Mixing devices for selective catalytic reduction systems

A mixing device, selective technology, applied in the direction of mixers, exhaust devices, noise reduction devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following description is merely exemplary in nature and is not intended to limit the invention, its application or uses. It should be understood that throughout the drawings, like reference numerals indicate like or corresponding parts and features.

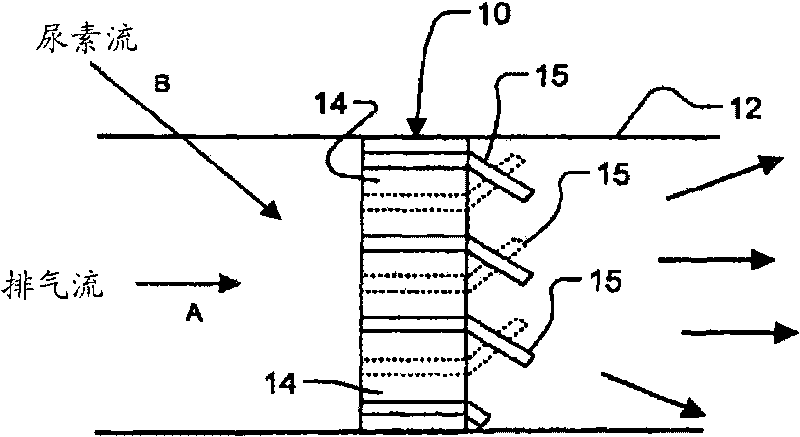

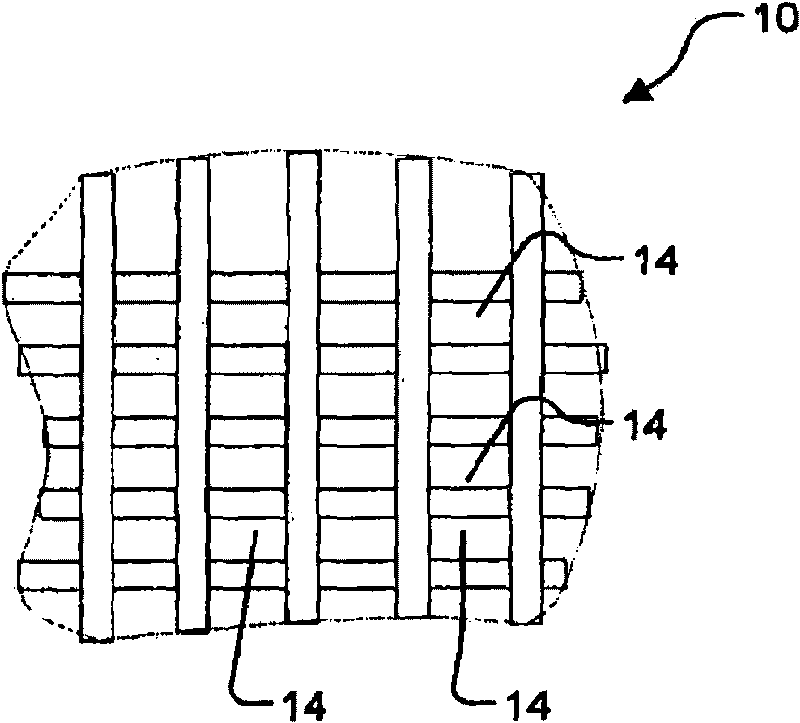

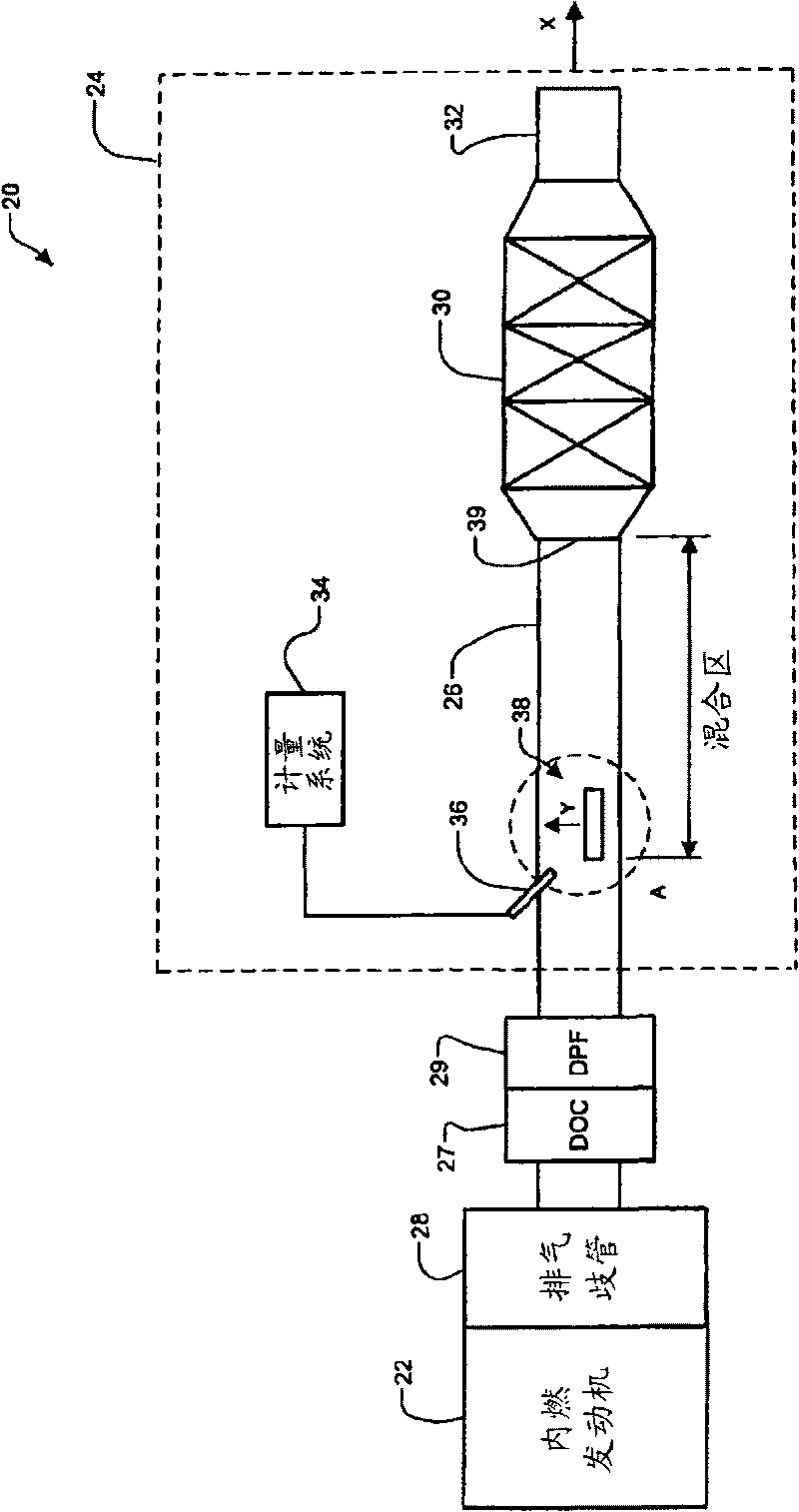

[0027] A mixing device for a selective catalytic reduction (SCR) system is provided in the exhaust pipe upstream of the SCR unit for mixing a urea solution with the exhaust gas. The mixing device includes a perforated body and a plurality of tabs extending outwardly from the perforated body. The apertured body has a first surface, a second surface, and a plurality of channels extending from the first surface to the second surface. The first surface and the second surface are parallel to each other and at an angle to the wall of the exhaust pipe. This angle is less than 90 degrees. This angle can be 0 degrees to reduce pressure drop. The mixing device of the present invention achieves better vaporization and distrib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com