Method and system for detecting cavitation of pump and frequency converter

A frequency converter, cavitation technology, applied in the field of methods and systems, to achieve the effect of eliminating demand and reliable detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

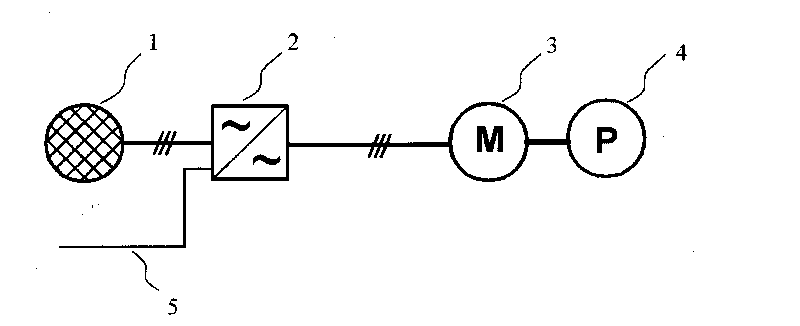

[0021] figure 1 The basic structure of a pump driven by a frequency converter is shown. The frequency converter 2 is connected to a supplying network 1 via a three-phase cable. The frequency converter is also connected to the motor 3 which in turn is mechanically connected to the pump 4 . Frequency converters control the rotation of motors and pumps in a desired manner. The frequency converter is also connected to the automation system via the interface 5 . An automation system can be a higher level controller that controls the process to which the pump is associated. Thus, the automation interface gives instructions for the operation of the pump, which is managed by the frequency converter. exist figure 1 In , all measurements of the system are omitted, and the motor and the pumping process are controlled in a sensorless manner.

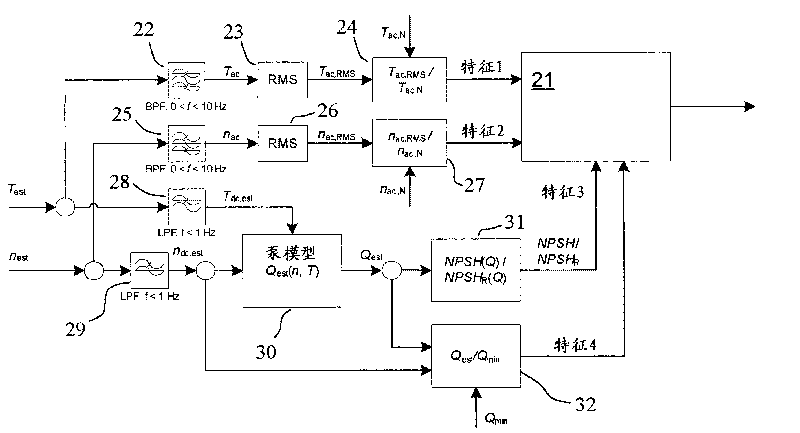

[0022] figure 2 is a block diagram presenting the process performed in the present invention. In the present invention, the frequency conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com