Weld joint tracking system based on image recognition and optimization method thereof

A tracking system and image recognition technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of complex system and high price of visual products, achieve fast data transmission, eliminate arc interference, and accurately weld track paths. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

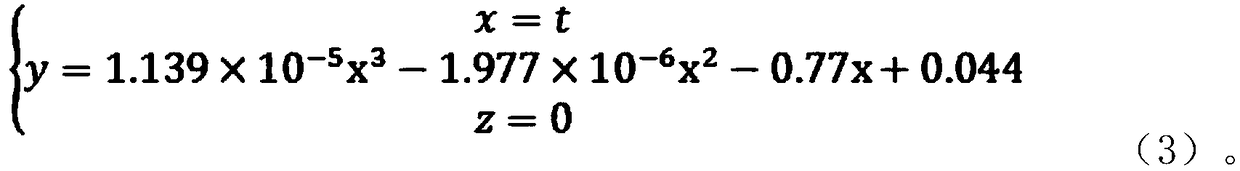

Examples

Embodiment 1

[0037] A welding seam tracking system based on image recognition, which includes: a visual sensor, a welding trolley, CO2 shielding gas, a tapped CO2 gas shielded welding torch, a wire feeder, a cross slide, a computing control box and a computer, and the visual sensor is installed on the tap The forward side of the type CO2 gas shielded welding torch, the tap type CO2 gas shielded welding torch is installed on the cross carriage, and the tap type CO2 gas shielded welding torch is driven by the cross carriage to move horizontally and vertically, and the cross carriage is connected with the calculation control box and the computer. The sensor is connected with the computer; the welding trolley carries the welding base metal to realize the movement of the welding direction.

[0038] Vision sensors include lasers, CCD cameras, optical filters and additional cooling, soot blowing and temperature control systems.

[0039] The visual sensor also includes an image acquisition card, a...

Embodiment 2

[0047] A welding seam tracking system based on image recognition, which includes: a visual sensor, a welding trolley, CO2 shielding gas, a tapped CO2 gas shielded welding torch, a wire feeder, a cross slide, a computing control box and a computer, and the visual sensor is installed on the tap The forward side of the type CO2 gas shielded welding torch, the tap type CO2 gas shielded welding torch is installed on the cross carriage, and the tap type CO2 gas shielded welding torch is driven by the cross carriage to move horizontally and vertically, and the cross carriage is connected with the calculation control box and the computer. The sensor is connected with the computer; the welding trolley carries the welding base metal to realize the movement of the welding direction.

[0048] Vision sensors include lasers, CCD cameras, optical filters and additional cooling, soot blowing and temperature control systems.

[0049] The visual sensor also includes an image acquisition card, a...

Embodiment 3

[0057] A welding seam tracking system based on image recognition, which includes: a visual sensor, a welding trolley, CO2 shielding gas, a tapped CO2 gas shielded welding torch, a wire feeder, a cross slide, a computing control box and a computer, and the visual sensor is installed on the tap The forward side of the type CO2 gas shielded welding torch, the tap type CO2 gas shielded welding torch is installed on the cross carriage, and the tap type CO2 gas shielded welding torch is driven by the cross carriage to move horizontally and vertically, and the cross carriage is connected with the calculation control box and the computer. The sensor is connected with the computer; the welding trolley carries the welding base metal to realize the movement of the welding direction.

[0058] Vision sensors include lasers, CCD cameras, optical filters and additional cooling, soot blowing and temperature control systems.

[0059] The visual sensor also includes an image acquisition card, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com