Brake

A technology of brakes and brake teeth, which is applied in the direction of brake types, brake components, brake actuators, etc., can solve the problems of difficult control, not so fast response time of the motor, and poor control accuracy, so as to improve the response performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

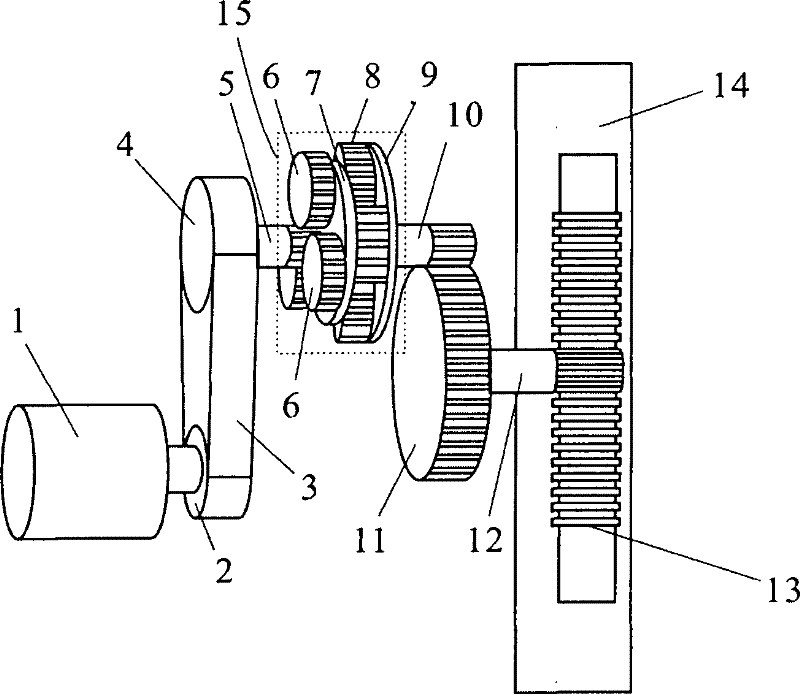

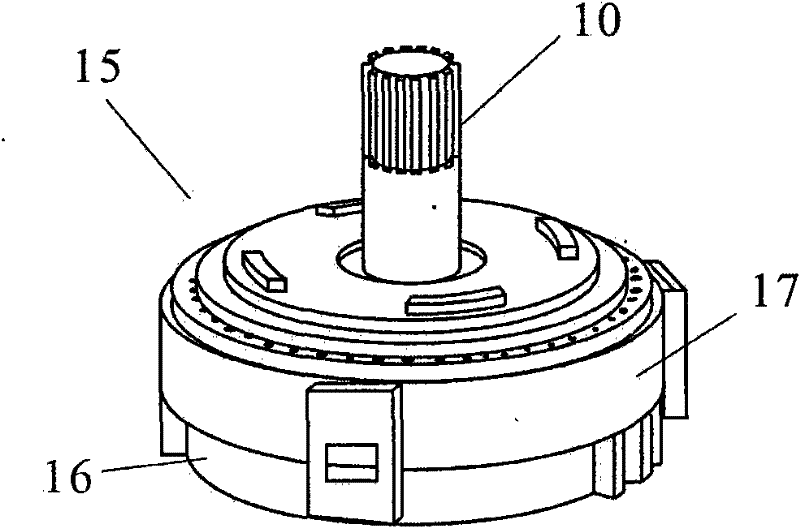

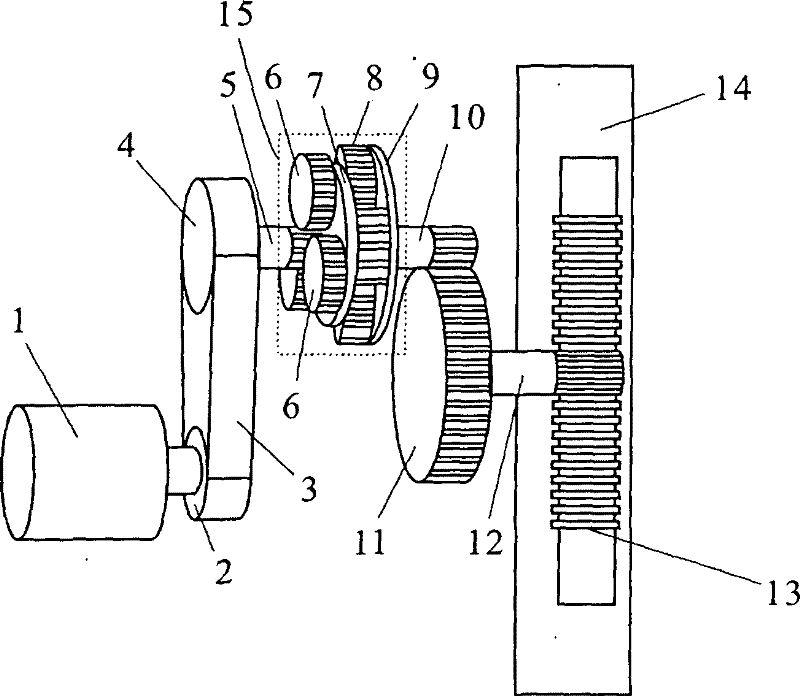

[0013] Please also refer to figure 1 with figure 2 , as shown in the figure, a brake includes a mechanical transmission mechanism and a brake rack push rod mechanism. The mechanical transmission mechanism includes a drive motor 1, a first transmission gear 2 driven by the drive motor 1, and the first transmission gear 2 The drive belt 3 engaged with the drive belt 3, the second transmission gear 4 driven by the drive belt 3; the brake rack push rod mechanism further includes the first sun gear 5 driven by the second transmission gear 4, and the first sun gear 5 is installed The connected deceleration torque increasing mechanism 15, the first reduction gear 10 protruding from the deceleration torque increasing mechanism 15, the second reduction gear 11 meshing with the first reduction gear 10, the third reduction gear driven by the second reduction gear 11 12. The gear rack 13 used for braking the brake pads 14 moves through the meshing belt; the deceleration and torque-incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com