Pipe end riveting and assembling equipment

An assembly equipment and riveting technology, applied in metal processing equipment, other manufacturing equipment/tools, metal processing, etc., can solve the problems of unable to monitor pressure, unable to monitor size, and large product quality risks, so as to ensure assembly quality and action Fast, quick changeover effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

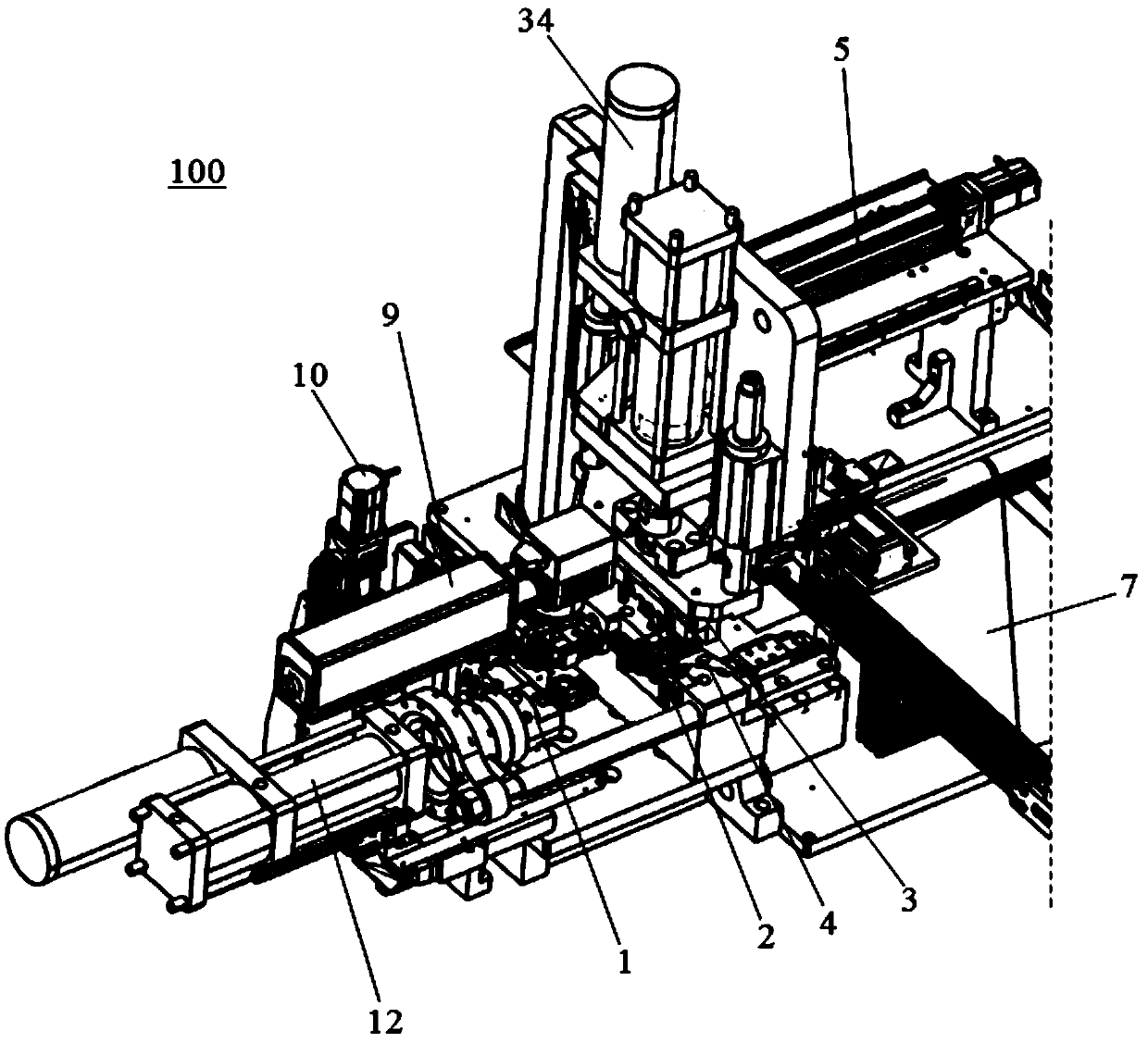

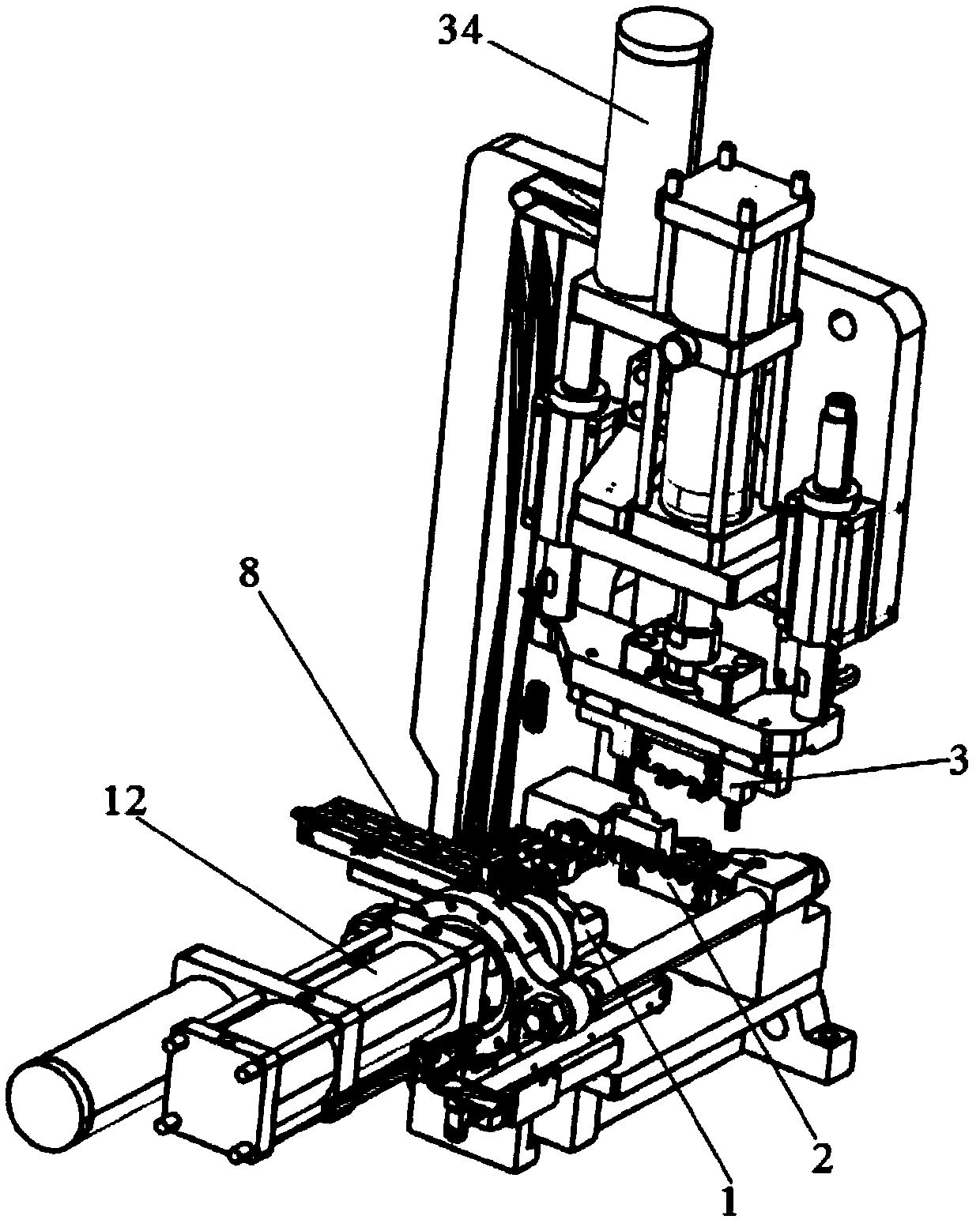

