Twin-wire melting pole gas shielded welding torch and welding method

A technology of gas shielded welding and welding torch, which is applied in the field of gas shielded welding equipment's welding torch and melting electrode gas shielded welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

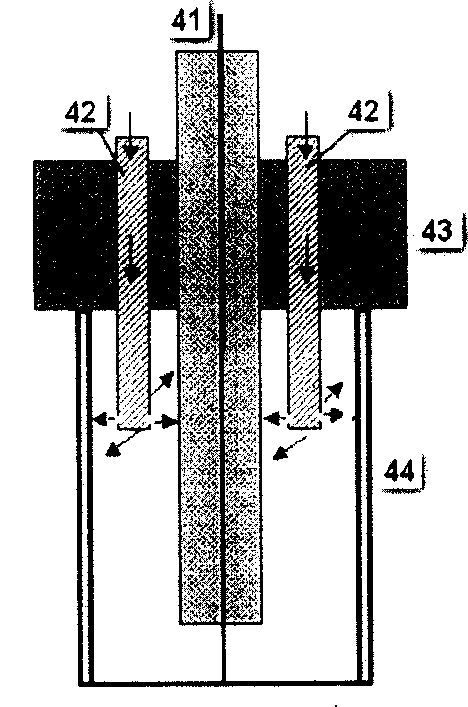

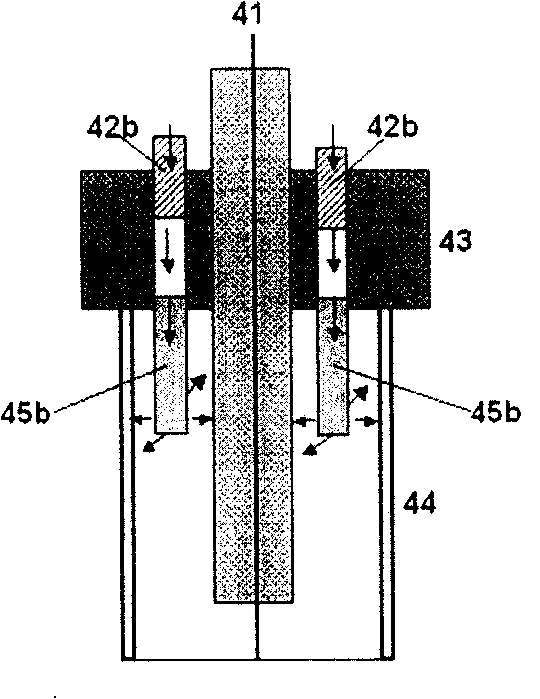

[0022] The referenced drawings are only used to illustrate preferred embodiments of the present invention, and are not intended to limit the present invention. Now refer to figure 1 with figure 2 , it can be seen that the reference numeral 100 represents the twin-wire welding torch assembly of the twin-wire gas shielded welding equipment according to the present invention.

[0023] figure 1 with figure 2 The illustrated twin wire torch assembly 100 includes two separate and parallel welding wire conduits 1 , two power cord connectors 4 , shielding gas nozzle 10 and two contact tips 12 . Although not in figure 1 with 2 As shown in , the twin-wire gas shielded welding equipment also has a wire feeding unit, which is used to independently provide two independent electrode welding wires to the welding torch, and the two welding wires are fed through the two welding wire conduits 1 The welding wire is driven to the respective contact tip 12 .

[0024] In one embodiment, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com