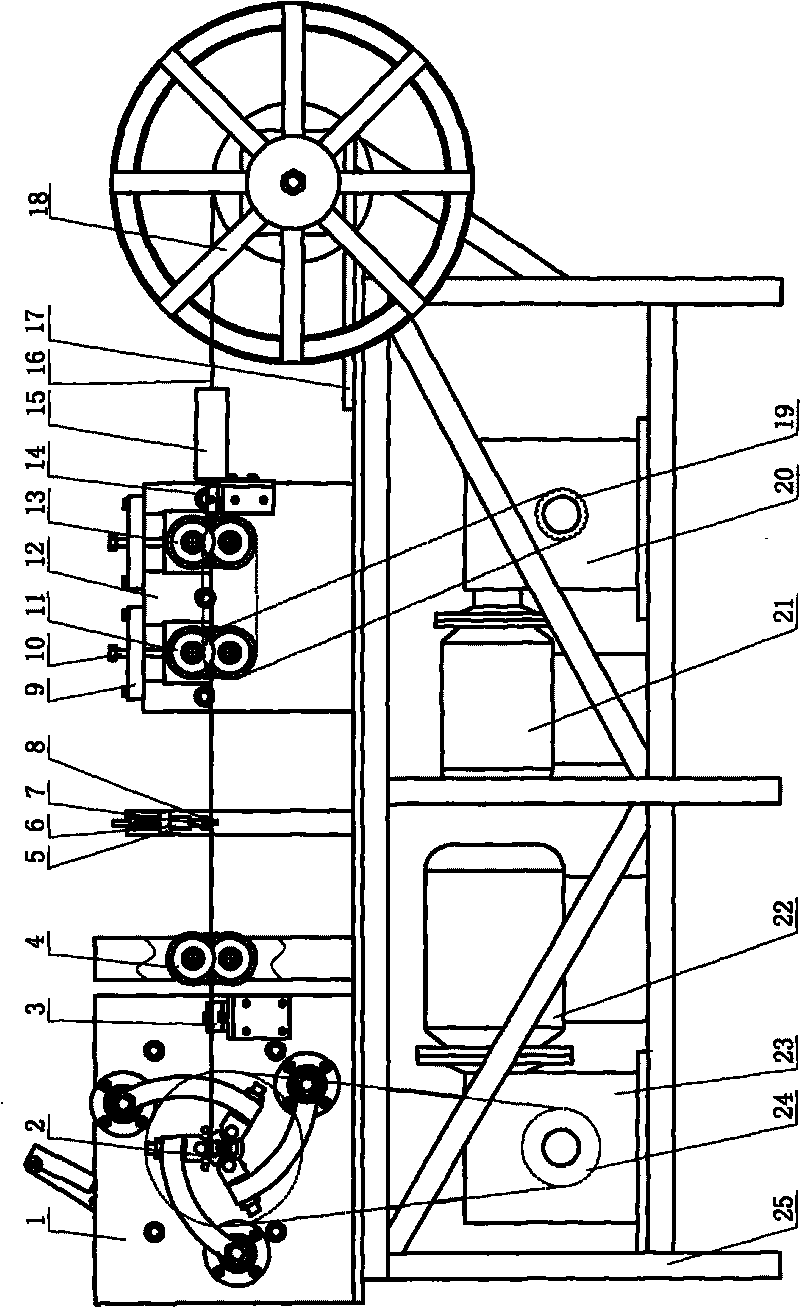

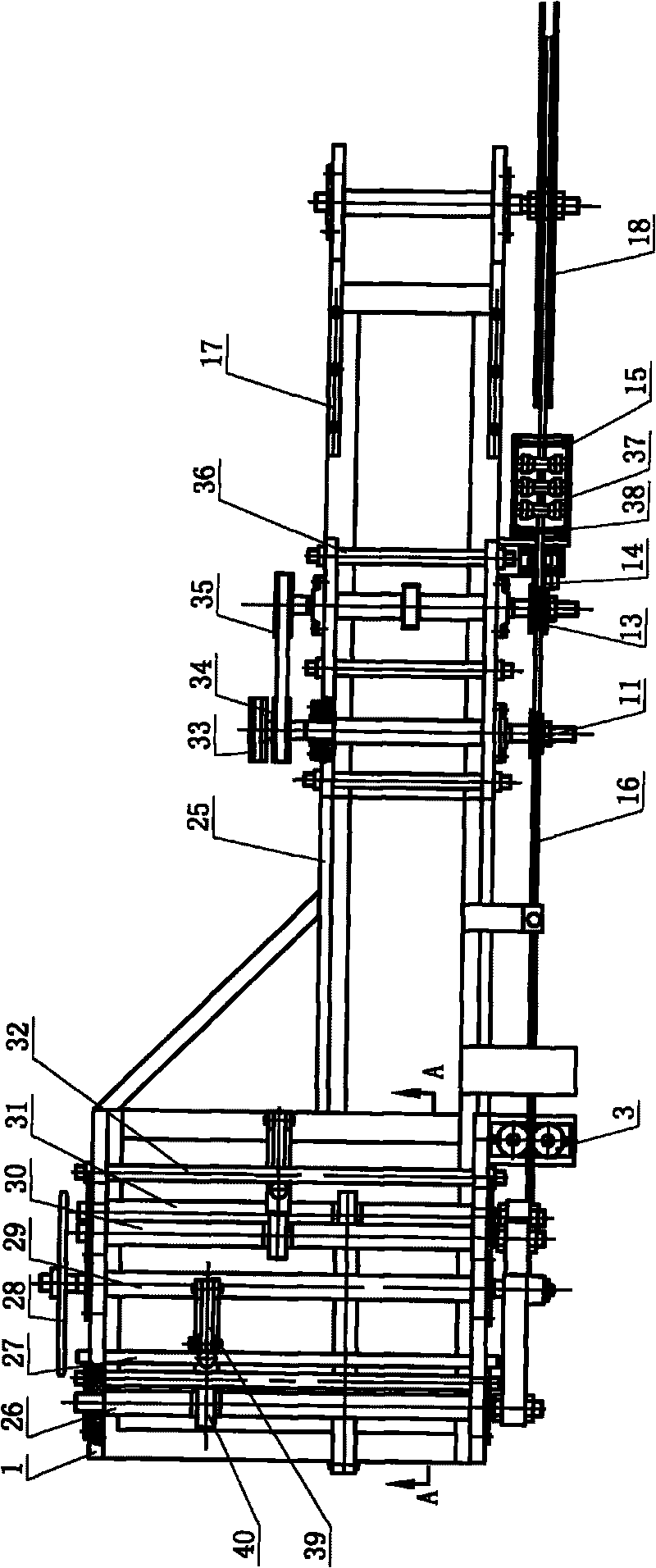

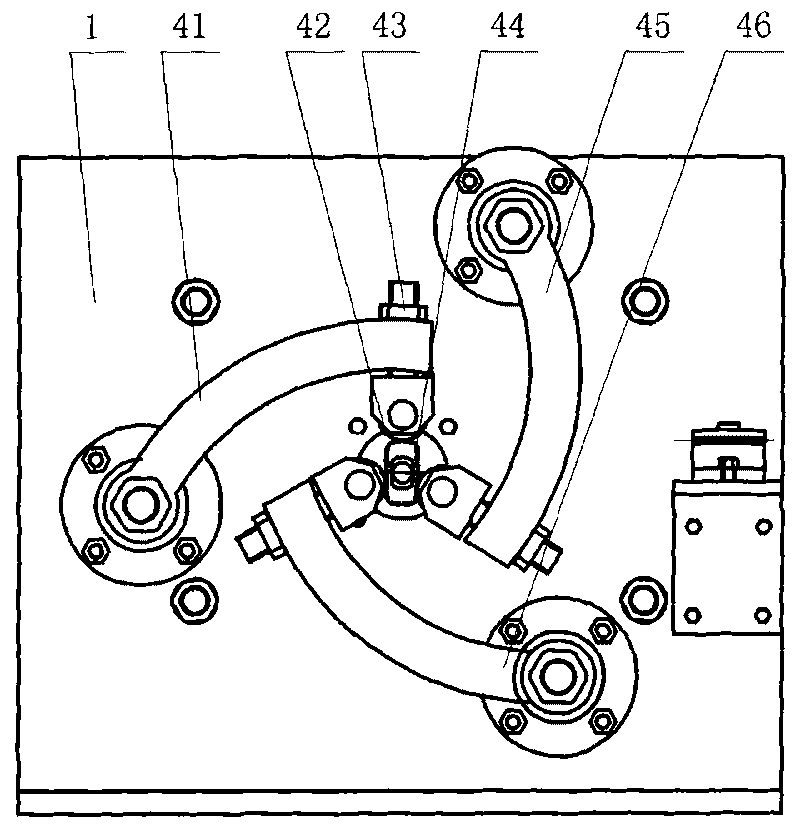

[0025] The rectangular metal hose forming machine is composed of a main frame 25, a material tray 18, a grooving roller, a hemming roller 3, a coil mechanism 2, a grooving roller driving motor 20 and a reducer 21 thereof, and the material tray, the grooving roller , Folding rollers, and coiling mechanism are installed on the main frame in sequence, and the groove roller drive motor and its reducer are fixed on the lower part of the main frame. The feed tray is wheel-shaped, and is installed on one side of the main frame by the feed tray support 17, and is wound with a metal blank 16, which is strip-shaped, and is delivered to the coiling mechanism through the groove roller and the flanging roller.

[0026] The grooving rolls include right-angle grooving rolls and round-angle grooving rolls 4 , and the right-angle grooving rolls include a primary ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com