Concrete modular brick and wall structure thereof

A concrete and wall technology, applied in building structures, walls, building components, etc., to achieve the effect of reducing energy-saving wall costs, wide adaptability, and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Embodiment 1, concrete modular brick specification and proportioning

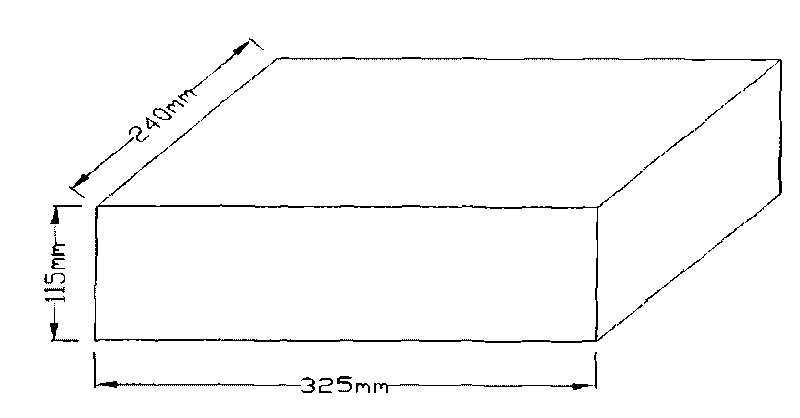

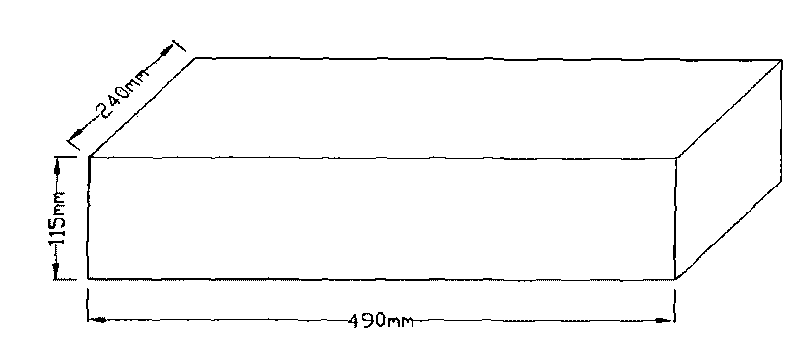

[0075] Such as figure 1 and 2 As shown, the concrete modular brick body of the present invention is a cuboid, and its length × width × height is 325mm × 240mm × 115mm. The top surface; or the length * width * height is 490mm * 240mm * 115mm, which is suitable for heating areas, wherein 490mm * 240mm is the large surface, 490mm * 115mm is the strip surface, and 240mm * 115mm is the top surface; in addition, the concrete modular brick of the present invention There are also two kinds of auxiliary specification block products, the length x width x height are 160mm x 240mm x 115mm and 80mm x 240mm x 115mm.

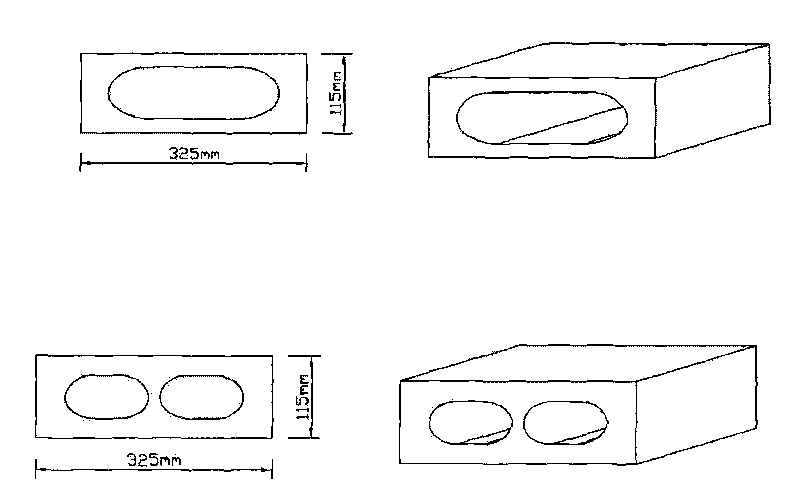

[0076] The concrete modular brick of the present invention can be a solid structure or a hollow structure. Such as image 3 As shown, the concrete modular brick with hollow structure is perpendicular to the 325mm×115mm brick surface and along the width (240mm) direction, set 1 or 2 vertical throu...

Embodiment 2

[0085] Embodiment 2, the preparation of concrete modular brick

[0086] Prepare concrete modular bricks as follows:

[0087] A, measure each component of the modular brick described in embodiment 1, add water according to the water-cement ratio 0.3-0.55, mix and stir evenly;

[0088] B. Stamping machine forming or pouring forming;

[0089] C. Natural curing or steam curing to produce corresponding concrete modular bricks.

Embodiment 3

[0090] Embodiment 3, the body of wall of concrete module brick masonry

[0091] Use concrete module brick of the present invention to build body of wall by laying bricks or stones, specifically as follows:

[0092] Such as Figure 4 As shown, the wall is built with the side length of 325mm of the modular brick as the thickness of the wall, which is in line with the thickness modulus of the light aggregate concrete wall for structural insulation in non-heating areas;

[0093] Such as Figure 5 As shown, take the side length of 490mm of the modular brick as the wall thickness and build the wall with two pieces of 240mm side length interval, which is in line with the thickness modulus of the self-insulation wall of light aggregate concrete in the heating area;

[0094] Such as Figure 6 As shown, the wall is built with the side length of 115mm of the modular brick as the thickness of the wall, which is in line with the thickness modulus of the non-load-bearing partition wall i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com