Manual brake

A technology of hand brake and control mechanism, which is applied in the direction of railway braking system, operating mechanism of railway vehicle brake, railway car body parts, etc. It can solve the problems that cannot meet the requirements, etc., and achieve good manufacturing interchangeability and simple operation , The effect of reducing assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

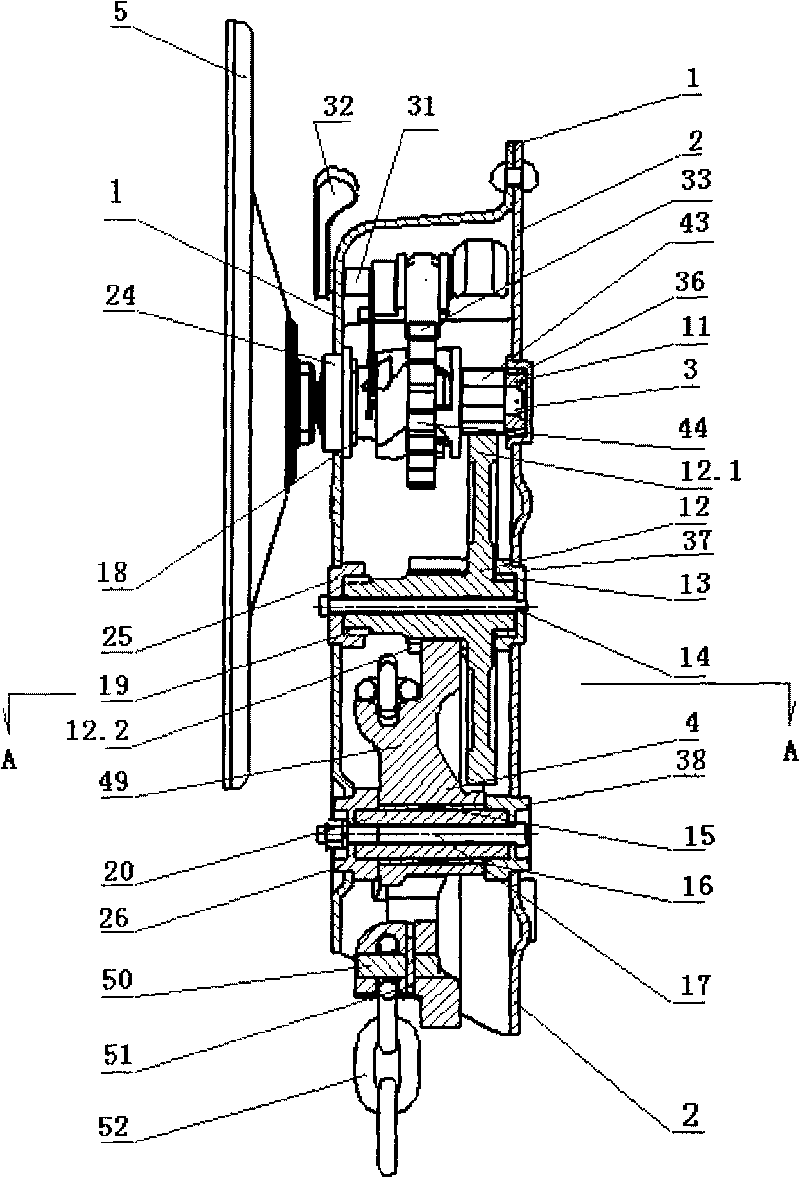

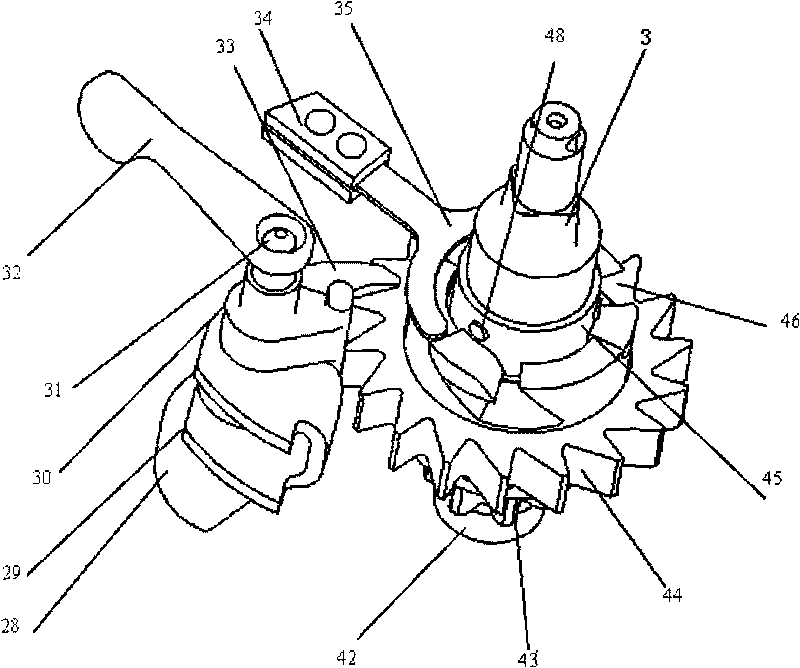

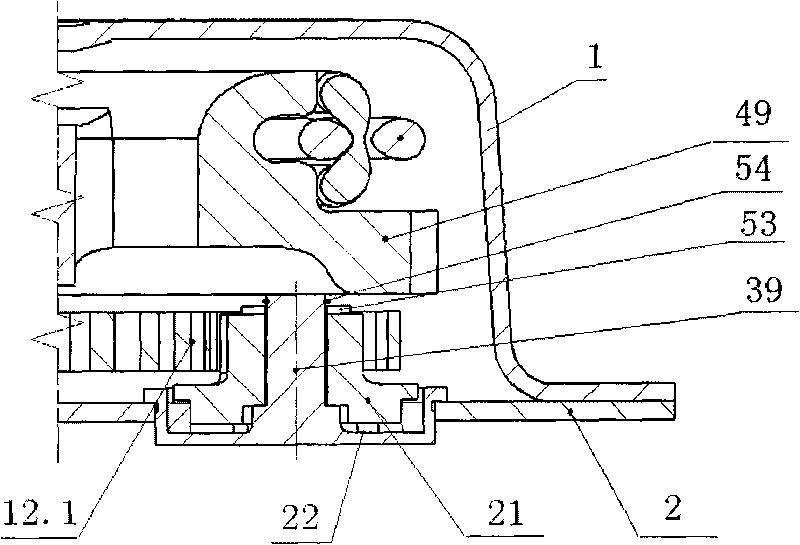

[0013] figure 1 It is a sectional view of the hand brake, which includes case shell assembly, intermediate shaft assembly, back plate assembly, main drive assembly and sprocket assembly. The box shell assembly includes a box shell 1 and a bearing seat fixed on the box shell 1 by welding. The backboard assembly includes a backboard 2, a bearing seat and the like. Case shell 1 and back plate 2 adopt profiled parts, driving shaft seat 24, intermediate shaft seat 25 and sprocket shaft seat 26 are respectively welded on case shell 1, and bearing seat 36, intermediate shaft seat 37 and sprocket shaft seat 38 are respectively welded on on the backplane 2.

[0014] The countershaft assembly includes the countershaft 12 of the hollow gear shaft, and the countershaft 12 has a high-speed bull gear 12.1 and a low-speed pinion 12.2. The main drive assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com