Zoom infrared optical system, zooming device and manufacturing method thereof

An infrared optical system and variable focal length technology, applied in optics, optical components, installation, etc., can solve the problems of limited field of view and the number of moving components, long axial length of zoom lens group, and limited freedom of optical design. , to achieve the effect of increasing the telephoto transmittance, reducing the number of system lenses, and improving the detection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is further described as follows in conjunction with accompanying drawing and embodiment:

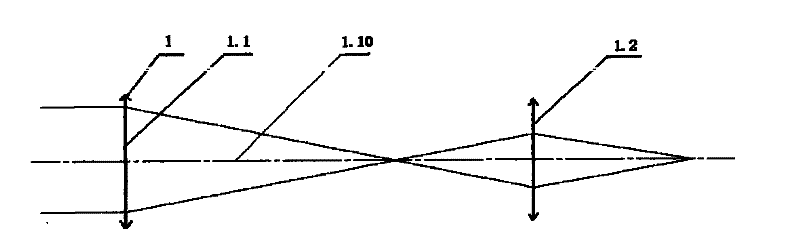

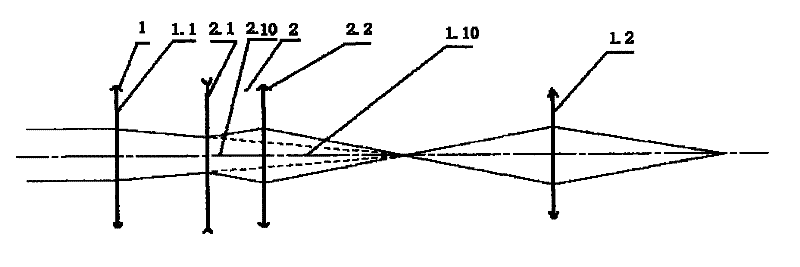

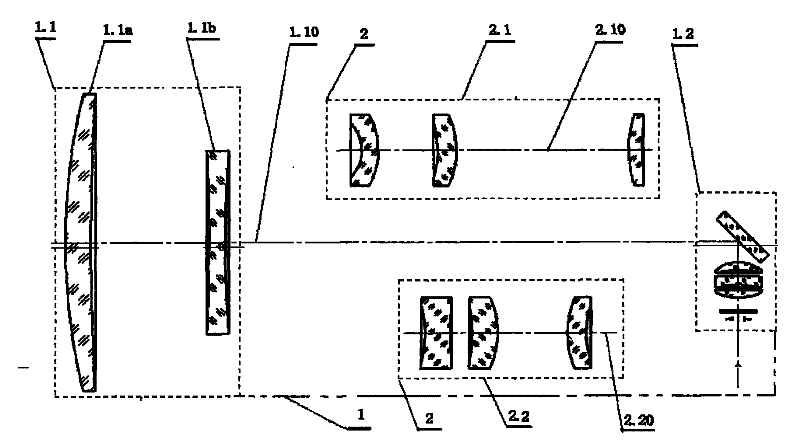

[0046] Such as figure 1 , 2 , Shown in 3, is an embodiment of a kind of zoom infrared optical system of the present invention:

[0047] A zoom infrared optical system, it has a telephoto lens group 1 and zoom lens group 2, the lens materials are optical materials that can work in the infrared band; the telephoto lens group 1 is composed of front fixed lens group 1.1 and The rear fixed lens group 1.2 constitutes; the variable power lens group 2 is located between the front fixed lens group 1.1 and the rear fixed lens group 1.2: when telephoto imaging, the variable power lens group 2 is located between the front fixed lens group 1.1 and the rear fixed lens group 1.2 Outside the optical path between; when zooming imaging, the variable power lens group 2 cuts in the optical path between the front fixed lens group 1.1 and the rear fixed lens group 1.2 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com