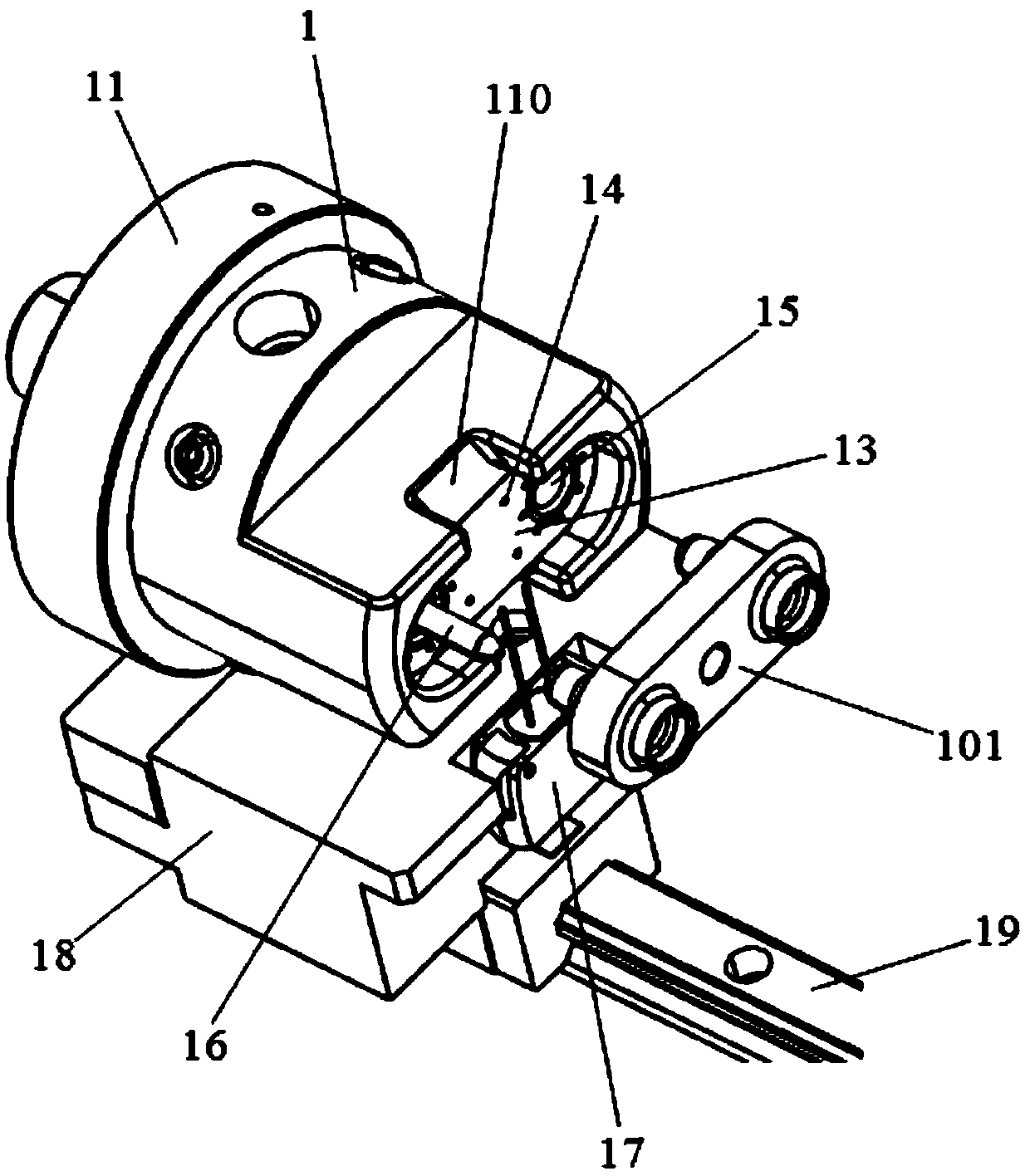

[0028] Please refer to Figure 1-Figure 7 , the present embodiment is a pipe end riveting assembly equipment 100, which includes an aluminum block die head 1 that can move left and right, a pier head lower die 2 that is opposite to the aluminum block die head 1, and a pier head lower die 2 that moves up and down and is connected to the pier head lower die. Die 2 cooperates with the upper die of the pier head that clamps the end of the aluminum tube 3, the aluminum pipe die that fixes the end of the aluminum tube and docks with the lower die 2 of the pier head 4, and detects whether there is any missing assembly at the end of the aluminum tube A detection mechanism (not marked in the figure), a grasping mechanism 5 that grabs the riveted products together, a second detection mechanism 6 that detects the size of the riveted products, and an automatic feeding device 7 .

[0029] The aluminum block die head 1 is sleeved on a module fixing block 11 , and the module fixing block 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com