Pulse width modulating switch power source and power supply control method thereof

A technology of pulse width modulation and switching power supply, which is applied in the direction of electrical components, output power conversion devices, and conversion of AC power input to DC power output. It can solve the problems of increasing switching energy loss, low power supply efficiency, and failure to achieve global optimization. problems, to achieve the effects of improving usage efficiency, optimizing power usage efficiency, and global optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] In the first embodiment, the case where the upper transistor is formed by two MOSFETs connected in parallel and the lower transistor is one MOSFET is described in detail.

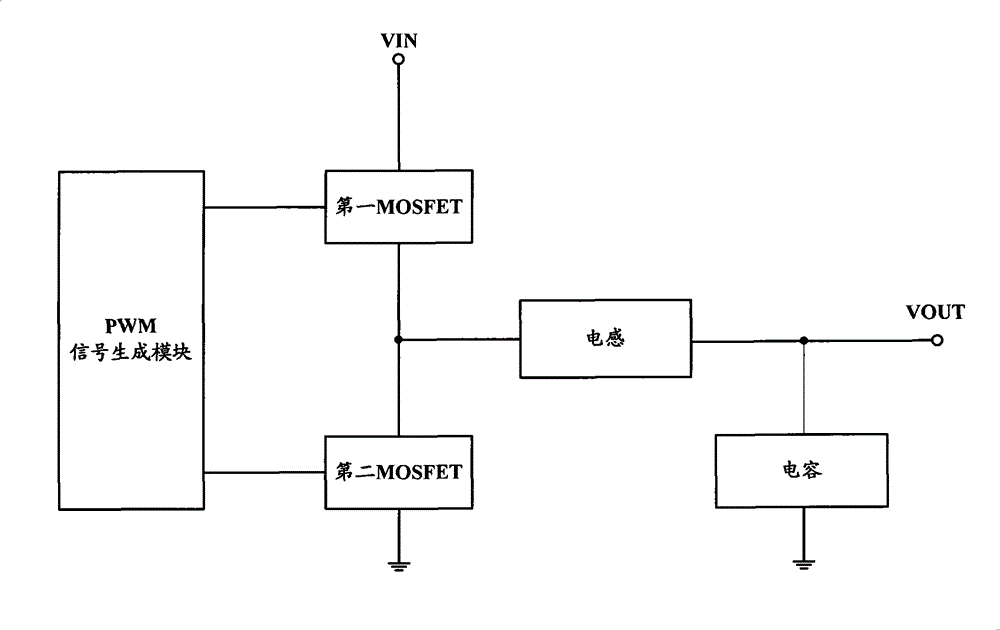

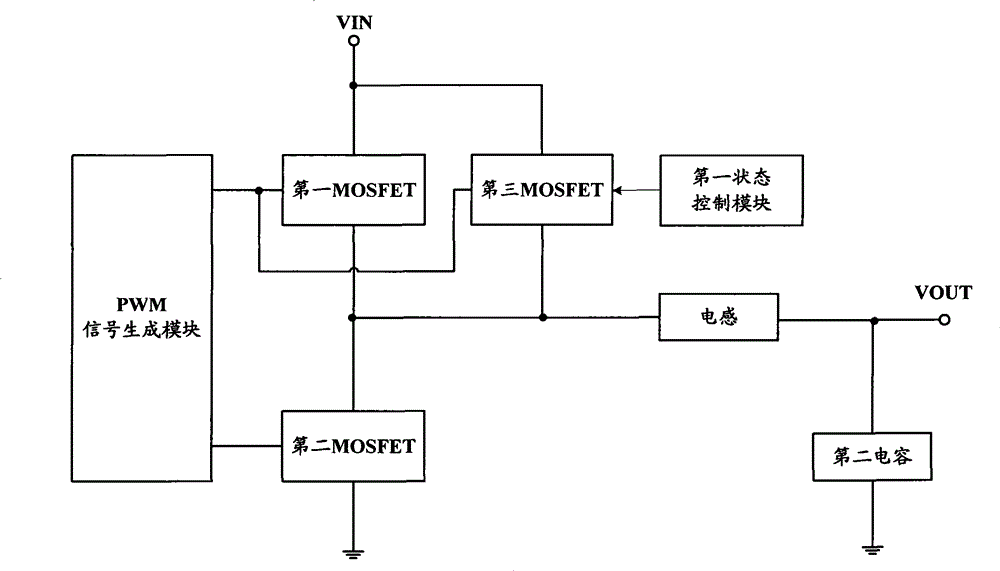

[0075] The pulse width modulation switching power supply of the first embodiment of the present invention is as follows: image 3 shown, including:

[0076] a PWM controller, configured to generate and generate a first PWM signal and a second PWM signal that is inverted from the first PWM signal, and output the first PWM signal and the second PWM signal;

[0077] a MOSFET group including a first MOSFET, a second MOSFET and a third MOSFET;

[0078] A first MOSFET (Metallic Oxide Semiconductor Field Effect Transistor, Metal Oxide Semiconductor Field Effect Transistor) and a second MOSFET, the gates of the first MOSFET and the second MOSFET receive the first PWM signal and the second PWM signal ( That is, the gate of the first MOSFET is used to receive the first PWM signal, the gate of the second MOSF...

