Novel electroacoustic component automatic assembling production line

An electro-acoustic component, automatic assembly technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problem of insufficient height, reduce defective rate, etc., and achieve the effect of reducing energy consumption, improving efficiency, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

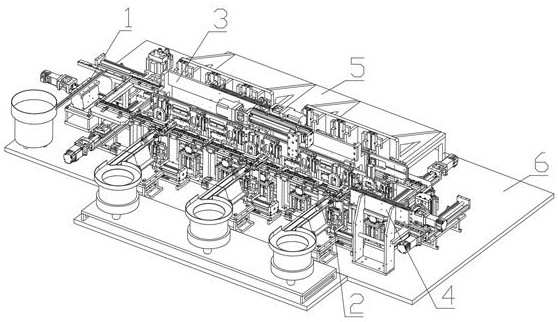

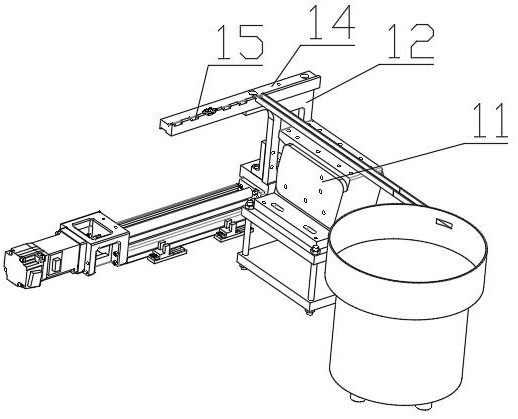

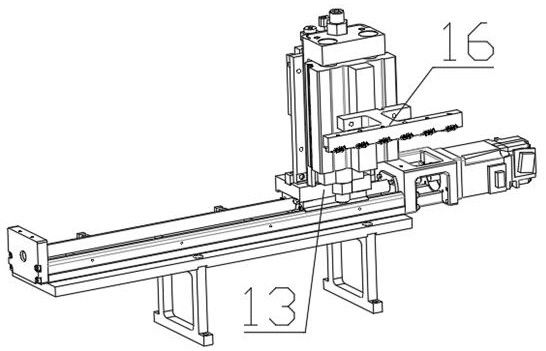

[0039] Example 1: as figure 1As shown in the figure, a new type of automatic assembly production line for electroacoustic components is provided with a female seat loading and unloading mechanism 1, a riveting socket feeding mechanism 2, a conveying mechanism 3, a flipping and reclaiming mechanism 4, a riveting and pressing mechanism 5 and a frame 6; the female seat The loading and unloading mechanism 1 is provided with a female base feeding vibration plate 11, a cloth carrier 12, and a loading and unloading robot 13; the cloth carrier 12 is provided with a first X-direction linear module and a cloth carrier 14, and the cloth carrier 14 is provided with There is a female seat carrier 15; the female seat feeding vibration plate transports the female seat to the cloth carrier, and the first X-direction linear module drives the cloth carrier 14 to move in the X direction, so that the female seat of the cloth carrier is placed on the carrier. Full of female seats; the loading and ...

Embodiment 2

[0040] Example 2: as figure 2 , image 3 As shown, a plurality of female seat carriers 15 are arranged on the cloth carrier, and the first X-direction linear module drives the cloth carrier to move in the X direction, and multiple female seats can be placed on the cloth carrier; Equipped with the same number of transfer suction head components, it can realize the feeding of multiple masters at one time, which is more efficient than transferring only one master at a time; and can reduce the power consumed by the frequent rotation of the equipment and reduce the kinetic energy consumption. consume.

Embodiment 3

[0041] Example 3: as Figure 5 As shown in the figure, the riveting socket carrier is provided with an even number of riveting sockets that are more than two, and it is necessary to drive the riveting socket feeding and vibrating plate discharge end of the riveting socket under the driving of the third X-direction linear module into the U-shaped groove. , If the position is offset, the riveting socket cannot accurately enter the U-shaped groove, so a paddle is set on the discharge track of the riveting socket feeding vibration plate, and the riveting socket carrier is driven by the third X-direction linear module. During the process, if the riveting socket does not enter the U-shaped groove, but is above the top plate, the pick can be pushed into the U-shaped groove after touching the riveting socket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com