Well wall body module

A wall and shaft wall technology, which is applied in the field of shaft wall modules with improved and optimized structures, can solve the problems of large size difference between through holes and splicing holes, templates are prone to fracture and damage, and wall strength is uneven.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

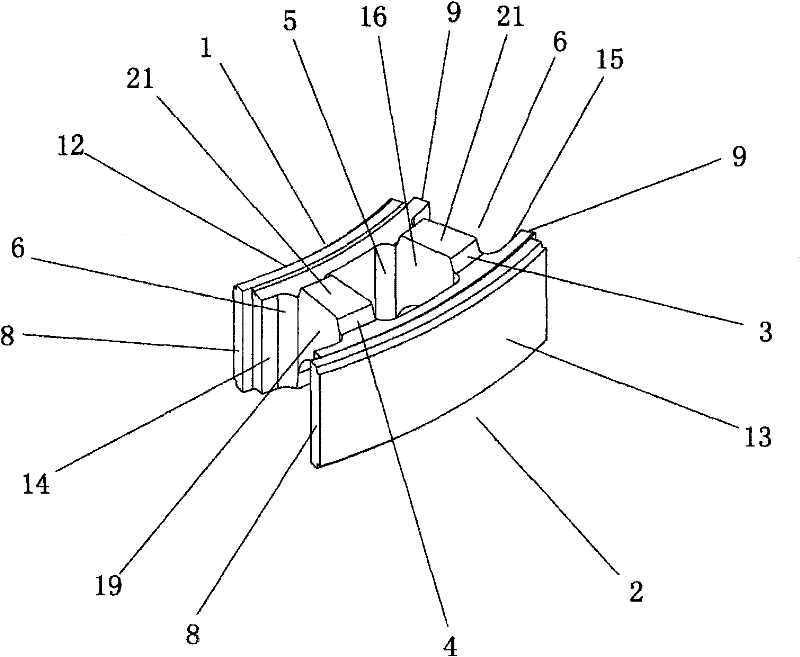

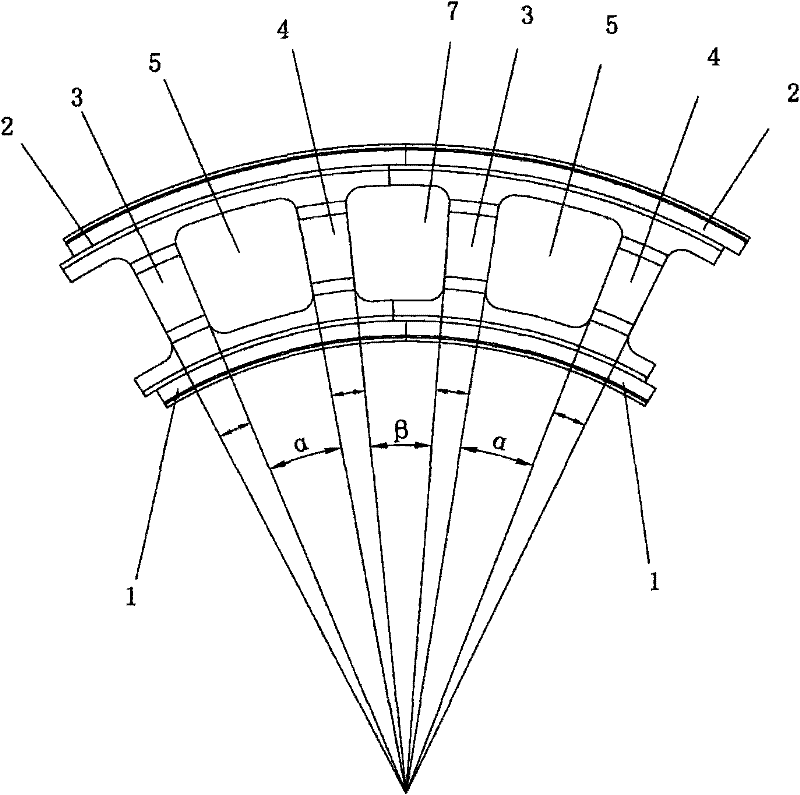

[0022] Such as figure 1 , figure 2 and image 3 As shown, the first shaft wall module of the present invention includes a front formwork 1, a rear formwork 2, a first rib 3 and a second rib 4, the front formwork 1 and the rear formwork 2 are coaxial circular arc formworks, the first The rib 3 and the second rib 4 are located between the front template 1 and the rear template 2, the first rib 3 and the second rib 4 connect the front template 1 and the rear template 2, there is a through hole 5 in the middle of the well wall module, and the well wall There are half holes 6 at both ends of the body module. When two well wall modules are connected together, the half holes 6 at the ends of the adjacent well wall modules form splicing holes 7; the two vertical surfaces of the first rib 3 The angle between the center of the circle and the angle between the two vertical surfaces of the second rib 4 are equal, that is, the angle between the center of the first inner surface 16 and t...

Embodiment 2

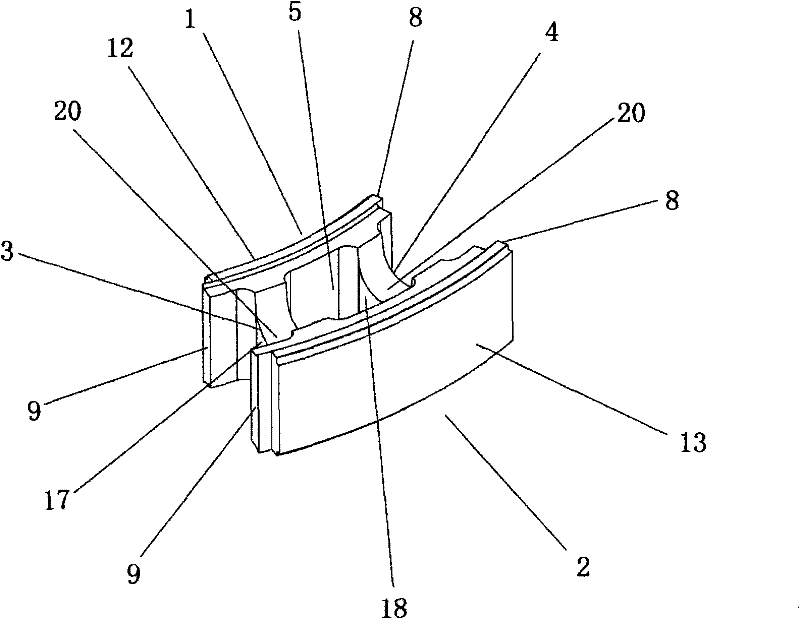

[0027] Such as Figure 4 , Figure 5 and Figure 6As shown, the second well wall module of the present invention includes a front formwork 1, a rear formwork 2, a first rib 3 and a second rib 4, the front formwork 1 and the rear formwork 2 are coaxial arc-shaped formworks, the first The rib 3 and the second rib 4 are located between the front template 1 and the rear template 2, the first rib 3 and the second rib 4 connect the front template 1 and the rear template 2, there is a through hole 5 in the middle of the well wall module, and the well wall There are half holes 6 at both ends of the body module. When two well wall modules are connected together, the half holes 6 at the ends of the adjacent well wall modules form splicing holes 7; the two vertical surfaces of the first rib 3 The angle between the center of the circle and the angle between the two vertical surfaces of the second rib 4 are equal, that is, the angle between the center of the first inner surface 16 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com