Embodiment 2

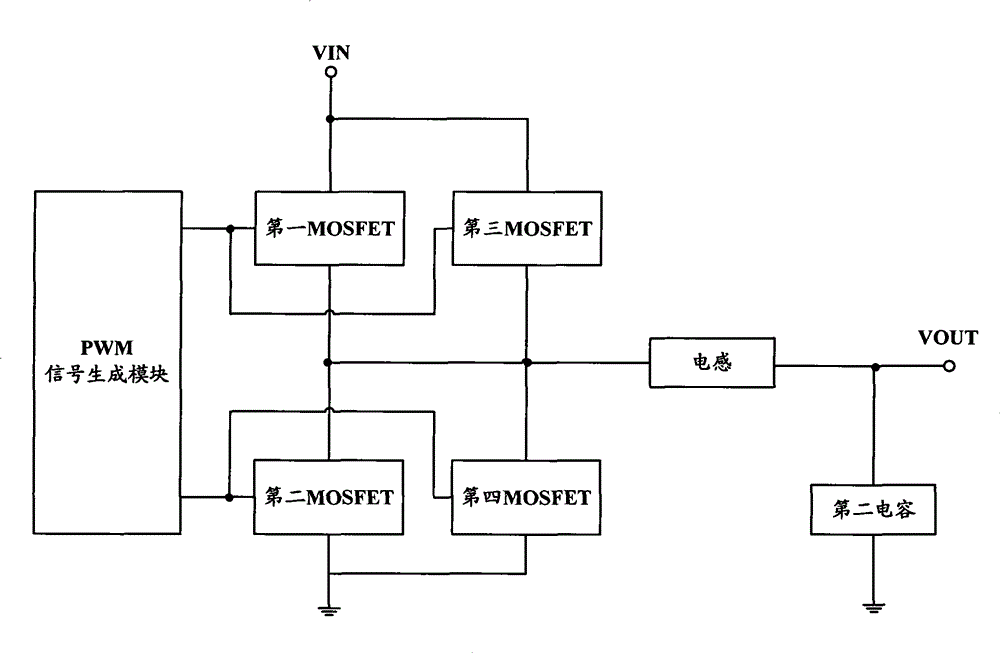

[0117] In the second embodiment, the case where two parallel-connected MOSFETs constitute the upper transistor and two parallel-connected MOSFETs constitute the lower transistor will be described in detail.

[0118] The pulse width modulation switching power supply of the second embodiment of the present invention is as follows: Figure 4 shown, including:

[0119] a PWM controller, configured to generate and generate a first PWM signal and a second PWM signal that is inverted from the first PWM signal, and output the first PWM signal and the second PWM signal;

[0120] a MOSFET group including a first MOSFET, a second MOSFET, a third MOSFET and a fourth MOSFET;

[0121] A first MOSFET (Metallic Oxide Semiconductor Field Effect Transistor, Metal Oxide Semiconductor Field Effect Transistor) and a second MOSFET, the gates of the first MOSFET and the second MOSFET respectively receive the first PWM signal and the second PWM signal, And the first terminal of the first MOSFET is ...

Embodiment 3

[0171] In the third embodiment, the case where at least three MOSFETs connected in parallel constitute the upper transistor and at least three MOSFETs connected in parallel constitute the lower transistor will be described in detail.

[0172] The pulse width modulation switching power supply of the third embodiment of the present invention is as follows: Figure 5 As shown, considering the simplicity of the figure, the FETs in the figure represent MOSFETs, including:

[0173] a PWM controller, configured to generate and generate a first PWM signal and a second PWM signal that is inverted from the first PWM signal, and output the first PWM signal and the second PWM signal;

[0174] a MOSFET group comprising a first MOSFET, a second MOSFET, a first set of MOSFETs, and a second set of MOSFETs;

[0175] A first MOSFET (Metallic Oxide Semiconductor Field Effect Transistor, Metal Oxide Semiconductor Field Effect Transistor) and a second MOSFET, the gates of the first MOSFET and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com