Rotating angle sensor

A technology of rotation angle and sensor, which is applied in the direction of instruments, mechanical devices to transmit sensing components, measuring devices, etc., which can solve the problems of rotation angle sensor measurement deviation, failure, and low detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

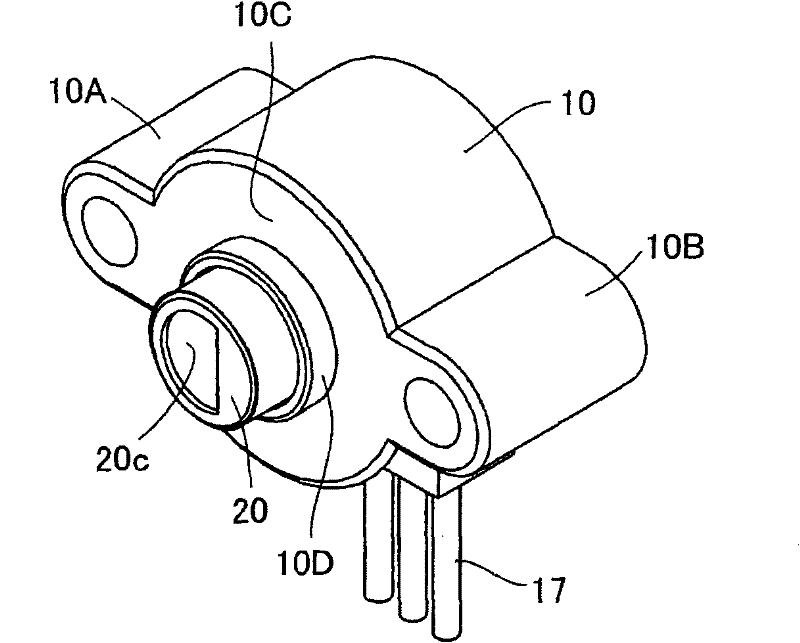

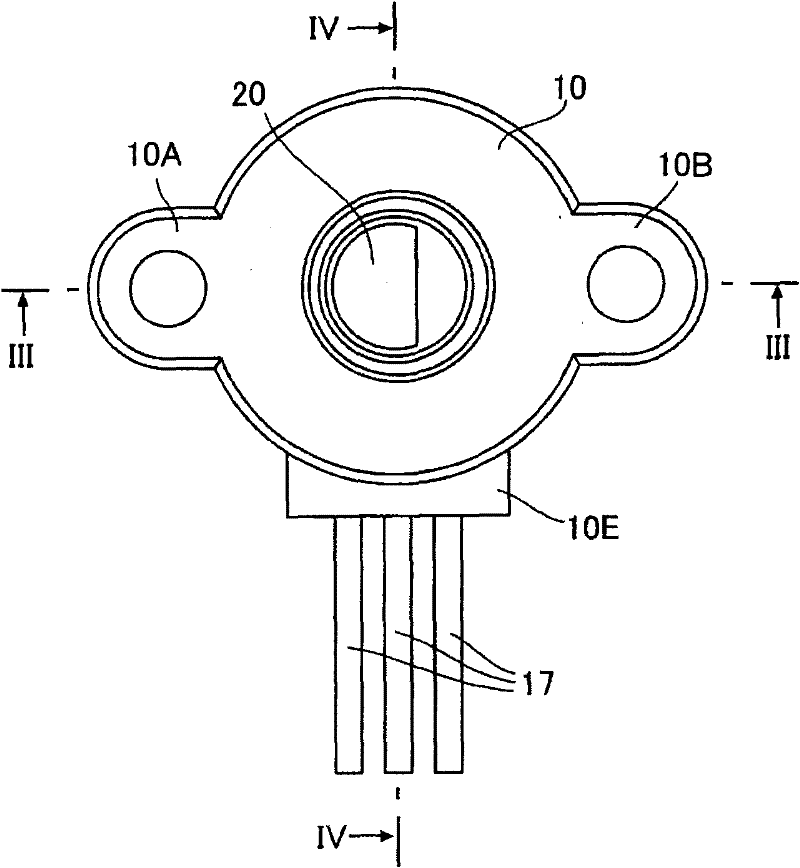

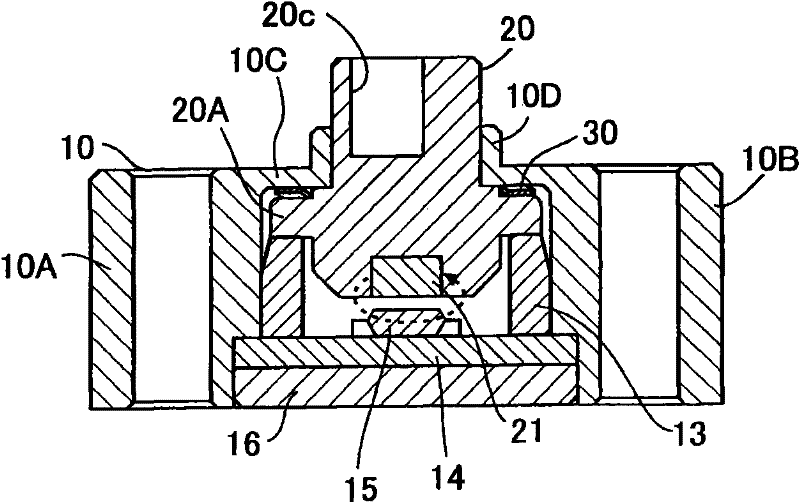

[0017] figure 1 Represent the perspective view of the first embodiment of the rotation angle sensor of the present invention, figure 2 represents its floor plan, image 3 and Figure 4 Respectively figure 2 III-III section and IV-IV section of the rotation angle sensor in Fig. The rotation angle sensor has: a case 10 formed of a substantially cylindrical insulator having mounting protrusions 10A, 10B on both sides; ; The wave washer (wave seat gold) 30 installed between the flange 20A formed at the axially middle part of the rotor 20 and the front wall of the housing 10; the magnet 21 fixed to the other end of the rotor 20 located in the housing 20; The ring bearing 13 that supports the inner end of the rotor 20 through one end in the casing 10; the wiring board 14 that supports the other end of the ring bearing 13; A magnetic sensor IC 15 (integrated circuit) mounted on the wiring board 14 facing at a distance from each other;

[0018] In addition, in Figure 8 In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com